Waste iron and steel crushing and furnace material processing integration method and equipment

A technology for scrap iron and steel and furnace charge, which is applied in the field of environmental protection treatment and utilization, can solve the problems of large scrap iron and steel, no sorting, purification system, and complex composition of thin-walled scrap iron and steel, and achieve low equipment manufacturing cost, easy operation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

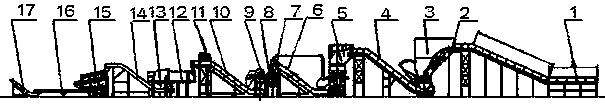

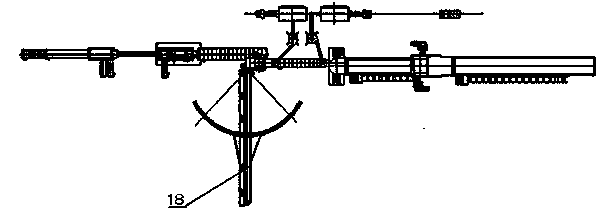

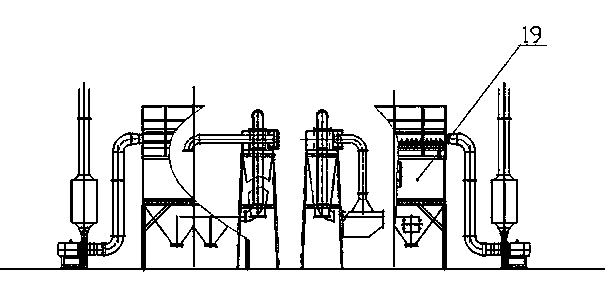

[0034] see figure 1 , figure 2 , image 3 , the scrap iron and steel crushing of the present invention and the integrated method of charge processing are:

[0035] (1) First, materials that cannot be crushed are manually selected, including sealed containers; materials that can cause explosions and fires; closed high-pressure gas storage cylinders; electric wires, steel wires, steel wires, steel wire ropes; toxic, harmful and dangerous products ;Steel pipe and its shaft materials;

[0036] (2) Send the remaining scrap iron and steel with complex components and suitable for crushing from the above (1) to the feeding chain conveyor 1 by the steel grabber, and the chain conveyor conveys it to the double-shaft shredding machine with a pressing device. Machine 3 performs primary crushing, and then primary crushed materials are sent to vertical crusher 5 by primary chain conveyor 4 for secondary crushing and kneading, so that scrap steel, non-ferrous metals, plastics and garbag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com