Multi-beam detection device and method based on worm gear lead screw lifting

A technology of worm gear screw and detection device, which is applied in the direction of measurement device, radio wave measurement system, sound wave re-radiation, etc., can solve problems such as poor applicability, shaking of scientific instruments, difficult positioning of instrument support rods, etc., to reduce labor intensity. , The design is simple, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

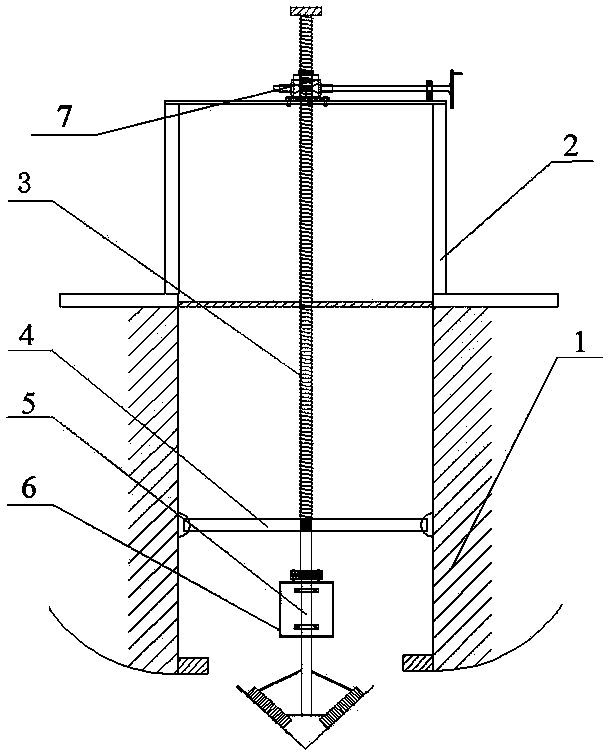

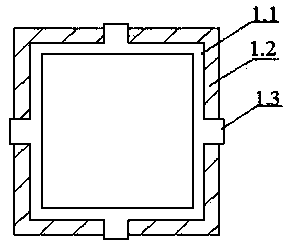

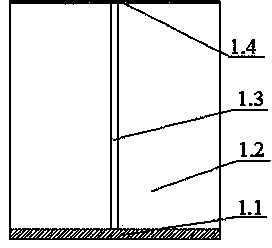

[0040] Refer to attached figure 1 , making a multi-beam detection device based on worm gear screw lifting, which includes: vertical shaft 1, bracket 2, lifting rod 3, lifting car 4, instrument bracket 5, auxiliary instrument warehouse 6 (see attached Figure 10 , 11 ), worm gear screw lifter 7. See attached figure 2 And attached image 3 , the shaft 1 includes a lift car baffle 1.1, a shaft wall 1.2, a lift car track 1.3 and a shaft mouth baffle 1.4; the lift car track 1.3 is on the four sides of the shaft 1; the lift car baffle 1.1 is installed at the bottom of the shaft 1; the shaft mouth baffle 1.4 Installed in shaft 1. See attached Figure 4 And attached Figure 5 , the bracket 2 includes an angle steel tripod 2.1, a top plate 2.2 and a bracket baffle 2.5; the bracket 2 is fixed above the shaft 1 through the angle steel tripod 2.1; the center of the top board 2.2 is provided with a roof lifting rod hole 2.3; the front and rear of the bracket 2 are bracket side door...

Embodiment 2

[0044] Refer to attached figure 1 , make a multi-beam detection device based on the lifting of the worm gear screw, fix the pressure sensor and the surface sound velocity meter to be mounted on the two instrument holes 6.4 in the auxiliary instrument compartment 6, and use the steel hoop 6.2 to assist the instrument compartment 6 It is fixedly installed on the upper end of the vertical bar 5.2 of the instrument support, and the rest is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com