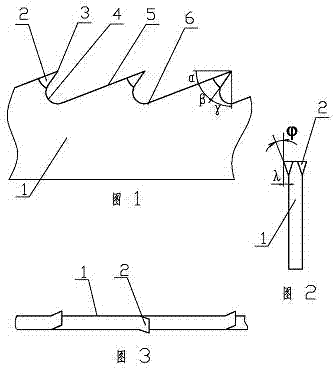

Back material of bi-metal band saw blade and band saw blade made of back material

A bimetal band and band saw blade technology, applied in the direction of metal sawing equipment, metal processing equipment, sawing machine tools, etc., can solve the problems affecting the strength of the tool, large equivalent stress, etc., to improve productivity and improve the resistance to spring reduction , the effect of inhibiting the formation and growth of crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The alloy composition and mass percentage (Wt%) of the back material of the bimetal band saw blade of the present invention are: C: 0.32%; Si: 0.25%; Mn: 0.85%; Nb: 0.002%; B: 0.001%; Mo: 1.12% ; Cr: 1.2%; V: 0.31%; Al: 0.015%; N: 0.012%; Ni: 0.66%; S: 0.003%;

[0034] The smelting process of the above alloy materials is: molten iron pretreatment and converter steelmaking, LF refining, VD vacuum treatment, tundish continuous casting. The equipment used in the smelting process includes the thyristor smelting furnace KGPS3, LF-6 refining furnace, and VD vacuum refining furnace.

[0035] Hot metal pretreatment and converter steelmaking, the temperature of the hot metal is 1335°C after desulfurization pretreatment. Converter smelting adopts double slag operation, and the slag is removed to remove P. To control the tapping temperature of the converter, the ladle is required to be clean, the bottom blowing is smooth, and there is no edge. Converter tapping adopts slag bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com