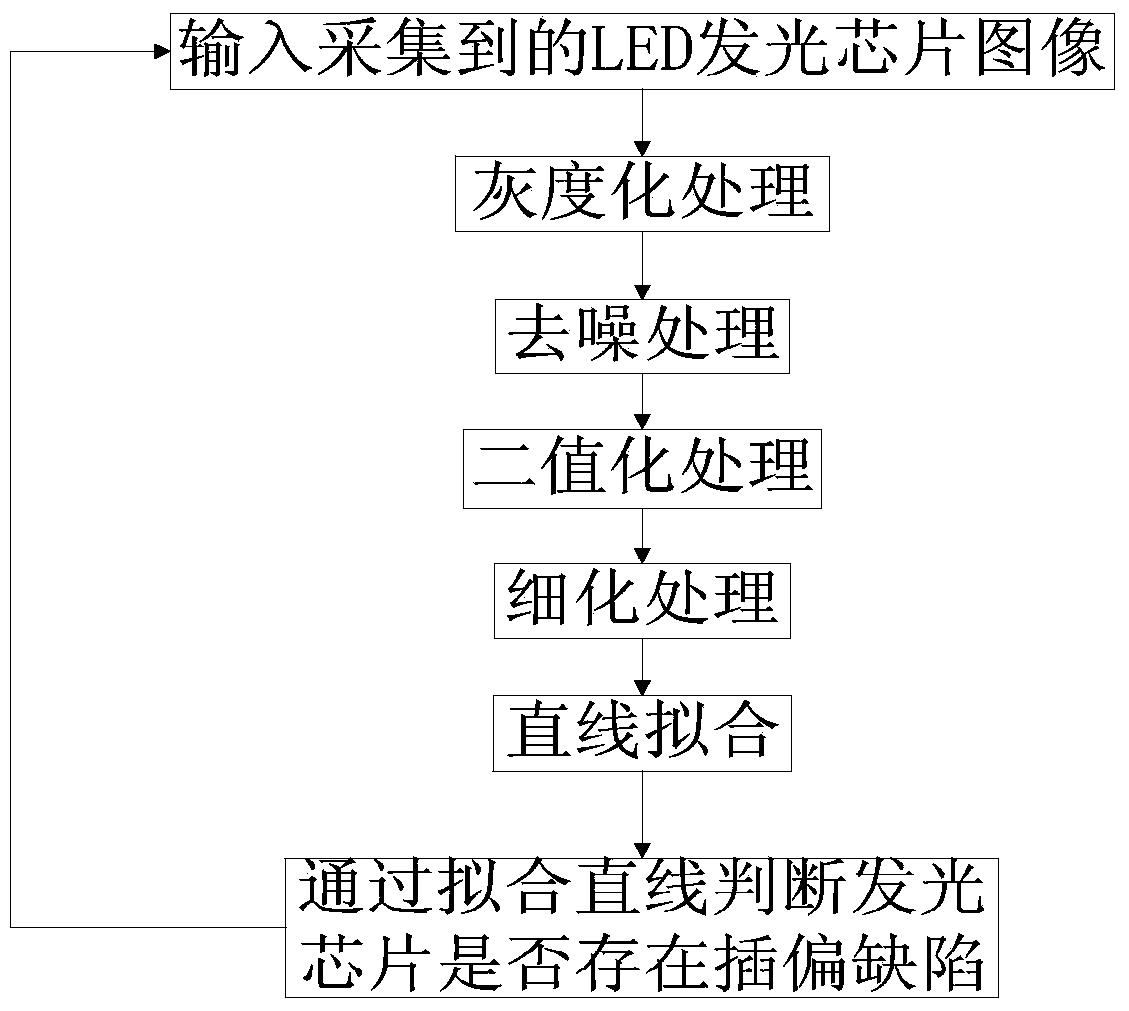

Detecting algorithm for eccentrically-inserting defect of LED luminous chip

A light-emitting chip and detection algorithm technology, applied in computing, image data processing, instruments, etc., can solve problems such as the difficulty of contact sorting, the discreteness of luminous uniformity, and the influence of LED light intensity distribution uniformity, etc., to ensure detection Accuracy, overcoming labor intensity, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

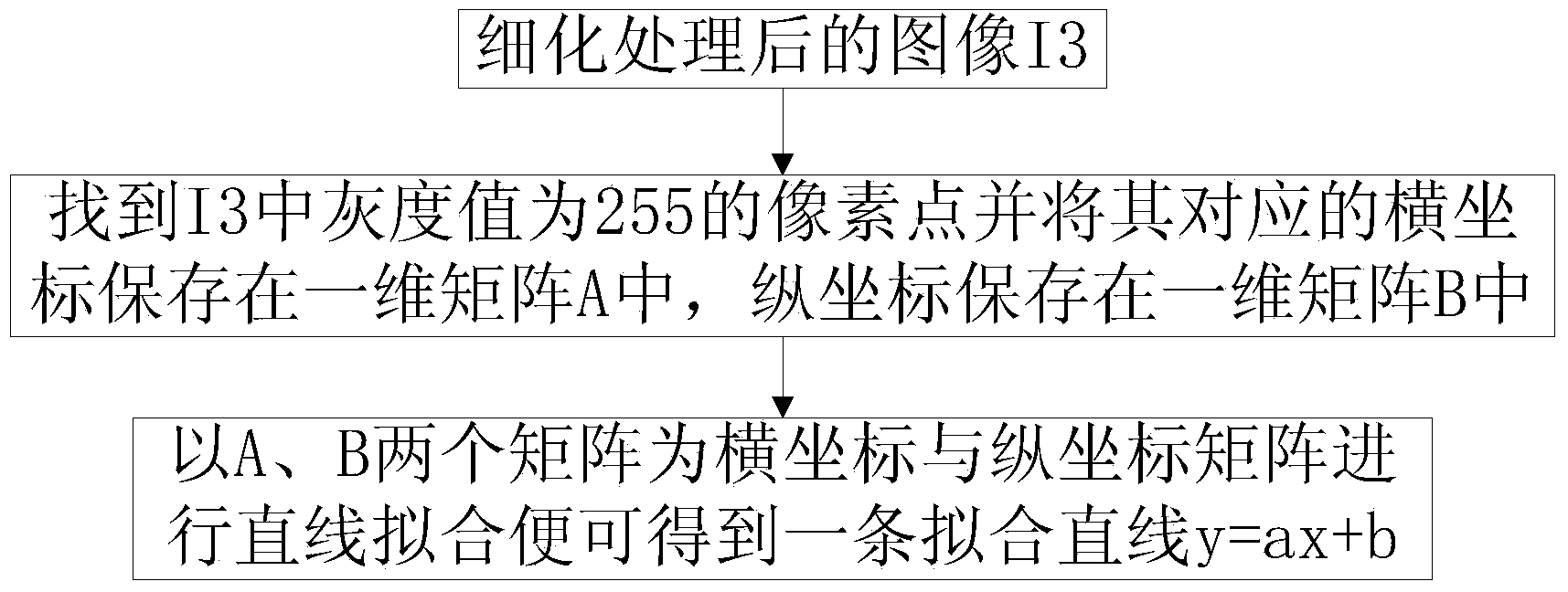

Method used

Image

Examples

Embodiment

[0058] Step 1: collect the color image I of the LED light-emitting chip to be tested, and note that the shooting angle is that the two pins of the light-emitting diode are both vertical and the two pins overlap;

[0059] Step 2: Use the average value method to grayscale the color image I, and then use the median filter method to denoise the grayscaled image. In the median filter method, the size of the filter window is selected as 3*3 to obtain the image I1;

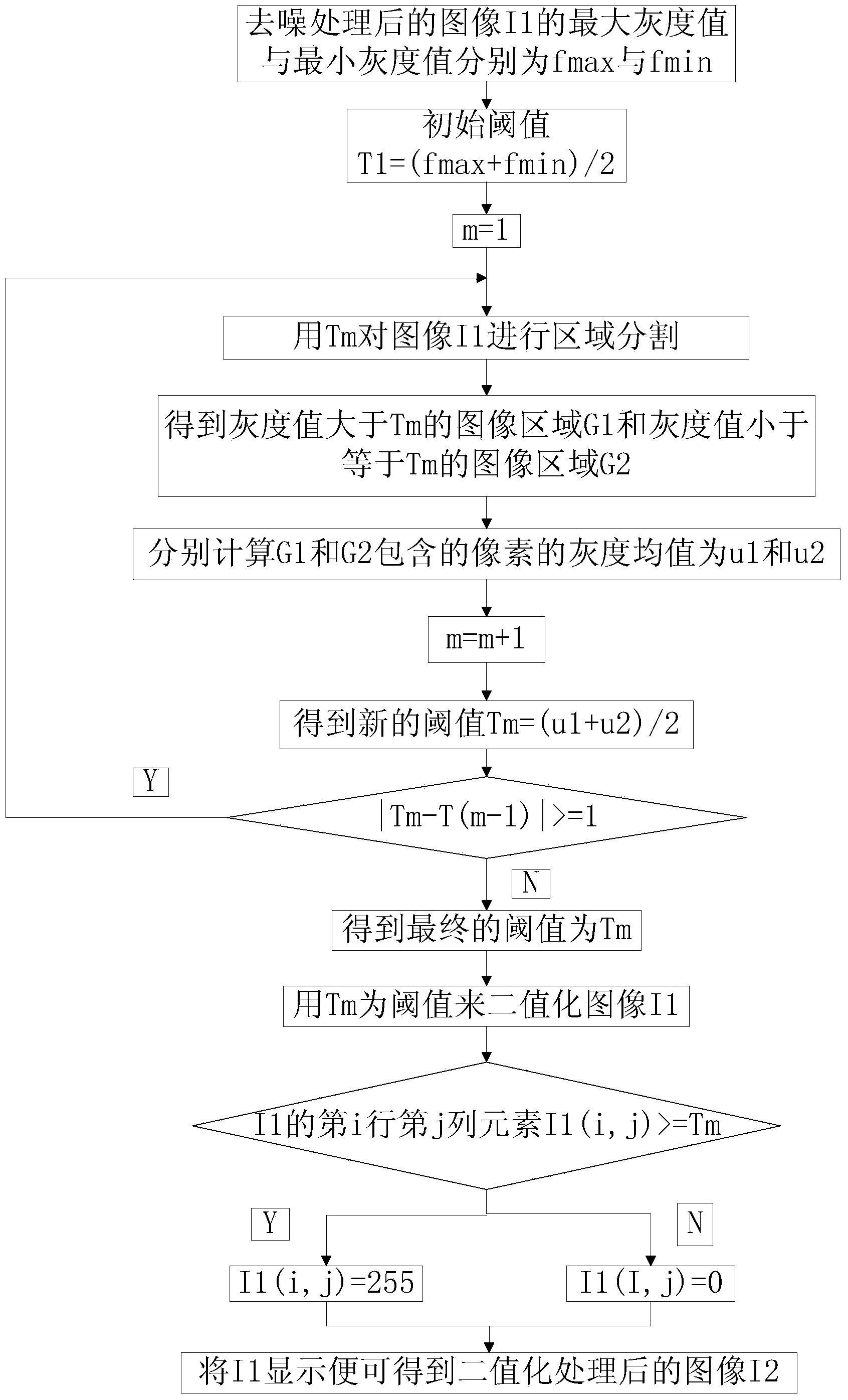

[0060] Step 3: If figure 2 As shown, the image I1 is binarized by iterative threshold segmentation to obtain the binarized image I2; the specific steps are as follows:

[0061] 1) Set the initial segmentation threshold T1=(fmax+fmin) / 2, where fmax and fmin represent the maximum gray value and minimum gray value of image I1 respectively;

[0062] 2) Use the initial segmentation threshold T1 to segment the image I1 to obtain the image area G1 whose gray value is greater than the initial segmentation threshold and the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com