Inclined gradually varied porous end surface non-contact type mechanical sealing structure

A mechanical seal, non-contact technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problem of strong pressure resistance and anti-interference ability, insufficient pressure resistance and anti-interference ability, good end surface lubrication effect, etc. problems, achieve good wear resistance and lubricating ability, avoid high frictional heat generation, and have the effect of strong dynamic pressure opening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

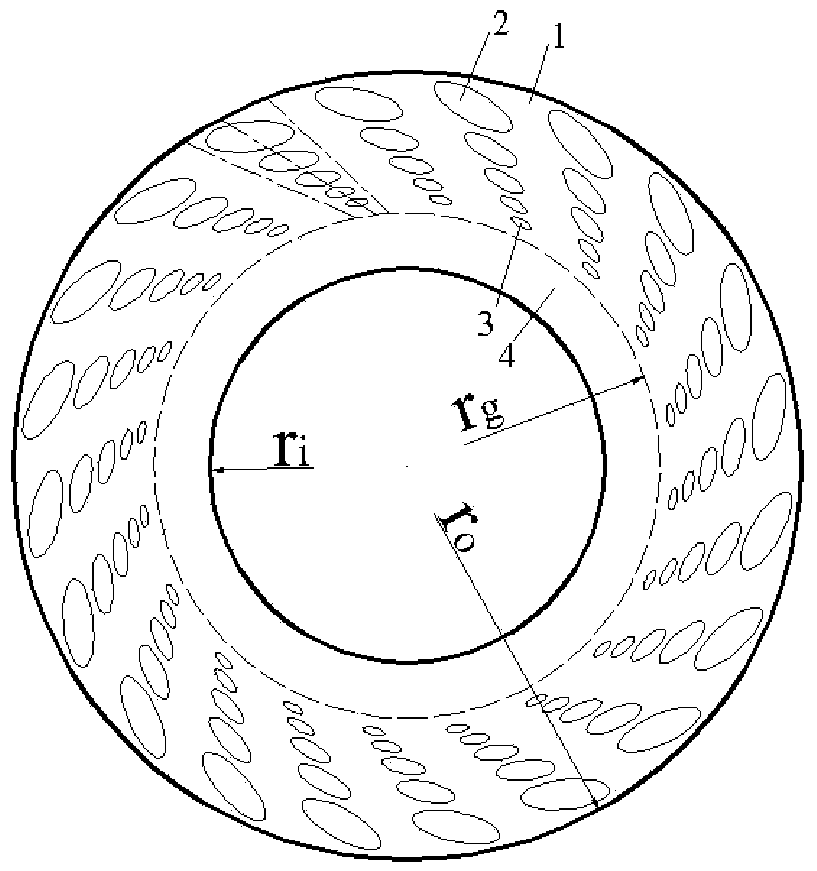

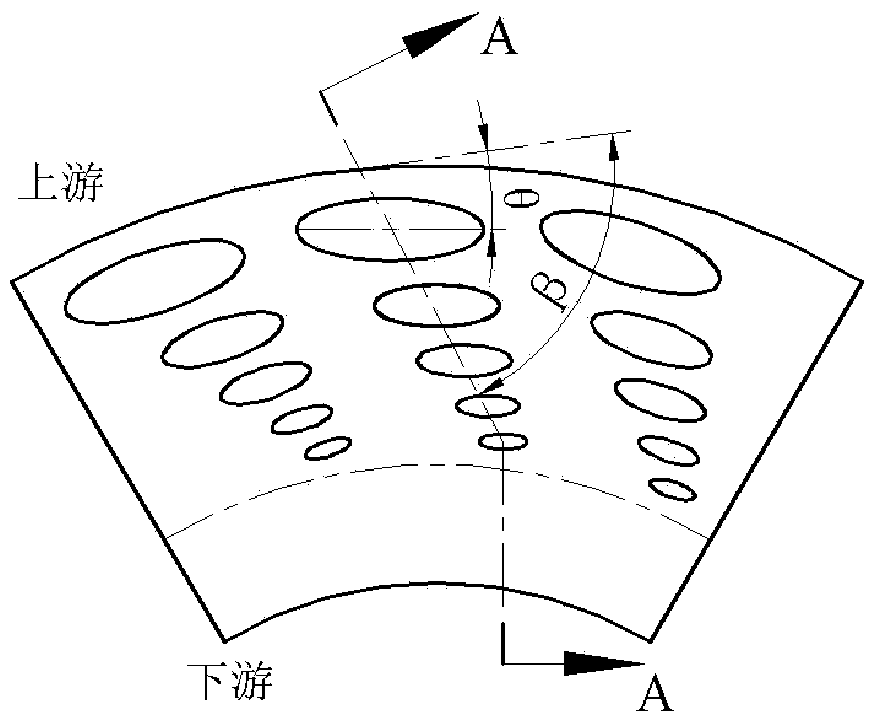

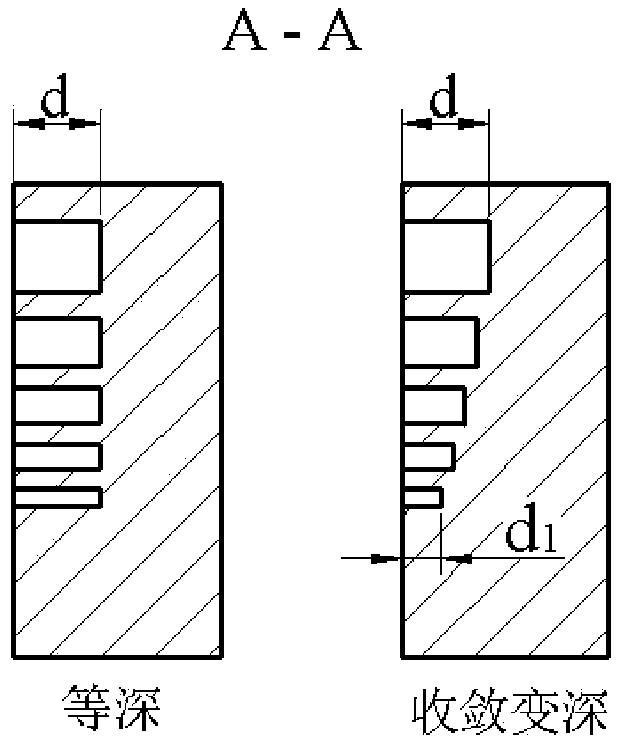

[0033] see figure 1 , 2 , 3:

[0034] Non-contact mechanical seal structure with inclined and gradual porous end face, which includes a moving ring and a static ring of the mechanical seal. The side is the low-pressure side, that is, the downstream side, and it is characterized in that: the end surface of at least one sealing ring in the moving ring or the static ring is provided with inclined gradual holes symmetrically distributed according to the center of rotation, forming a ring belt of gradual holes; The queues are arranged in an inclined straight line with an inclination angle to the diameter of the end face, and the inclination angles of each queue are equal; the gradual change holes in the queue gradually decrease from the high pressure side, that is, the upstream to the low pressure side, that is, the downstream aperture; they are located at the same radius The size of the tapered hole on the top is the same; the upstream and downstream of the end face of the seali...

Embodiment 2

[0043] see Figure 4 : The gradient hole shape can be one of the following: circle, triangle, square, ellipse, rhombus, rectangle or hexagon.

[0044] The remaining structures and implementation modes of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0046] see figure 1 , 5 : The gradient ellipse holes themselves have directionality, and can be inclined around the center of each hole, and the inclination angle θ ranges from 0 to 180. In Arrangement 1, the direction of the shear flow and the differential pressure flow are consistent and both point to the downstream side. Under the action of tangential rotational speed shear, the fluid will flow along the long axis of the hole, so that the fluid is continuously accumulated and superimposed in the long axis direction, and is affected by Continuous compression, the pressure gradually increases, thus forming an obvious dynamic pressure opening performance From arrangement 2 to arrangement 6, as the number of pumping holes in the upstream of the low pressure side gradually increases, so that the fluid leaking from the high pressure side to the low pressure side The return to the high-pressure side is more obvious, so that the leakage rate gradually decreases. Among them, the ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com