Method for drying industrial materials by high-temperature heat pump

A heat pump drying and high temperature heat pump technology, applied in drying solid materials, heating to dry solid materials, drying and other directions, can solve the problems of restricting production efficiency, difficult to control heating temperature, long heating time, etc., to achieve rapid heating and The effect of flow speed, improved quality and stability, and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

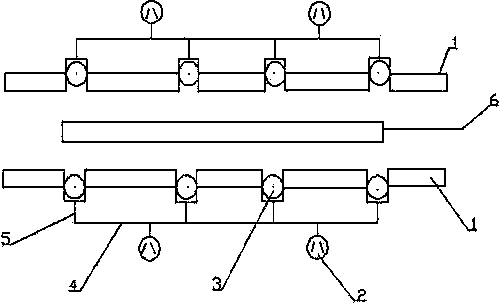

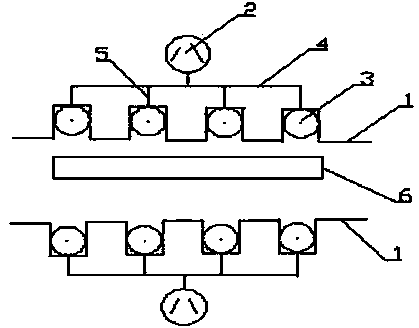

[0025] A method for drying industrial materials with a high-temperature heat pump. The equipment used includes: a kiln wall 1, a heat pump unit 2, a hot air blower 3, a heat collecting pipe 4, and a heat distribution pipe 5. A tunnel-type drying kiln for continuous drying, with doors at both ends, a dehumidification device on the drying kiln, and a temperature and humidity sensor and a signal acquisition and control system inside the drying kiln.

[0026] Such as figure 2 As shown, a group of heat pump units 2 are arranged on the outer wall or roof of the drying kiln for controlling the temperature in the drying kiln at 50-90°C. The kiln wall 1 on one side of the drying kiln is provided with multiple heat supply holes and exhaust holes for the heat pump unit 2 to circulate air intake. Multiple heat pump units are arranged in parallel and simultaneously deliver heat sources to the drying kiln to realize central control. There is a one-fin heat exchanger between the compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com