A method and device for deep removal of phosphorus and nitrogen from sewage

A deep, sewage technology, applied in the treatment of sewage or sludge, waste water, and water fields, can solve the problems of reduced total nitrogen and total phosphorus content, difficulty in reaching the standard of sewage treatment, and conflict of sludge age, etc., to reduce head loss and energy. consumption, good denitrification and phosphorus removal, and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the description of the drawings and the specific embodiments.

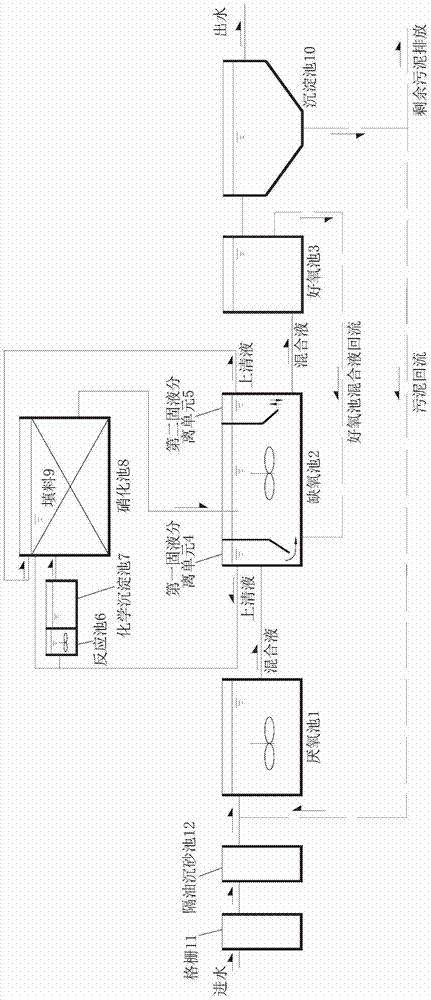

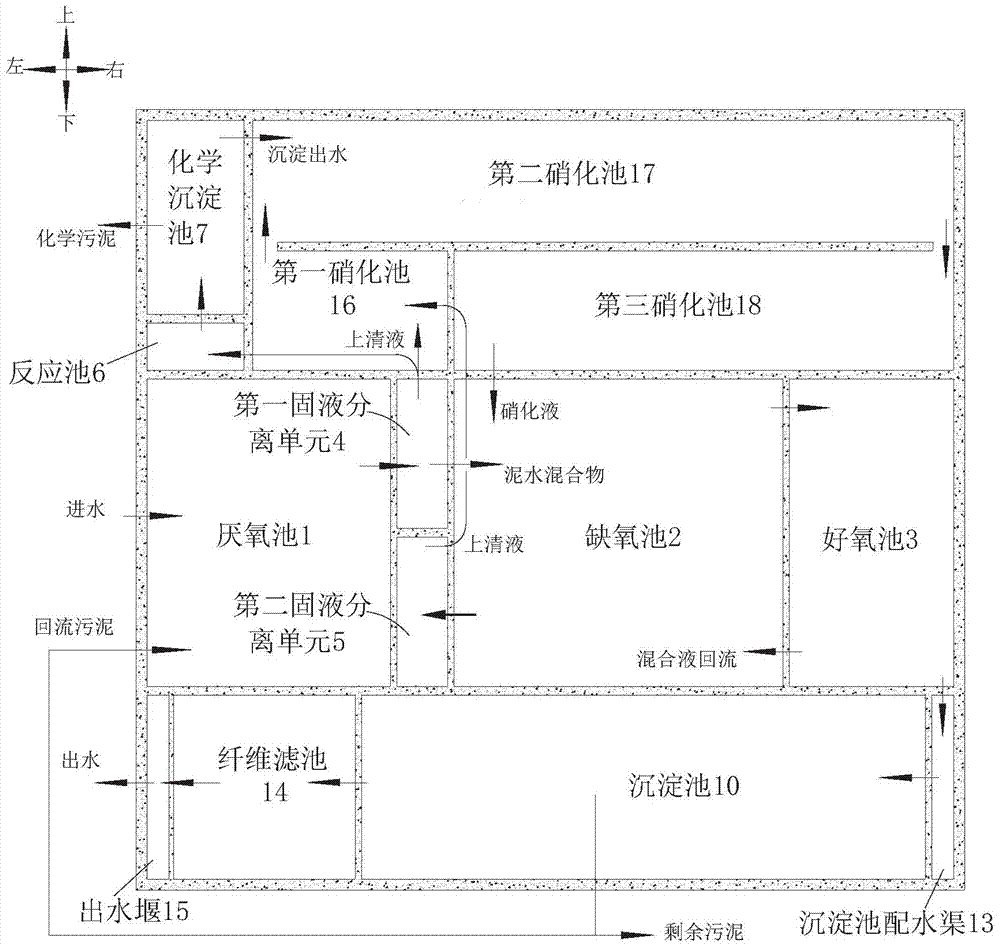

[0033] figure 2 with image 3 The middle number means: 1. Anaerobic tank; 2. Anoxic tank; 3. Aerobic tank; 4. The first solid-liquid separation unit; 5. The second solid-liquid separation unit; 6. Reaction tank; 7. Chemical sedimentation tank 8. Nitrification tank; 9. Filling; 10. Sedimentation tank; 11. Grid; 12. Oil separation and grit sedimentation tank; 13. Sedimentation tank distribution channel; 14. Fiber filter; 15. Water outlet weir; 16. First Nitrification tank; 17, the second nitrification tank; 18, the third nitrification tank.

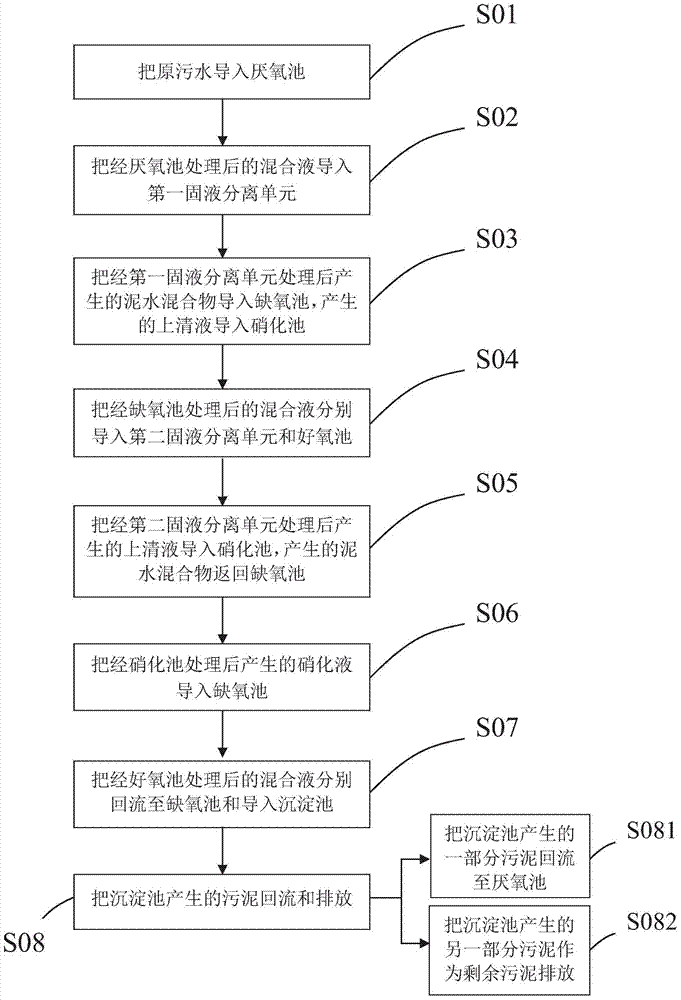

[0034] Such as figure 1 As shown, the present invention is a method for deep removal of phosphorus and nitrogen from sewage, which includes the following steps:

[0035] S01. Lead the raw sewage into the anaerobic tank 1; the raw sewage is processed by the grid 11 and the oil-separating grit tank 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com