Prefabricated panel capable of effectively preventing cracking and cracking-preventing construction method thereof

A technology of prefabricated wall panels and construction methods, applied in the processing of building materials, building components, buildings, etc., can solve the problems of difficult to solve cracking, complicated construction, no compensation for deformation and energy storage, etc., and is convenient for factory mass production and construction. Simple process and the effect of reducing the probability of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

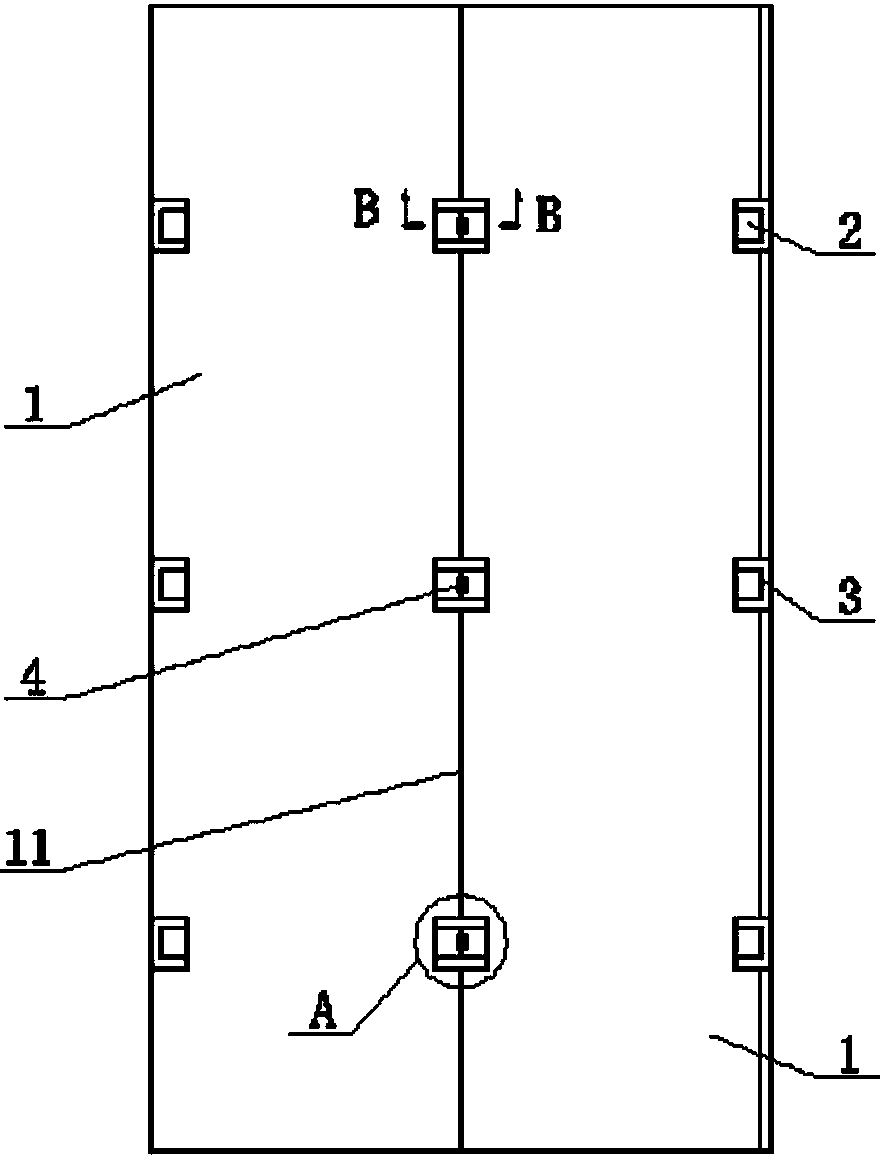

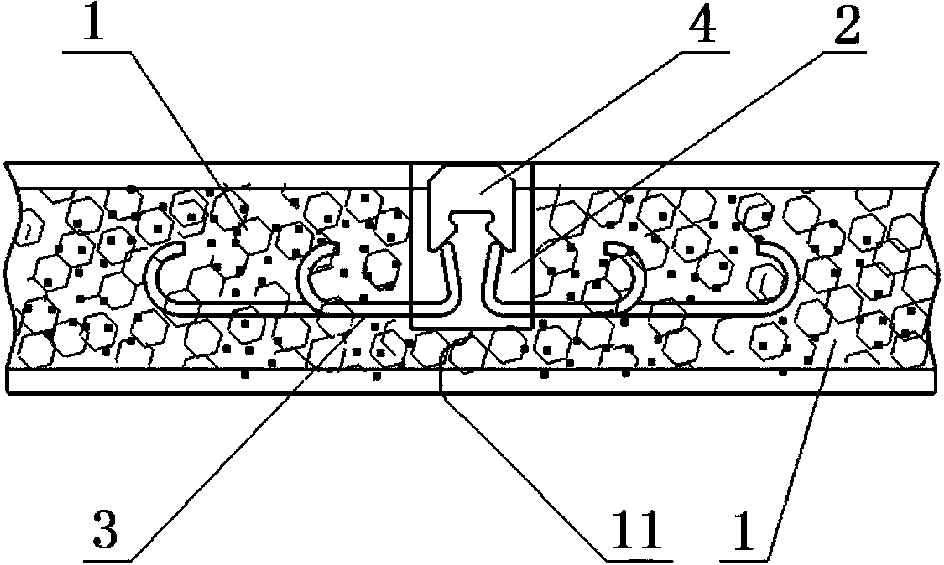

Embodiment 1

[0043] Take two prefabricated wall panels with convex and concave tenons that can effectively prevent cracking, match the convex and concave tenon joints 11 of the left and right two wall panels and make the corresponding windows 2 face each other to complete the assembly of the wall panels; then use wire cutters or crowbars After the elastic deformation section 32 of the tension spring 3 of the prefabricated wall panel is changed from an acute angle to a right angle by means of external force, the locking piece 4 is pressed in so that the locking section 43 and the locking section 33 of the tension spring 3 are elastically fastened; The window 2 and / or the tenon and tenon joint 11 after the spring is locked are filled with glass wool, and then the window 2 and the tenon and tenon joint 11 are painted with common leveling agent, and finally the prefabricated wallboard joint is completed by scraping. construction.

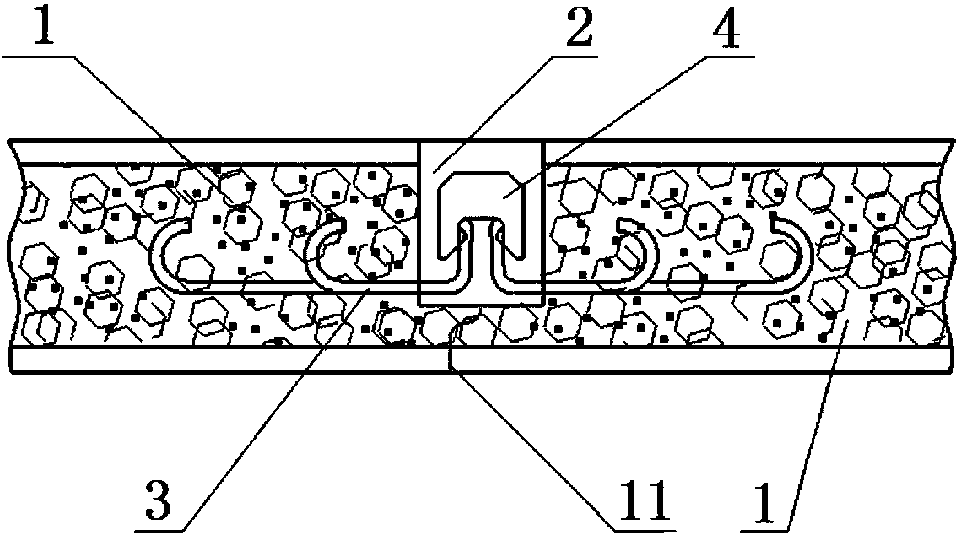

Embodiment 2

[0045] Take two prefabricated wall panels whose flat ends can effectively prevent cracking, align the end faces of the left and right two wall panels and make the corresponding windows 2 face each other to complete the assembly of the wall panels; then use wire cutters or crowbars to make the prefabricated wall panels After the elastic deformation section 32 of the tension spring 3 changes from an acute angle to a right angle, tighten the locking section 33 corresponding to the left and right tension spring 3 with iron wire to achieve the purpose of locking the tension spring 3; after the spring is locked, the window 2 and / or Or fill the mixture of rock wool and styrofoam in the gaps of the butt joint ends, then use common leveling agent to paint the window 2 and the gaps of the butt joint ends, and finally scrape white to complete the construction of the prefabricated wallboard joints.

Embodiment 3

[0047] Take two prefabricated wall panels with convex and concave tenons that can effectively prevent cracking, match the convex and concave tenon joints 11 of the left and right two wall panels and make the corresponding windows 2 face each other to complete the assembly of the wall panels; then use wire cutters or crowbars After the elastic deformation section 32 of the tension spring 3 of the prefabricated wallboard is changed from an acute angle to a right angle by means of external force, the locking section 33 of the left and right corresponding tension spring 3 is fixedly connected by electric welding to achieve the purpose of locking the tension spring 3; Fill the locked window 2 and / or the tenon-and-tenon joint 11 with an appropriate amount of common anti-crack mortar, then use common leveling agent to paint the window 2 and the tenon-and-tenon joint 11, and finally scrape white to complete the prefabricated wallboard Construction of seams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com