Operation pipe system for cell factory and application thereof

A pipeline system and pipeline technology, applied in the field of biochemistry, can solve the problems of uneven cell digestion, slow operation speed, cumbersome operation, etc., and achieve the effects of improving culture efficiency, increasing use efficiency and shortening operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Cell Factory Operation Piping System

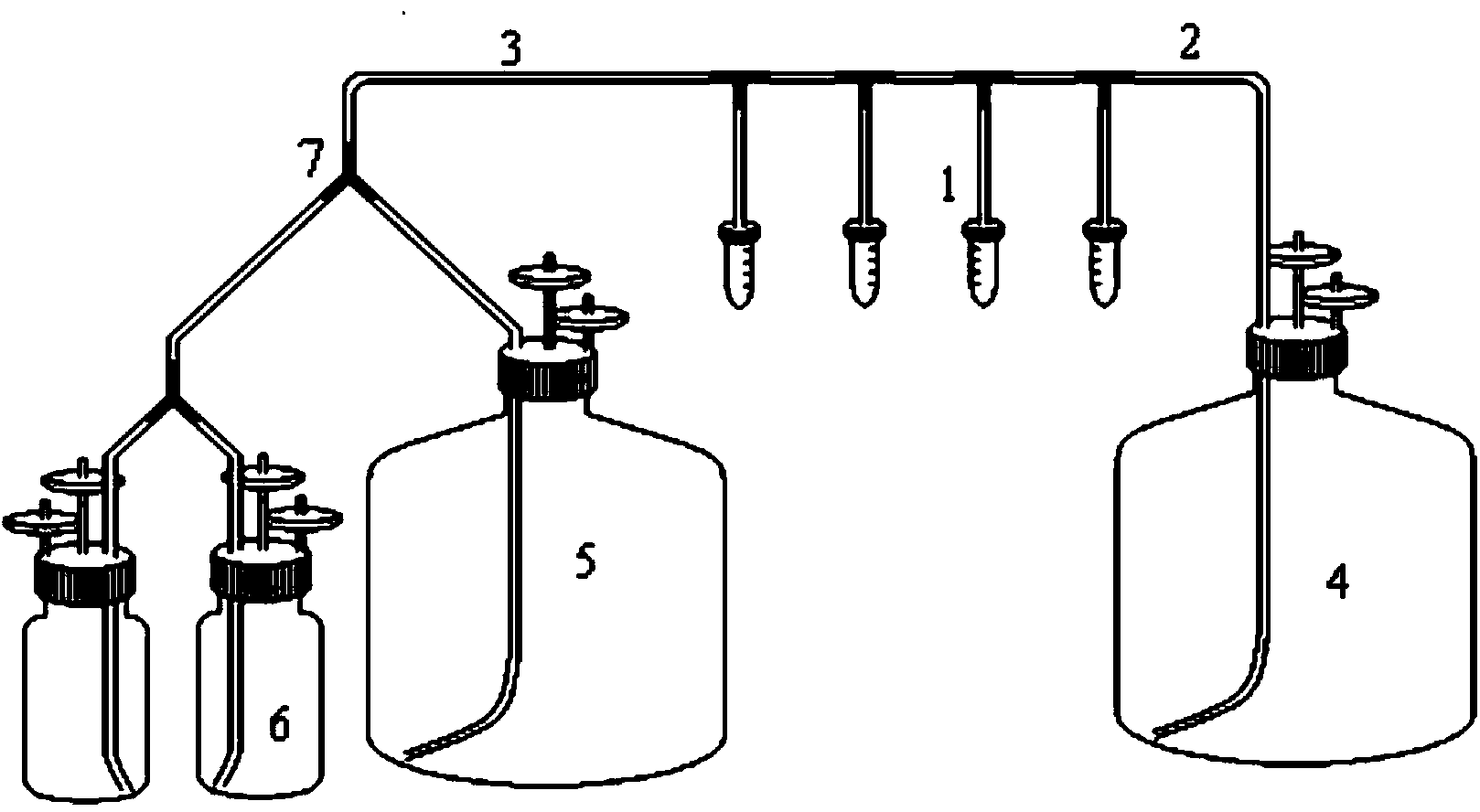

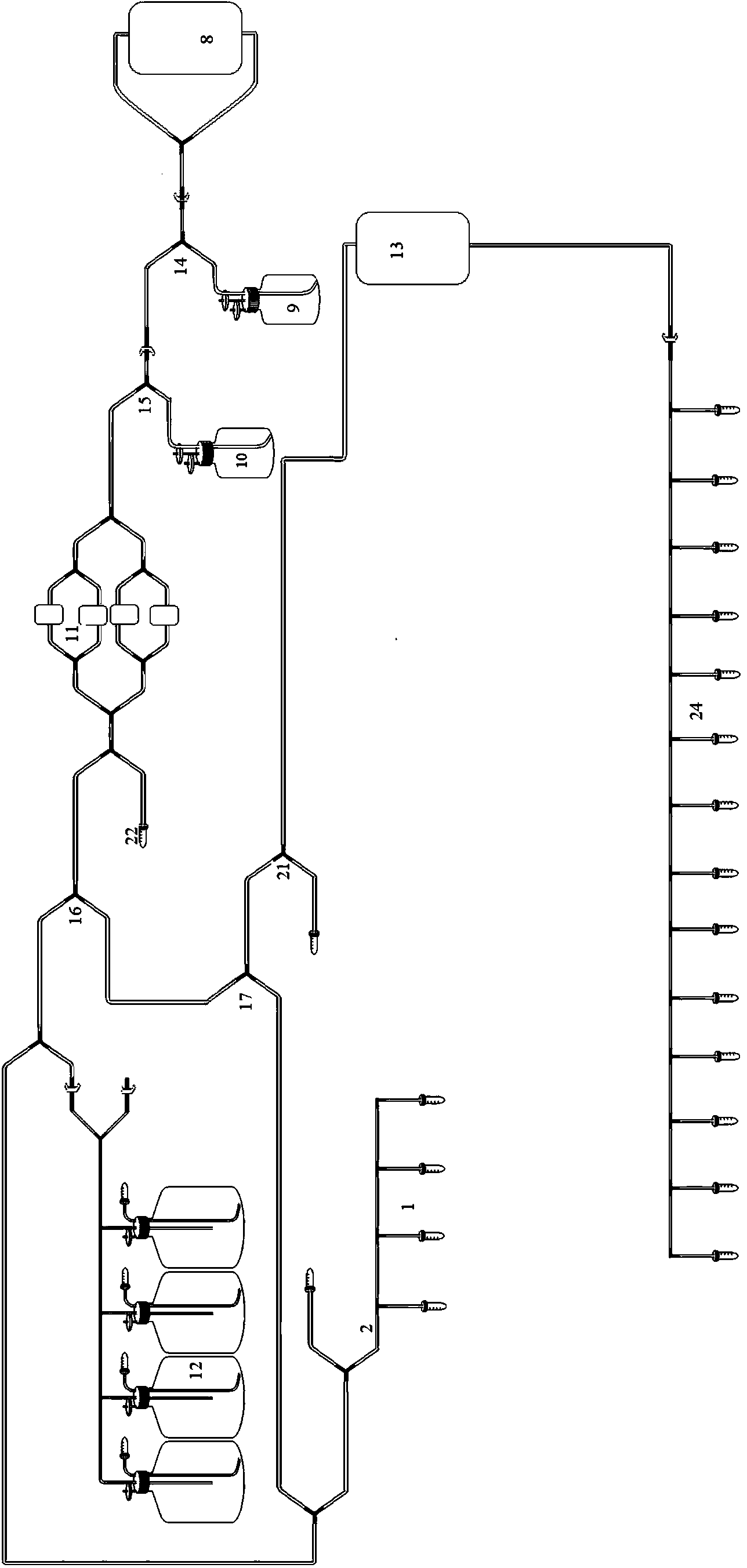

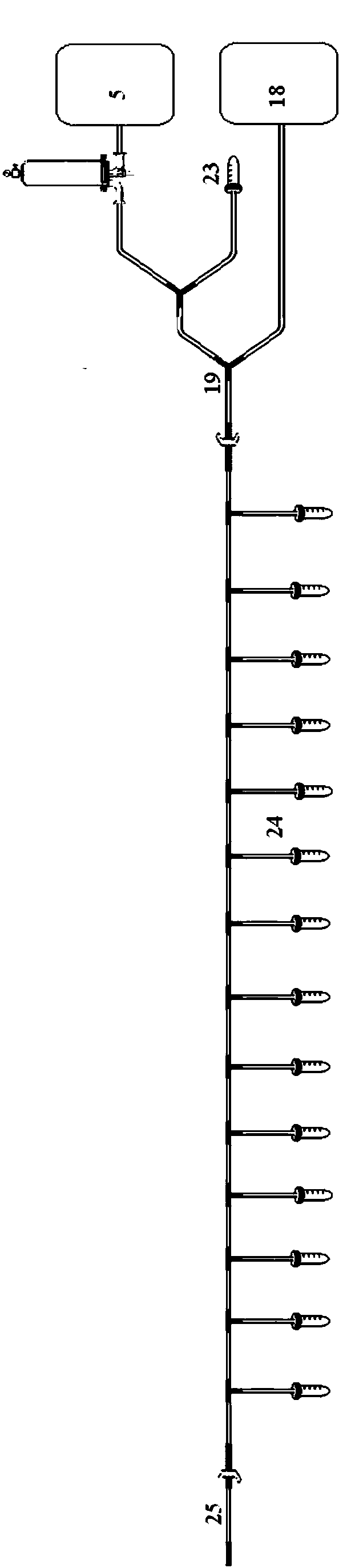

[0049] It includes a cell factory 1 and an inlet pipeline 2 and an outlet pipeline 3 connected to the cell factory. The inlet pipeline 2 and the outlet pipeline 3 can be replaced with the washing digestive system ( figure 1 ), poisoning system ( figure 2 ) or harvesting system ( image 3 )connect;

[0050]1) The washing and digestion system includes a supernatant tank 4, a buffer tank 5 and a digestate tank 6. The buffer tank 5 and the digestate tank 6 are connected to the outlet pipe 3 and the tee 7 through pipes. The above-mentioned supernatant liquid tank 4 is connected with the liquid inlet pipeline 2;

[0051] 2) The poison receiving system includes a liquid preparation tank 8, a serum container 9, a serum-free liquid tank 10, a filter 11, a serum-free dispersion liquid tank 12, a suspension tank 13, and a second cell factory 24; the liquid preparation tank 8 Through pipeline, serum container 9 is connected on ...

Embodiment 2

[0057] 1. Cell factory operation piping system used in washing and digestion operations ( figure 1 )

[0058] ① The liquid inlet pipe 2 is clamped with a hemostat, and the liquid outlet pipe 3 is opened and connected to a peristaltic pump. After connecting to the first cell factory 1, the Vero cell supernatant is discharged into the 50L supernatant tank 4 .

[0059] ②Use a hemostat to close the outlet pipe 3, connect the inlet pipe 2 to the peristaltic pump, clamp the pipes from 6 to the tee 7 of the 4L digestive solution tank, and keep the pipe of the buffer tank 5 unblocked. The PBS buffer solution in the tank 5 is added to the first cell factory 1 for washing;

[0060] ③ After washing, drain the PBS in the first cell factory 1 into the buffer tank 5;

[0061] ④ The peristaltic pump is still connected to the liquid inlet pipeline 2, the pipeline of the buffer filling 5 and the liquid inlet pipeline 2 are clamped with a hemostat, and the pipelines of the digestive solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com