Method for optimizing microbial oil displacement site injection process parameters

A technology of process parameter optimization and microbial flooding, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problem of low accuracy and reliability of on-site injection process parameters, undetermined parameter value range, There are no problems such as theoretical basis, and it achieves the effect of high reliability and accuracy, simple steps, and improved test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Taking Block A of an oil production plant in Shengli Oilfield as an example, Block A is a hydrophilic unconsolidated sandstone reservoir with high permeability, high saturation, medium-high viscosity, and fluvial deposits, with a burial depth of 1173m-1230m, a reservoir temperature of 69°C, and a pressure of 10MPa , coefficient of variation of permeability 0.538, porosity 33%, air permeability 1.5μm 2 ~2.5μm 2 , the oil-bearing area of the test area is 0.86km 2 , effective thickness 10.4m, geological reserves 164.9×10 4 t, 14 oil wells, 8 water wells, utilize the method of the present invention to carry out microbial flooding site injection process parameters optimization, determine the best site injection process parameters, the concrete steps are as follows:

[0023] (1) On-site injection process parameters screening

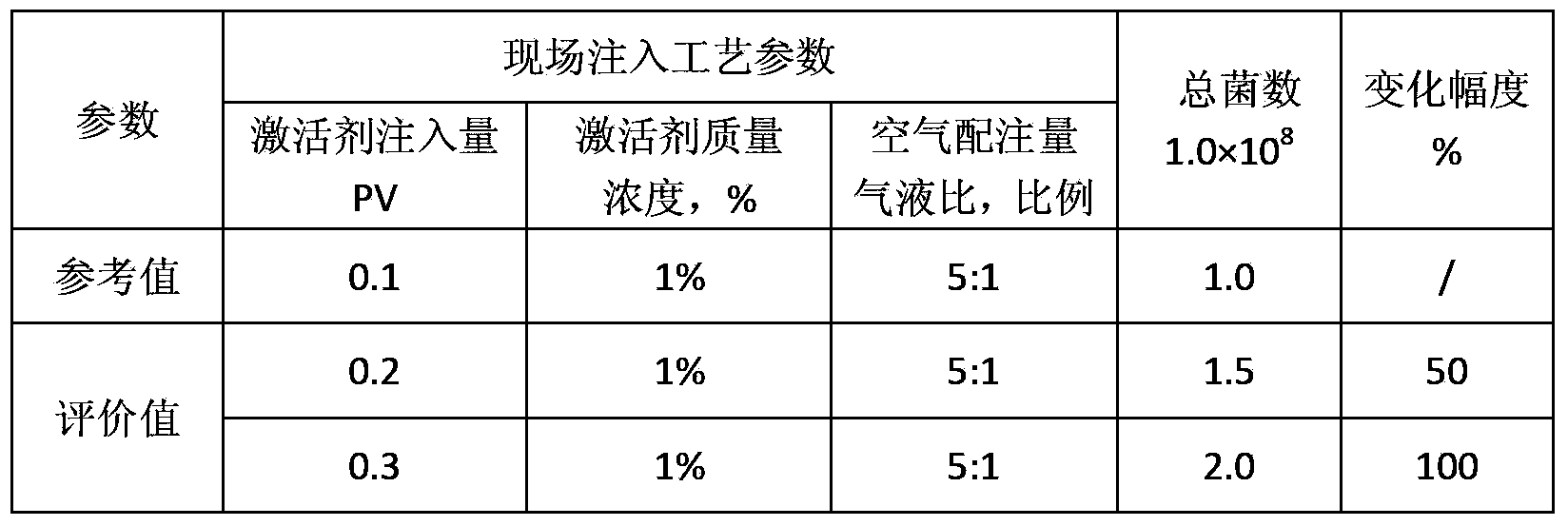

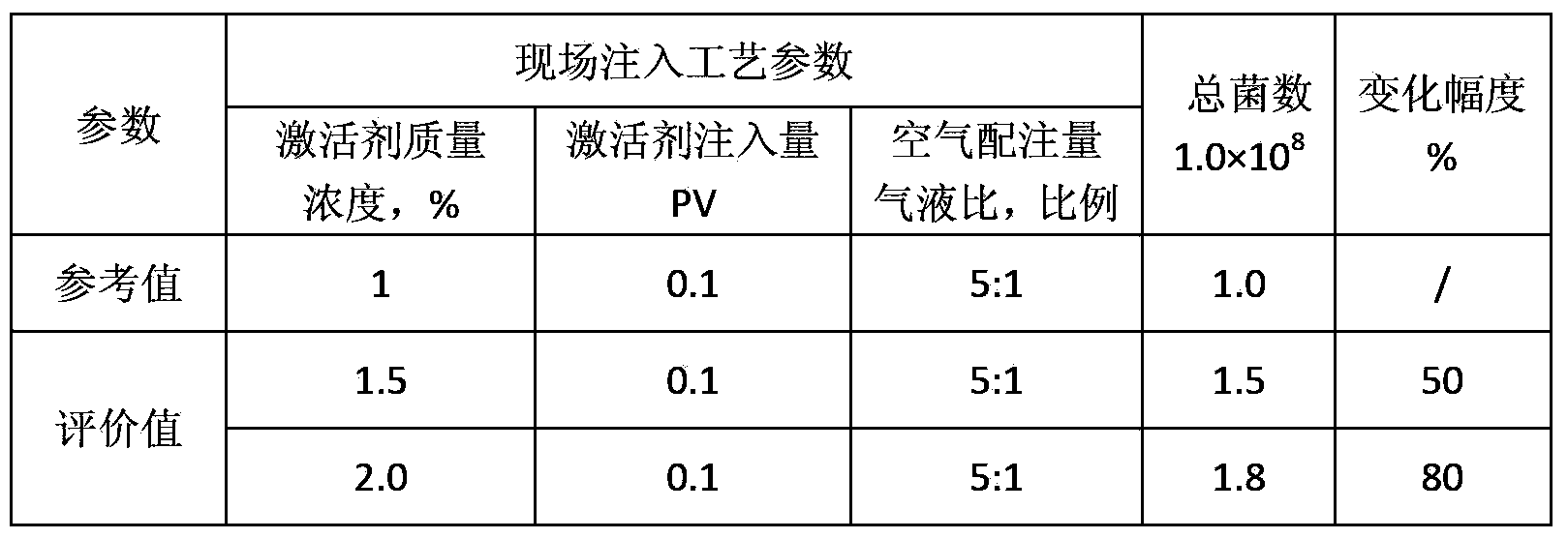

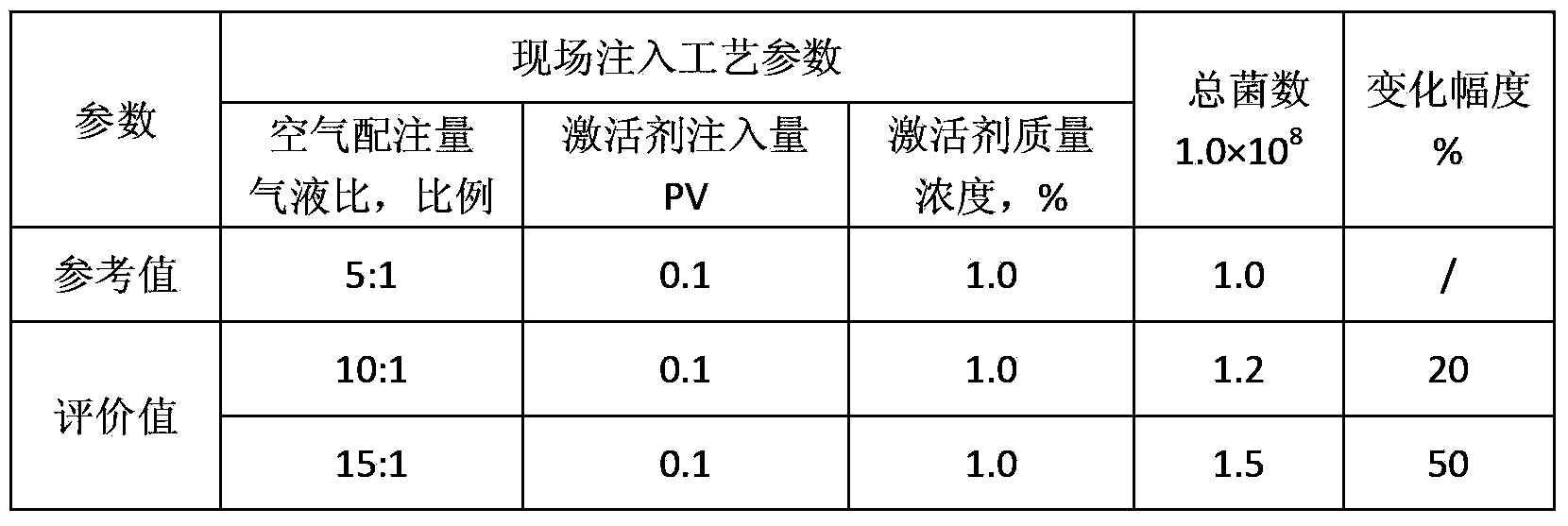

[0024] The process parameters selected for block A are activator concentration, activator injection volume, and air injection volume. The indoor s...

Embodiment 2

[0052] Taking Block F of an oil production plant in Shengli Oilfield as an example, Block F is a water-loving reservoir of unconsolidated sandstone deposited in fluvial facies with high permeability, high saturation, medium-high viscosity, burial depth of 1598m-1965m, reservoir temperature of 85°C and pressure of 9.5°C. MPa, permeability coefficient of variation 0.635, porosity 35.3%, air permeability 1.8μm 2 ~3.5μm 2 , the oil-bearing area of the test area is 1.96km 2 , effective thickness 20.5m, geological reserves 563.8×10 4 t. 12 oil wells, 6 water wells, utilize the method of the present invention to carry out microbial flooding field injection process parameter optimization, determine the best field injection process parameter, concrete steps are as follows:

[0053] (1) On-site injection process parameters screening

[0054] The process parameters selected for block F are activator concentration, activator injection volume, activator injection method and air injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com