Carbon-based composite material artificial bone repair material and preparation method thereof

A carbon-based composite material and carbon composite material technology, applied in medical science, tissue regeneration, prosthesis and other directions, can solve the problems of aging of polymer materials, easy metal wear, easy fatigue, etc., to ensure elastic modulus and avoid friction. Abrasion, the effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Multi-layer carbon fiber cloth (6k, 160g / m 2 ) and carbon fiber mesh (60g / m 2 ) cross-laminated needle-punched compound to the desired thickness, to obtain a bulk density of 0.4g / cm 3 carbon fiber prefabricated body;

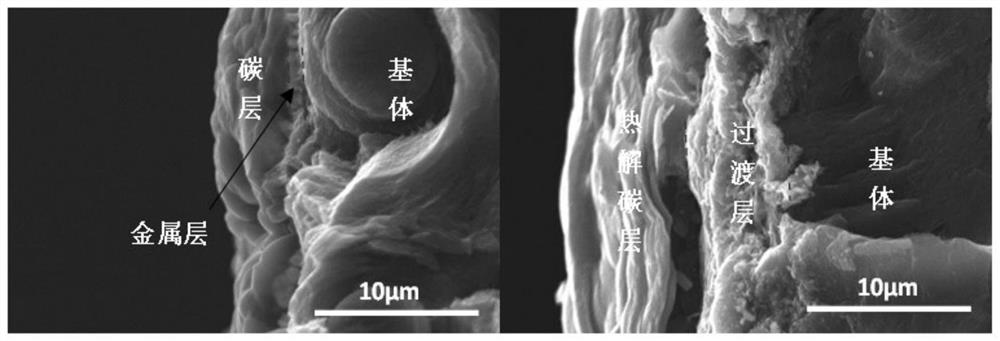

[0043] 2) Densifying the carbon fiber prefabricated body with matrix carbon,

[0044] The process of densifying matrix carbon is chemical vapor deposition: the chemical vapor deposition process conditions: put the carbon fiber prefabricated body into the deposition furnace, and at a temperature of 1100 ° C, pass through a carbon-containing gas source (methane and hydrogen 1:0.5) for deposition , to obtain a porous carbon-based composite blank with a porosity of about 50%;

[0045] 3) The artificial bone defect filling model designed based on the medical imaging data CT processes the sheet blank into a profiling artificial bone body (including preset holes with a diameter of 1.0 mm), specifically as follows figure 1 shape;

[0046] 4) sequentially ...

Embodiment 2

[0055] 1) Multi-layer carbon fiber cloth (1k, 60g / m 2 ) and carbon fiber mesh (40g / m 2 ) cross-laminated needle-punched compound to the desired thickness, to obtain a bulk density of 0.4g / cm 3 It is a carbon fiber prefabricated body;

[0056] 2) The process of densifying the carbon fiber prefabricated matrix carbon and densifying the matrix carbon is an impregnation-cracking process: the carbon fiber prefabricated body undergoes vacuum pressure impregnation, curing treatment, cracking, and other densification processes with phenolic resin. The specific process conditions: impregnation pressure The temperature is 2.0MPa, the impregnation time is 6h; the curing temperature is 200°C, the curing time is 20h; the cracking temperature is 1000°C, normal pressure, the time is 10h, and the porous carbon-based composite material blank with a porosity of about 55% is obtained;

[0057] 3) Put the obtained green body into a high-temperature furnace, and heat it under vacuum or protectiv...

Embodiment 3

[0068] 1) Multi-layer single carbon fiber mesh (60g / m 2 ) laminated needle-punched composite to the desired thickness, to obtain a bulk density of 0.2g / cm 3 It is a carbon fiber prefabricated body;

[0069] 2) The carbon fiber prefabricated body is densified matrix carbon, and the process of densifying matrix carbon is chemical vapor deposition first, and then impregnation-cracking:

[0070] The chemical vapor deposition process conditions: put the carbon fiber prefabricated body into a deposition furnace, at a temperature of 1100° C., feed a carbon-containing gas source (methane and hydrogen 1:0.5), and deposit for 10 hours.

[0071] The impregnation-cracking process includes phenolic resin vacuum pressure impregnation, curing treatment, cracking, and other densification processes. The process conditions: the impregnation pressure is 2.0 MPa, the impregnation time is 6 hours; the curing temperature is 200 ° C, and the curing time is 20 hours; The pyrolysis temperature is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com