Preparation method for fiber having functions of thermal storage and temperature regulation

A heat storage and temperature regulation, fiber technology, applied in the chemical characteristics of fibers, rayon manufacturing, single-component polyester rayon, etc. , The effect of excellent heat storage and temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

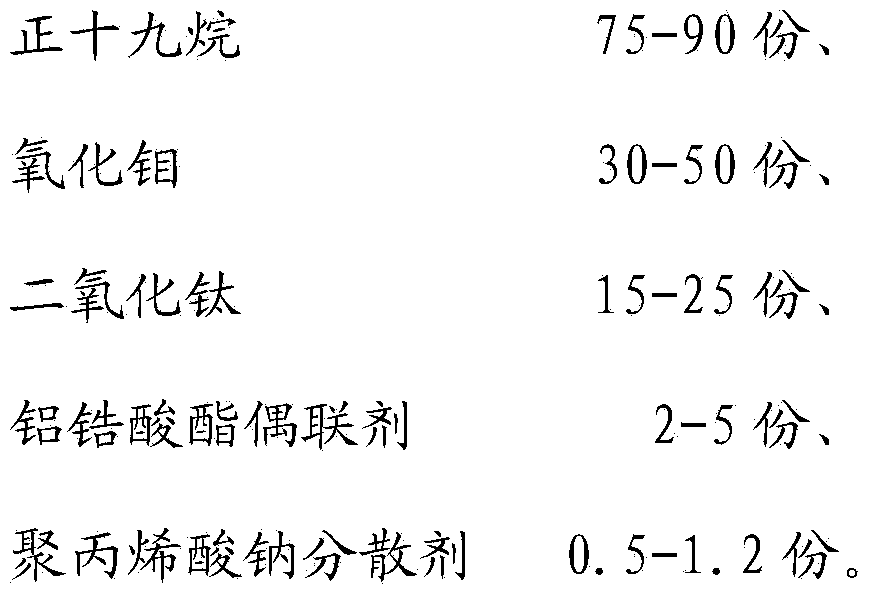

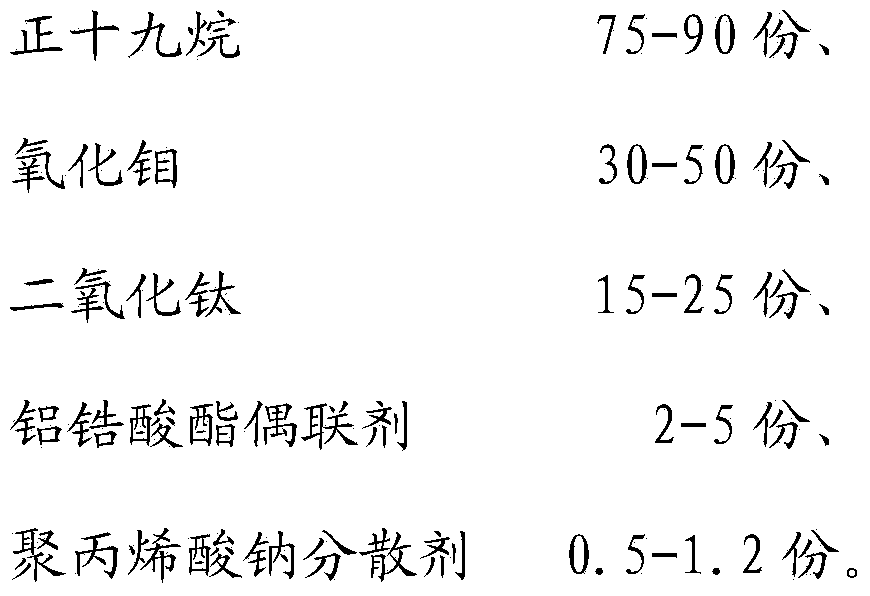

[0019] Preparation of heat storage and temperature regulating agent:

[0020] Mix 75 grams of n-nonadecane, 50 grams of molybdenum oxide and 25 grams of titanium dioxide, then slowly add 5 grams of aluminum zirconate coupling agent and 1.2 grams of sodium polyacrylate dispersant at the same time, the feeding is completed within 1 hour, and continue to mix for 20 minutes .

[0021] Production of heat storage and temperature regulating polyester fiber:

[0022] Blend and dry the heat storage and temperature regulating agent with polyethylene, enter the screw extruder to melt, blend and extrude, and granulate to obtain the heat storage and temperature regulating masterbatch. The heat storage and temperature regulating agent in the heat storage and temperature regulating masterbatch accounts for 5wt %;

[0023] After blending the heat-storage and temperature-regulating masterbatch and polyester fiber chips at a mass ratio of 1:10, the heat-storing and temperature-regulating poly...

Embodiment 2

[0028] Preparation of heat storage and temperature regulating agent:

[0029] Mix 90 grams of n-nonadecane, 30 grams of molybdenum oxide and 15 grams of titanium dioxide, then slowly add 2 grams of aluminum zirconate coupling agent and 0.5 grams of sodium polyacrylate dispersant at the same time, the feeding is completed within 2 hours, and continue to mix for 30 minutes .

[0030] Production of heat storage and temperature regulating acrylic fiber:

[0031] Blend and dry the heat storage and temperature regulating agent with polyethylene, enter the screw extruder to melt, blend and extrude, and granulate to obtain the heat storage and temperature regulating masterbatch. The heat storage and temperature regulating agent in the heat storage and temperature regulating masterbatch accounts for 20wt %;

[0032] After blending the heat-storage and temperature-regulating masterbatch and acrylic fiber chips at a mass ratio of 1:20, the heat-storing and temperature-regulating acryli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com