Moving magnet non-contact liquid magnetization method and device

A non-contact, magnetizing device technology, applied in the fields of magnetic field/electric field water/sewage treatment, etc., can solve the problems of consumption, large electric power, and the magnetic field strength cannot be adjusted automatically, and achieves a low energy consumption, good magnetization effect and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

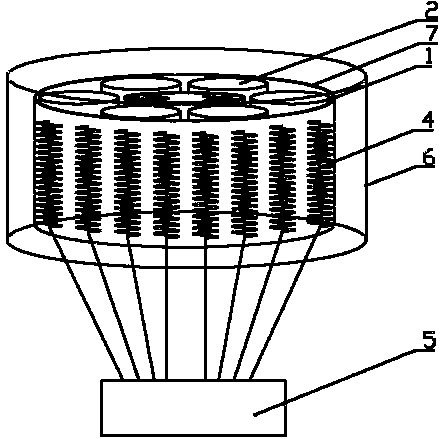

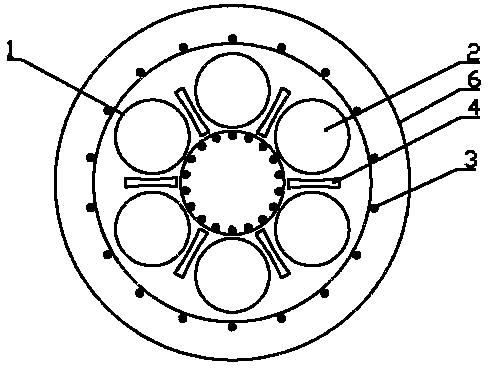

[0019] Such as figure 1 , figure 2 As shown, this embodiment includes a housing 7, a shield 6 arranged outside the housing 7, several containers 1 arranged in the housing 7, bottled liquid 2 arranged in the container 1, At least one pair of permanent magnets 3 with opposite polarities and at least one pair of induction coils 4 arranged on the outside of the container 1, and a DC positive and negative switching device 5 electrically connected to the induction coils 4, the number of the containers 1 and the The number of the permanent magnets 3 and the induction coils 4 can be set according to actual needs, but one container 1 needs to be equipped with at least one pair of permanent magnets 3 and at least one pair of induction coils 4, and the generation of the permanent magnets 3 The magnetic force lines generated by the induction coil 4 intersect vertically, the container 1 is in the shape of an annular cylinder, the container 1 is made of non-magnetic material, and several ...

Embodiment 2

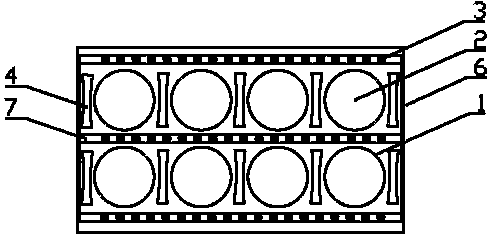

[0021] Such as image 3 As shown, the present embodiment is roughly the same as the embodiment, the difference is that the shell seat 7 of the present invention is square, and the eight containers 1 are divided into two rows and arranged in the space of the shell seat 7 in a rectangular array. In the cavity, two rows of containers 1 share the middle permanent magnet 3 , and a row of induction coils 4 is arranged on the other side.

Embodiment 3

[0023] Such as Figure 4 As shown, this embodiment is substantially the same as the embodiment, the difference is that in this embodiment, at least one pair of the electromagnets 3 are respectively located outside the side wall of the container 1, and at least one pair of the induction coils 4 They are respectively located on the top and bottom sides of the container 1, the induction coil 4 intersects with the magnetic force lines emitted by the electromagnet 3 to generate vibration, and the vibration of the magnetic force lines at different frequencies can cut water molecules of different sizes, so that The vibration frequency of water molecules increases, the energy level of electrons moving around the nucleus in water molecules increases, and the magnetized water becomes energy active water. This energy breaks the molecular chains of large molecular clusters of water and makes them into small molecular clusters. water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com