Mask plate cleaning system

A cleaning system and mask technology, applied in the field of cleaning equipment, can solve problems such as the inability to effectively clean FineMask or mask, increase the production cost of OLED display screens, affect the quality of OLED display screens, etc., achieve continuous and automatic control, reduce Cleaning cost, effect of improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

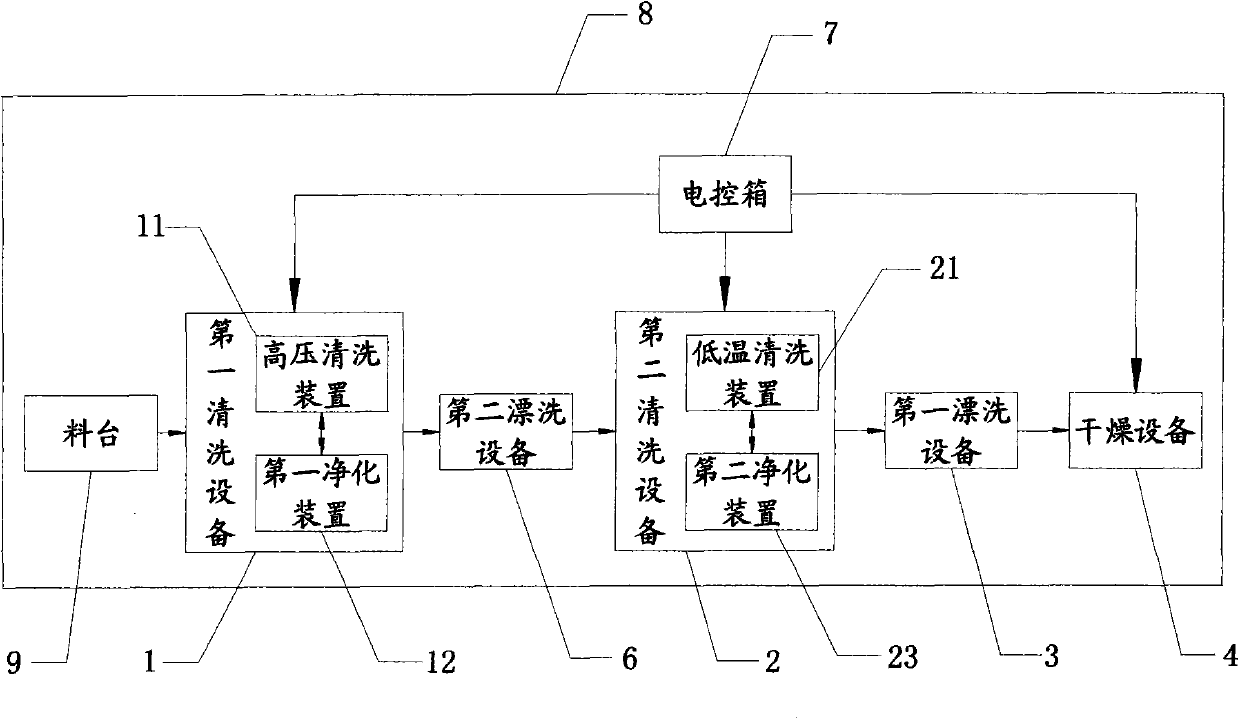

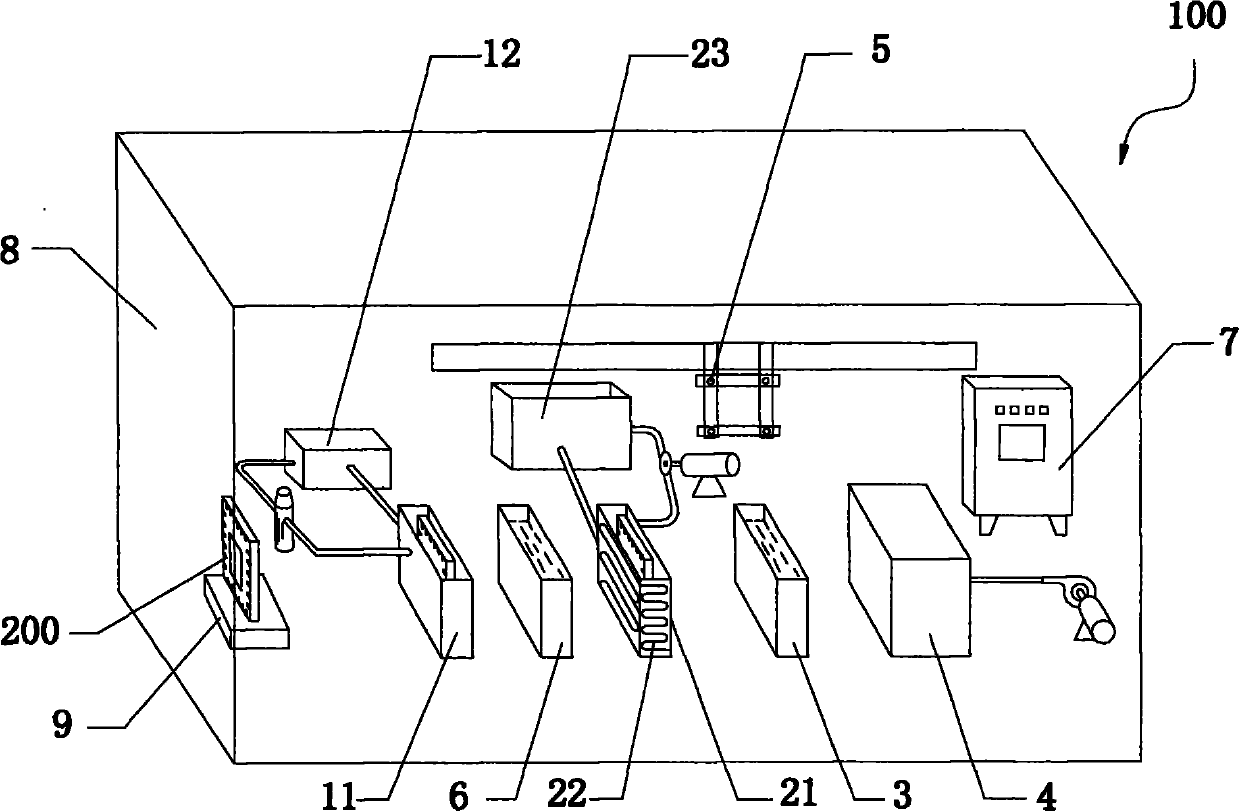

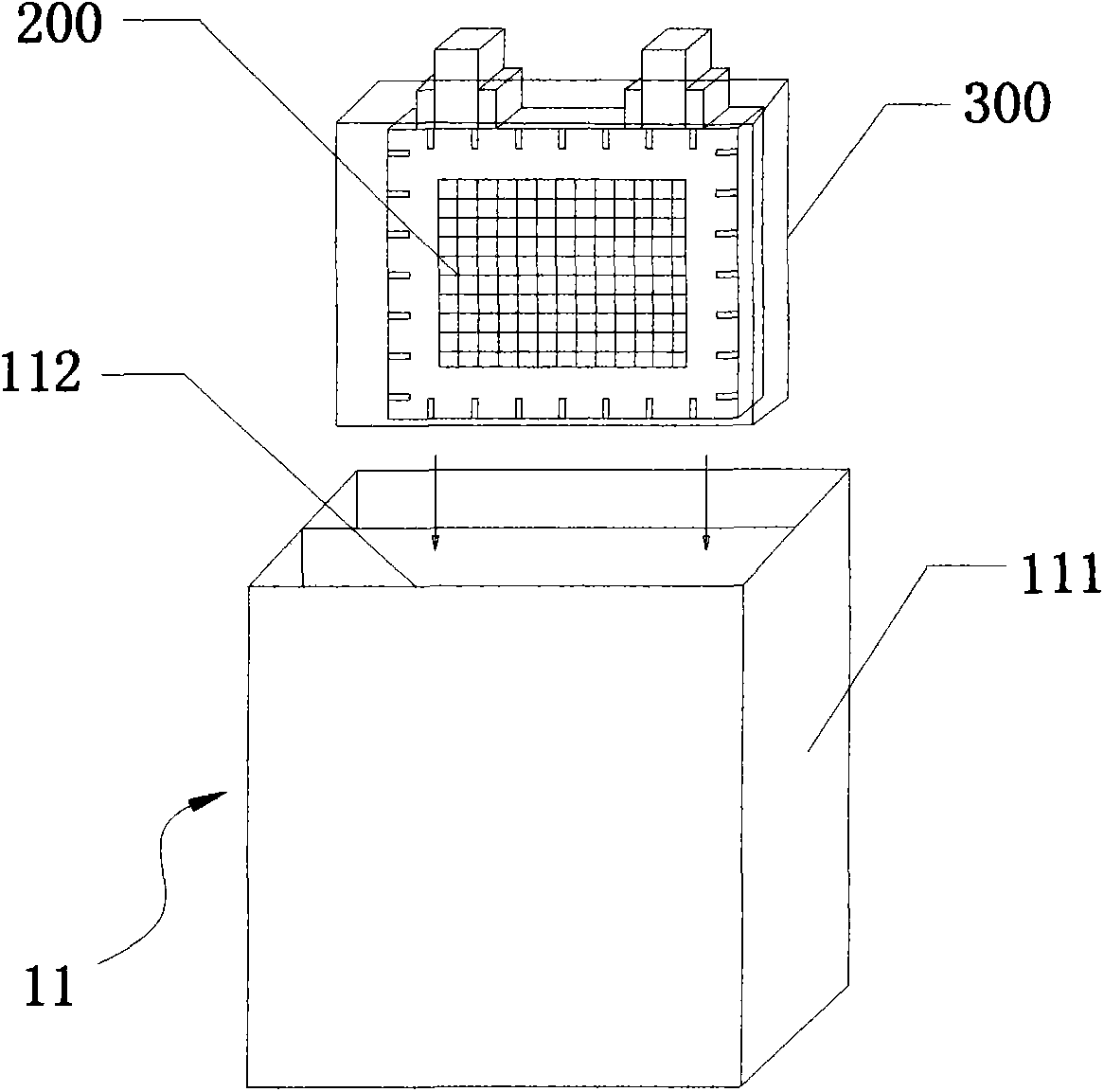

[0024] refer to Figure 1 ~ Figure 3 As shown, this embodiment provides a mask cleaning system 100 , which is mainly used for cleaning organic luminescent material residues attached to the surface of the mask 200 and particle impurities at the evaporation holes provided on the mask 200 . The mask plate cleaning system 100 includes a first cleaning device 1, a second cleaning device 2, a first rinsing device 3 and a drying device 4, wherein the first cleaning device 1 is used to clean the particle impurities at the evaporation holes, and the second The second cleaning device 2 is used for cleaning the organic luminescent material residues on the surface of the mask 200 , the first rinsing device 3 is used for rinsing the mask 200 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com