Paper reinforcement plant-based composite material and preparation method thereof

A composite material and plant-based technology, which is applied in the field of new reinforced plant-based composite materials and their preparation, can solve the problems of under-emphasized grass resource utilization, insignificant enhancement effect, and high requirements on raw material conditions, and achieves elimination of internal defects and avoidance of surface defects. The effect of damage and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The straw is sun-dried to constant weight and crushed into a mixture of chips and powder by a hay cutter. Weigh 1000 grams of pulverized raw materials, put them in a stirring tank, add 200 mL of water, and stir for 5 minutes to make the surface of the plant raw materials evenly wetted, then weigh 250 grams of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99%. Add silk to the raw material tank, stir for 5 minutes to mix the plant raw material and the adhesive evenly, put the mixed material into a stainless steel mold whose surface is wetted with water, lay a layer of paper inside the mold, and evenly sprinkle 5 1 gram of polyvinyl alcohol silk, spread the mixed straw scraps on the paper, repeat this for 3 more times, and finally sprinkle 5 grams of polyvinyl alcohol silk on the top layer of the plant material, then spread the last layer of paper, and close the mold. Preheat the platen of the hot press to 150°C, place the mold fi...

Embodiment 2

[0028]The grass cut from the lawn is dried to constant weight and crushed into a mixture of chips and powder by a hay cutter. Weigh 1000 grams of pulverized raw materials, put them in a stirring tank, add 200 mL of water, and stir for 5 minutes to make the surface of the plant raw materials evenly wetted, then weigh 250 grams of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99%. Add silk to the raw material tank, stir for 5 minutes to mix the plant raw material and the adhesive evenly, put the mixed material into a stainless steel mold whose surface is wetted with water, lay a layer of paper inside the mold, and evenly sprinkle 5 1 gram of polyvinyl alcohol silk, spread the mixed plant scraps on the paper, repeat this for 3 more times, and finally sprinkle a layer of 5 grams of polyvinyl alcohol silk on the top layer of the plant material, then spread the last layer of paper, and close the mold. Preheat the platen of the hot press to ...

Embodiment 3

[0030] The straw is sun-dried to constant weight and crushed into a mixture of chips and powder by a hay cutter. Weigh 1000 grams of pulverized raw materials, put them in a stirring tank, add 200 mL of water, and stir for 5 minutes to make the surface of the plant raw materials evenly wetted, then weigh 250 grams of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99%. Add silk to the raw material tank, stir for 5 minutes to mix the plant raw material and the adhesive evenly, put the mixed material into a stainless steel mold whose surface is wetted with water, lay a layer of paper inside the mold, and evenly sprinkle 5 1 gram of polyvinyl alcohol silk, spread the mixed straw scraps on the paper, repeat this process once more, and finally sprinkle a layer of 5 grams of polyvinyl alcohol silk on the top layer of plant material, then spread the last layer of paper, and close the mold . Preheat the platen of the hot press to 150°C, place t...

PUM

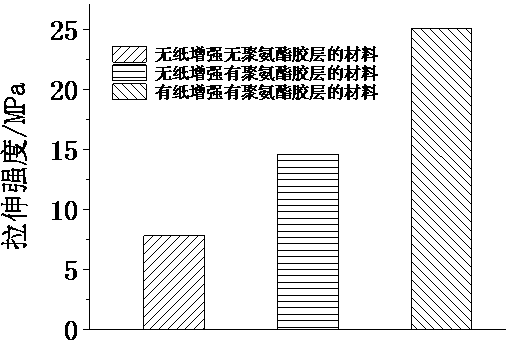

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com