Electrostatic spinning device for preparing nanofibers

A technology of electrospinning and nanofibers, which is applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of commercial production difficulties, insufficient technology, complex equipment, etc., and achieves easy industrialization and implementation The effect of low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

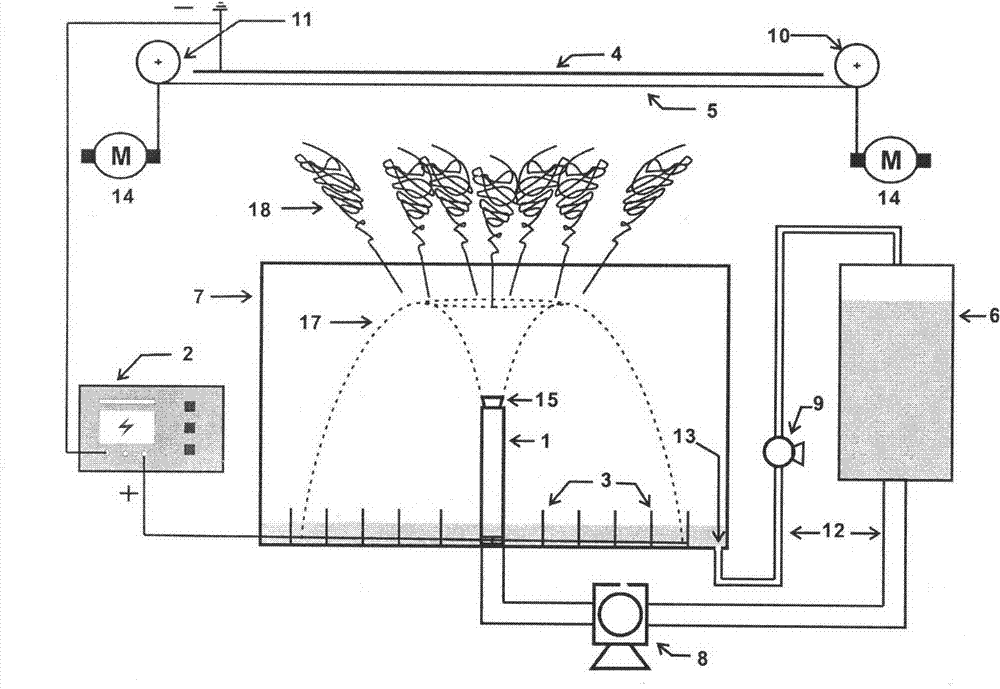

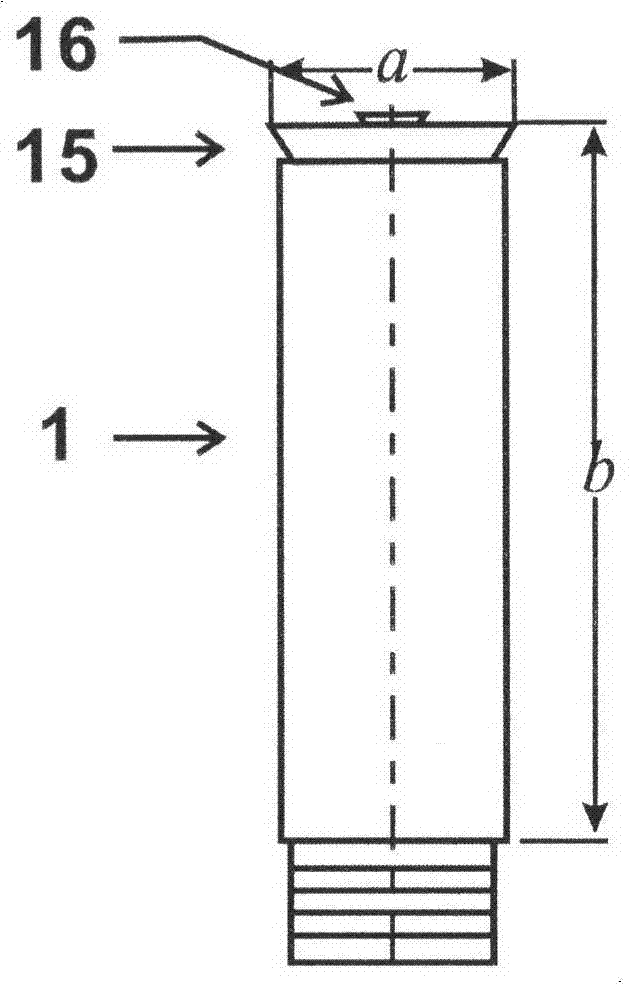

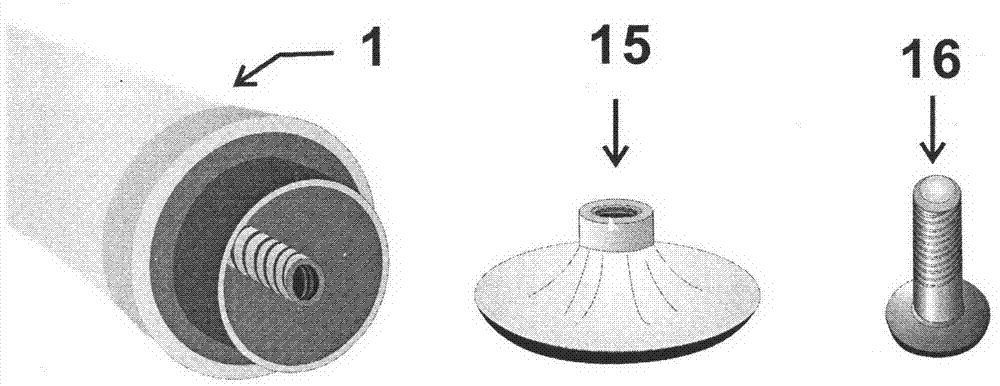

[0027] Design an electrostatic spinning device to improve the efficiency of nanofiber preparation, including a liquid jet 1, a high-voltage electrostatic generator 2, a needle electrode 3, a plate electrode 4, a receiving curtain 5, a liquid storage tank 6, a spinning tank 7, and a sending Liquid pump 8, suction pump 9, curtain delivery roller 10, roller shutter roller 11, duct 12, drain hole 13, motor 14, pressure nozzle 15, fixing screw 16, bellflower-like liquid film 17, jet 18, spray tube 1′, such as figure 1 Shown. Among them, the height of the nozzle 1'in the nozzle 1 is 50mm and the diameter is 20mm, the height of the nozzle 15 in the nozzle 1 is 8mm, the diameter is 30mm, and the inclination angle of the nozzle 15 is 80°, such as figure 2 , 3 , 6; the spinning pool 7 is circular, with a diameter of 200mm and a height of 80mm, made of glass, such as Figure 4 As shown; needle electrode 3 length is 10mm, diameter is 0.5mm, solid structure; plate electrode 4 length and wid...

Embodiment 2

[0030] This embodiment uses basically the same device and process as in embodiment 1, such as figure 1 Shown. The changes are: the height of the sprayer 1 is 40mm, the diameter is 22mm, the height of the pressure nozzle 15 of the sprayer 1 is 6mm, the diameter is 36mm, and the inclination angle of the pressure nozzle 15 is 60°, such as figure 2 , 3 , 7; the spinning pool 7 is square, the length and width are both 60mm, and the height is 65mm, made of organic glass, such as Figure 5 As shown; needle electrode 3 has a length of 20mm, a diameter of 0.9mm, and a hollow structure; the plate electrode 4 has a length and width of 80mm and a thickness of 0.7mm. The distance between the plate electrode 4 and the top of the spinning cell 7 is 40mm, and the plate electrode 4 There is a receiving curtain 5 with a width of 80mm and unlimited length at 0.5mm below.

[0031] Before spinning, weigh 1000 grams of polyvinylpyrrolidone (PVP K-30) powder, and dissolve it in a mixed solvent with a m...

Embodiment 3

[0033] This embodiment uses basically the same device and process as in embodiment 1, such as figure 1 Shown. The changes are: the height of the sprayer 1 is 60mm and the diameter is 16mm, the height of the pressure nozzle 15 of the sprayer 1 is 8mm, the diameter is 24mm, and the inclination angle of the pressure nozzle 15 is 20°, such as figure 2 , 3 , 4 and 8; the spinning pool 7 is circular, with a diameter of 60mm, a height of 80mm, and glass material, such as Figure 4 As shown; needle electrode 3 is 30mm in length, 0.6mm in diameter, solid structure; flat electrode 4 is 70mm in length and width, thickness is 1.5mm, the distance between flat electrode 4 and the top of spinning cell 7 is 30mm, flat electrode 4 There is a receiving curtain 5 with a width of 70mm and unlimited length at 1.5mm below.

[0034] Before spinning, weigh 500 grams of polyacrylonitrile polymer powder and mix it with the solvent dimethylformamide at a mass ratio of 12%. After heating in a water bath (50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com