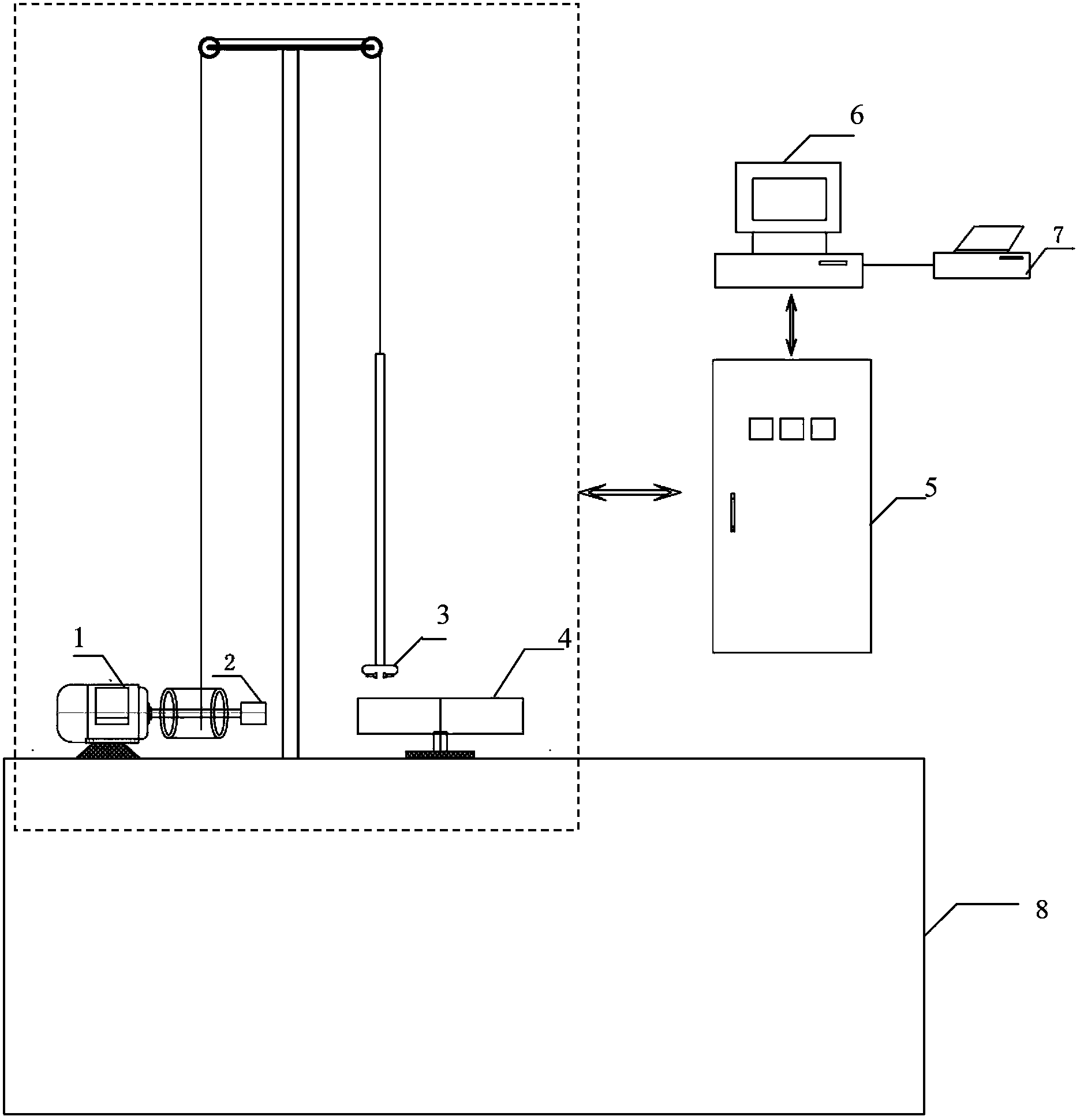

On-line detection method and on-line detection system for supernatant liquid height of settling tank for liquid-solid separation

A detection device and sedimentation tank technology, applied in the cross field, can solve the problems of laborious, time-consuming, and inability to continuously monitor the operation of the sedimentation tank, and achieve the effects of fast detection speed, continuous detection, and easy real-time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

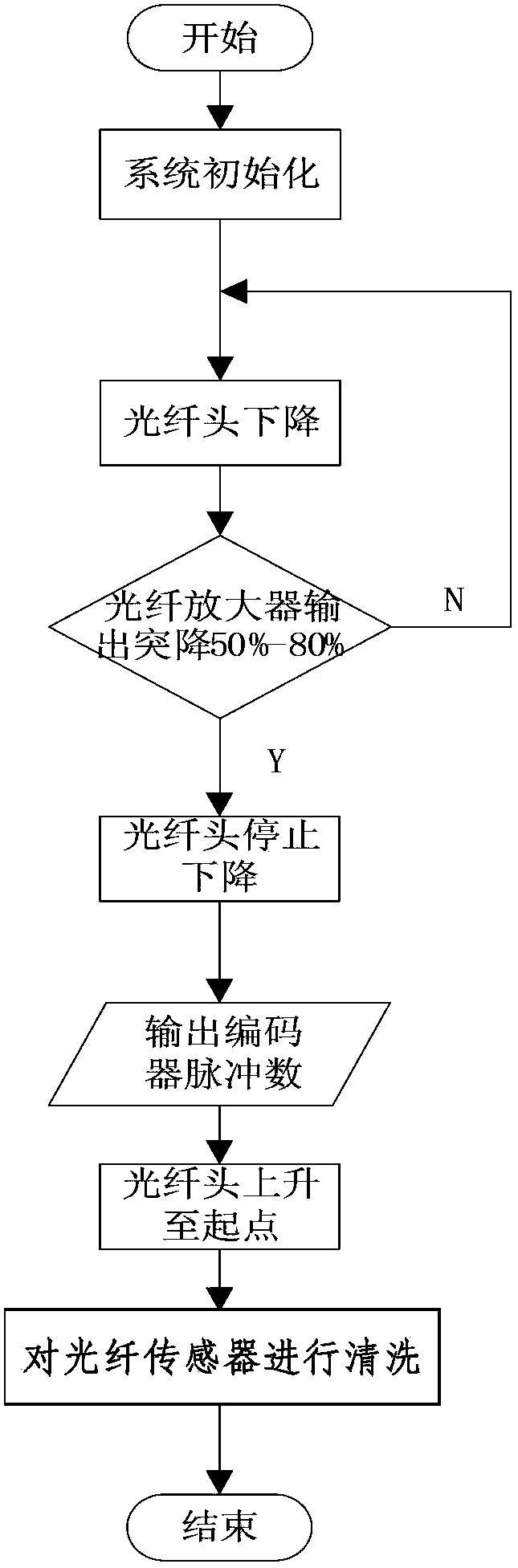

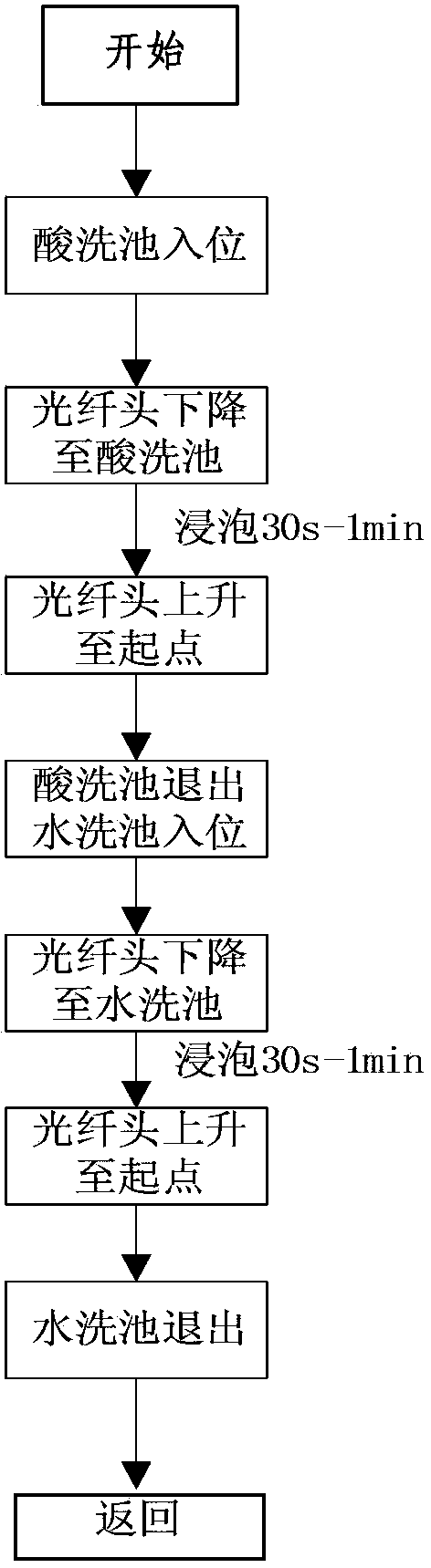

[0058] Embodiment 1: the detection method that adopts the on-line detection device of liquid-solid separation settling tank supernatant liquid layer height, comprises the following steps:

[0059] Step 1. System initialization;

[0060] Step 2, the PLC control system controls the optical fiber head of the optical fiber sensor to descend;

[0061] The PLC control system drives the hoist, sends the optical fiber sensor from the top of the liquid level of the settling tank to the settling tank, and collects the output value of the rotary encoder and the DC voltage signal output Vout of the optical fiber sensor in real time. When the optical fiber sensor in this embodiment just enters the solution in the settling tank, the DC voltage signal output of the optical fiber sensor is Vout=4.96V (the range is 5V), which shows that the solution at the position where the optical fiber sensor is located has better light transmission and is a settling tank. In the clear liquid layer, the PL...

Embodiment 2

[0076] Embodiment 2: the detection method that adopts the on-line detection device of liquid-solid separation settling tank supernatant liquid layer height, comprises the following steps:

[0077] Step 1. System initialization;

[0078] Step 2, the PLC control system controls the optical fiber head of the optical fiber sensor to descend;

[0079] The PLC control system drives the hoist, sends the optical fiber sensor from the top of the liquid level of the settling tank to the settling tank, and collects the output value of the rotary encoder and the DC voltage signal output Vout of the optical fiber sensor in real time. When the optical fiber sensor in this embodiment just enters the solution in the settling tank, the DC voltage signal output Vout of the optical fiber sensor is 4.99V (the range is 5V), which shows that the solution at the position of the optical fiber sensor has better light transmission at this time, and it is a settling tank. In the clear liquid layer, the...

Embodiment 3

[0094] Embodiment 3: the detection method that adopts the on-line detection device of liquid-solid separation settling tank supernatant liquid layer height, comprises the following steps:

[0095] Step 1. System initialization;

[0096] Step 2, the PLC control system controls the optical fiber head of the optical fiber sensor to descend;

[0097] The PLC control system drives the hoist, sends the optical fiber sensor from the top of the liquid level of the settling tank to the settling tank, and collects the output value of the rotary encoder and the DC voltage signal output Vout of the optical fiber sensor in real time. When the optical fiber sensor in this embodiment just enters the solution in the settling tank, the DC voltage signal output of the optical fiber sensor is Vout=4.88V (the range is 5V), which shows that the solution at the position of the optical fiber sensor has better light transmission at this time, and it is a settling tank. In the clear liquid layer, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com