Photodiffusion composite and preparation method thereof

A composite material and light diffusion technology, applied in the field of the preparation of new lighting chemical materials, can solve the problems of high cost and poor dispersibility, achieve high light transmittance and haze, solve the problem of uneven dispersion and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The light-diffusing composite material provided in this embodiment is composed of raw materials in the following weight ratio:

[0049] Polycarbonate 87.5%~96%

[0050] Organic light diffusion masterbatch 4%~12%

[0051] Inorganic light diffusion masterbatch 0~0.5%

[0052] Wherein, the organic light diffusion masterbatch is composed of raw materials in the following weight ratio:

[0053] Polycarbonate 90%

[0054] Light Diffuser 1 10%

[0055] Wherein, the inorganic light diffusion masterbatch is composed of raw materials in the following weight ratio:

[0056] Polycarbonate 90%

[0057] Light Diffuser 2 10%.

[0058] Said polycarbonate is bisphenol A polycarbonate with a melt index of 0.8-1.2 g / min.

[0059] The light diffusing agent 1 is polymethyl methacrylate and spherical silicone (KMP590), with a particle size of 1-5 um.

[0060] The light diffusing agent 2 is titanium dioxide with a particle size of 10-30 nm.

[0061] A method for preparing the above-m...

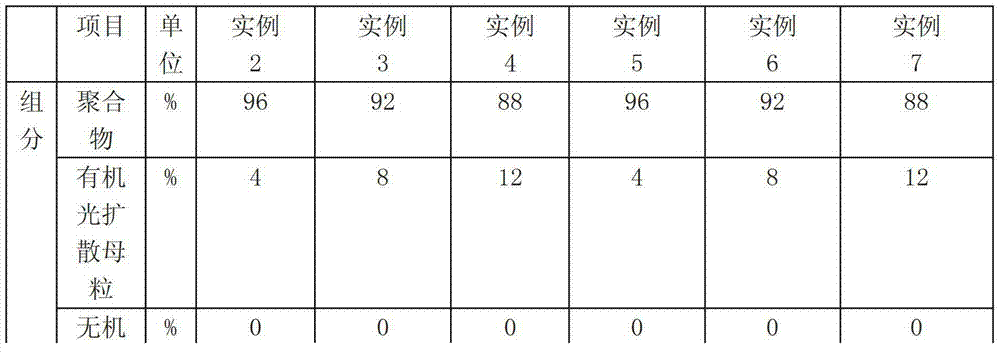

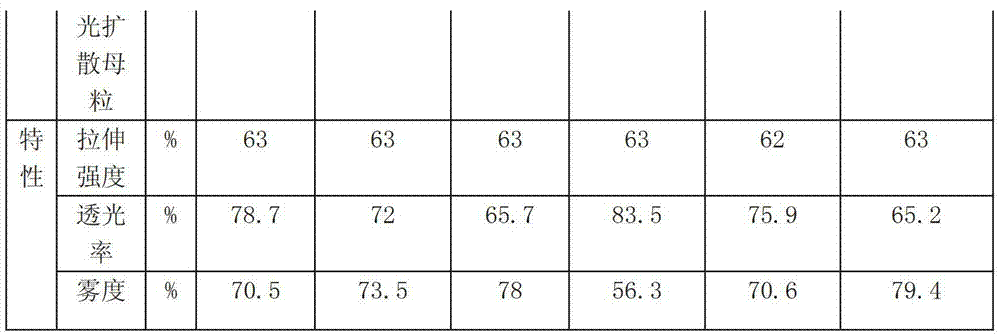

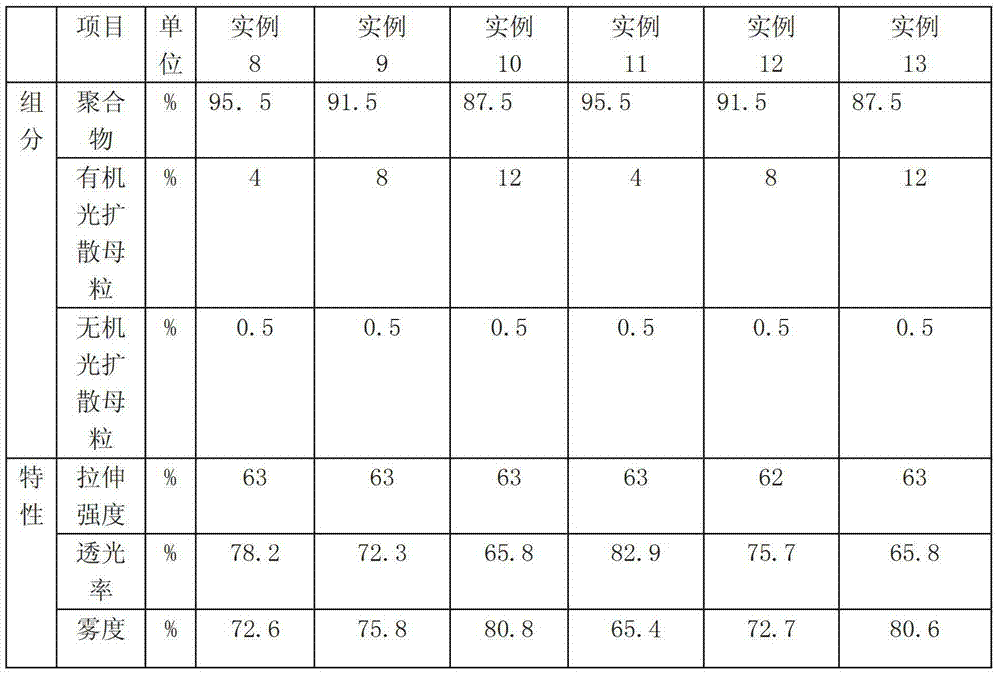

Embodiment 2

[0082] The light-diffusing composite material provided in this embodiment and its preparation method are basically the same as in Example 1, except that:

[0083] The light-diffusing composite material provided by the present invention is composed of raw materials in the following weight ratio:

[0084] Polycarbonate 96%

[0085] Organic Light Diffusion Masterbatch 4%

[0086] Wherein, the organic light diffusion masterbatch is composed of raw materials in the following weight ratio:

[0087] Polycarbonate 90%

[0088] Polymethylmethacrylate 10%;

[0089] A method for preparing the above-mentioned light-diffusing composite material, comprising the steps of:

[0090] (1) Preparation of organic light diffusion masterbatch:

[0091] (11) Take raw materials according to the following weight ratio:

[0092] Polycarbonate 90%

[0093] Polymethylmethacrylate 10%

[0094] (12) Mix polycarbonate and polymethyl methacrylate, and use a twin-screw machine to extrude and granulate....

Embodiment 3

[0101] The light-diffusing composite material provided in this embodiment and its preparation method are basically the same as those in Examples 1 and 2, except that:

[0102] The light-diffusing composite material provided by the present invention is composed of raw materials in the following weight ratio:

[0103] Polycarbonate 92%

[0104] Organic Light Diffusion Masterbatch 8%

[0105] Wherein, the organic light diffusion masterbatch is composed of raw materials in the following weight ratio:

[0106] Polycarbonate 90%

[0107] Polymethylmethacrylate 10%;

[0108] A method for preparing the above-mentioned light-diffusing composite material, comprising the steps of:

[0109] (1) Preparation of organic light diffusion masterbatch:

[0110] (11) Take raw materials according to the following weight ratio:

[0111] Polycarbonate 90%

[0112] Polymethylmethacrylate 10%

[0113] (12) Mix polycarbonate and polymethyl methacrylate, and use a twin-screw machine to extrude a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com