Connector of integral type adaptor cable

An integral, connector technology, applied in the direction of connection, parts and circuits of the connection device, can solve the problems of difficult assembly, small price and cost advantage, unreliable crimping, etc., to ensure stability and reliability, improve Effective power transmission, reducing the effect of microwave signal disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

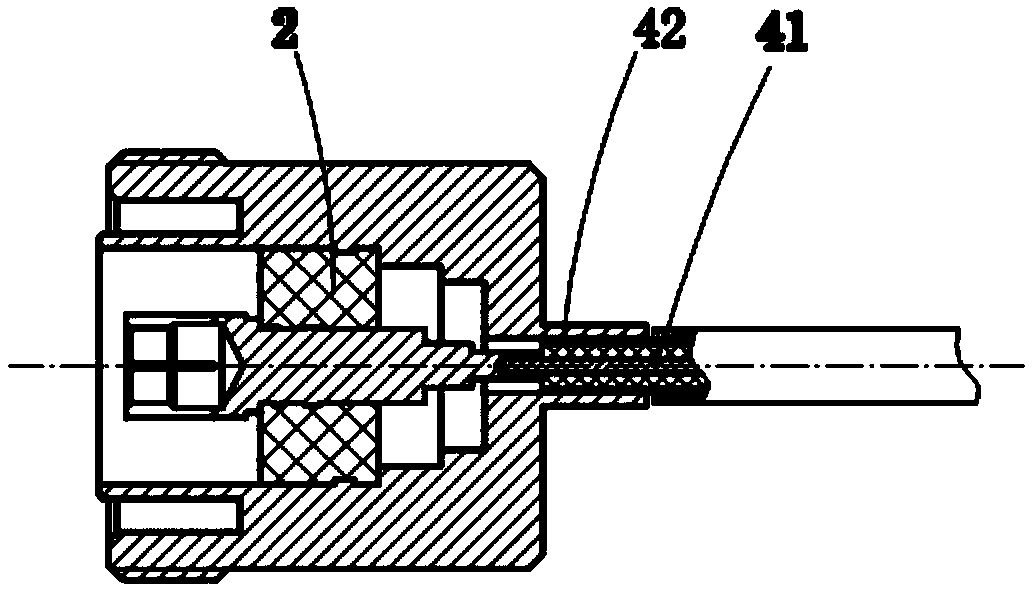

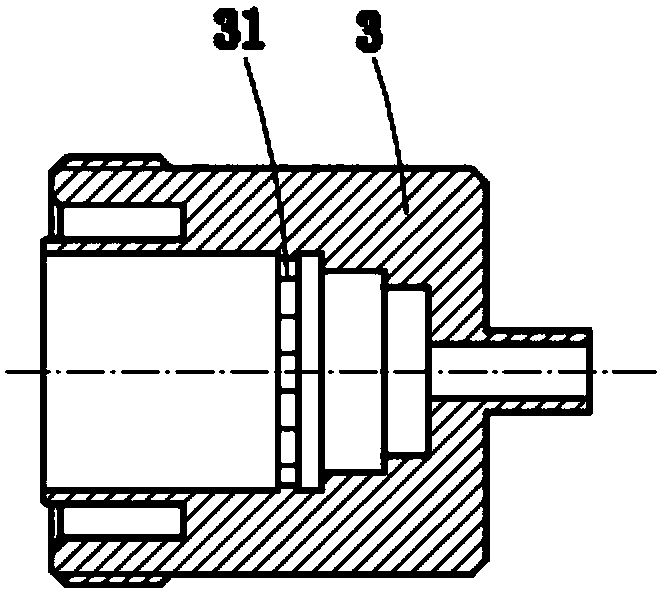

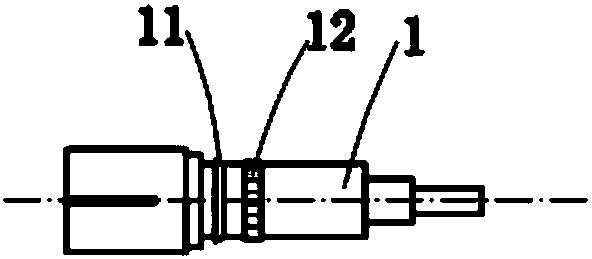

[0015] Example: Combine Figures 1A-1C , the integral type 7 / 16 connector for mating with RG402 cables in this embodiment includes: an inner conductor 1, an insulating medium 2 and an outer conductor 3 that are coaxially distributed from the center in sequence, and the insulating medium 2 is located on the outer circumference and outer surface of the inner conductor 1 Between the walls of the inner cavity of the conductor 3, it plays a role of support and insulation. The tail of the inner conductor 1 is provided with a coaxial inner core welding hole, and the inner core 41 of the radio frequency cable is welded in the inner core welding hole to realize the mechanical erection and electrical performance connection between the inner core 41 of the radio frequency cable and the inner conductor 1; The tail of the outer conductor 3 is in the shape of a stepped shaft, that is, a coaxial shield welded tube is arranged at the tail of the outer conductor 3 , and the inner diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com