Ultra-thin wearing course and construction method thereof

A wear layer, ultra-thin technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of insufficient bonding strength, peeling of mixtures, etc., and achieve high softening point, good aging ductility, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

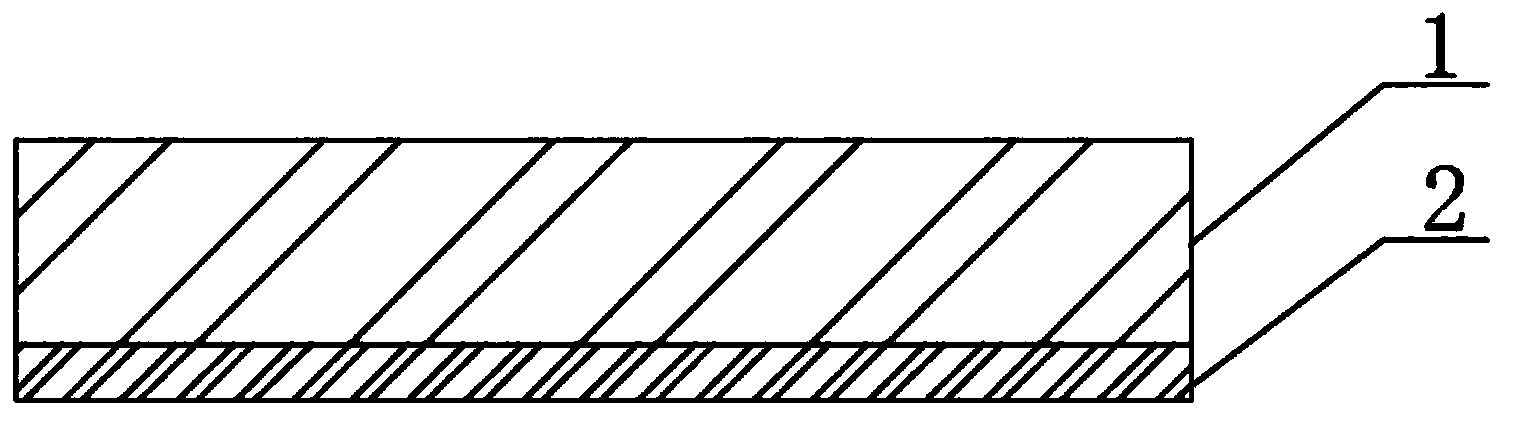

[0033] When the design porosity of the mixture in the ultra-thin composite modified asphalt wear layer 1 is 3%-6% discontinuous dense gradation, the SBS and rubber powder composite modified asphalt contains 80.7-87.8 parts of AH-70# matrix asphalt, 2-3 parts of SBS modifier, 10-14 parts of rubber powder, 0-2 parts of compatibilizer, 0.2-0.3 parts of stabilizer, forming low SBS and high rubber powder composite modified asphalt, composite modified asphalt is modified by rubber powder The properties of composite modified asphalt are better than rubber powder modification, and the high temperature stability of composite modified asphalt ultra-thin wear layer 1 is superior.

[0034] Raw material preparation:

[0035] (1) Preparation of bonding layer 2 materials: take 18 parts of 60 mesh rubber powder, 82 parts of base asphalt, and 0.25 parts of stabilizer. The base asphalt is heated to 180°C, the rubber powder is poured into the base asphalt and stirred for 2.5 hours, and then the stab...

Embodiment 2

[0053] When the designed porosity of the composite modified asphalt ultra-thin wear layer 1 is a discontinuous half-open gradation with a porosity greater than 10%, the SBS and rubber powder composite modified asphalt contains 91.7-95.3 parts of AH-70# matrix asphalt, SBS3.5 -4 parts, rubber powder 1-4 parts, stabilizer 0.2-0.3 parts, to form high SBS low rubber powder modified asphalt, SBS and rubber powder composite modified asphalt is SBS modified asphalt (ID) properties. High SBS and low content rubber powder can also be used in discontinuous dense gradation mixture (SMA).

[0054] Raw material preparation:

[0055] (1) The adhesive layer 2 adopts the rubber powder modified asphalt of Example 1.

[0056] (2) Preparation of materials for composite modified asphalt ultra-thin wear layer 1. The composite modified asphalt ultra-thin wear layer 1 includes 4.9 parts of SBS and rubber powder composite modified asphalt, 100 parts of aggregate, and 3 parts of filler, wherein the aggrega...

Embodiment 3

[0067] The composite modified asphalt ultra-thin wear layer 1 has a discontinuous dense gradation with a design porosity of 3%-6%. The SBS and rubber powder composite modified asphalt contains 93.8 parts of AH-70# base asphalt, 4 parts of linear SBS modifier, 2 parts of rubber powder, and 0.2 parts of stabilizer. The base asphalt is divided into 42 parts of group A and group B 25.9 copies, group C 25.9 copies. Others were carried out according to Example 2 to prepare SBS and rubber powder composite modified asphalt.

[0068] Raw material preparation:

[0069] (1) The adhesive layer adopts the rubber powder modified asphalt of Example 1.

[0070] (2) Preparation of materials for composite modified asphalt ultra-thin wear layer 1. The composite modified asphalt ultra-thin wear layer 1 includes 5.9 parts of SBS and rubber powder composite modified asphalt, 100 parts of aggregates, 10 parts of fillers, and 0.3 parts of fibers. The aggregate includes 85 parts of coarse aggregate and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extensibility | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com