Device and method for controlling RWD (reaming while drilling) drilling pressure distribution relationship

A technology of reaming while drilling and weight-on-bit, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc. It can solve the problem of the difficulty in correctly matching the design of pilot drill bits and reamers, ensuring the safety and stability of reaming operations, The problem of low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

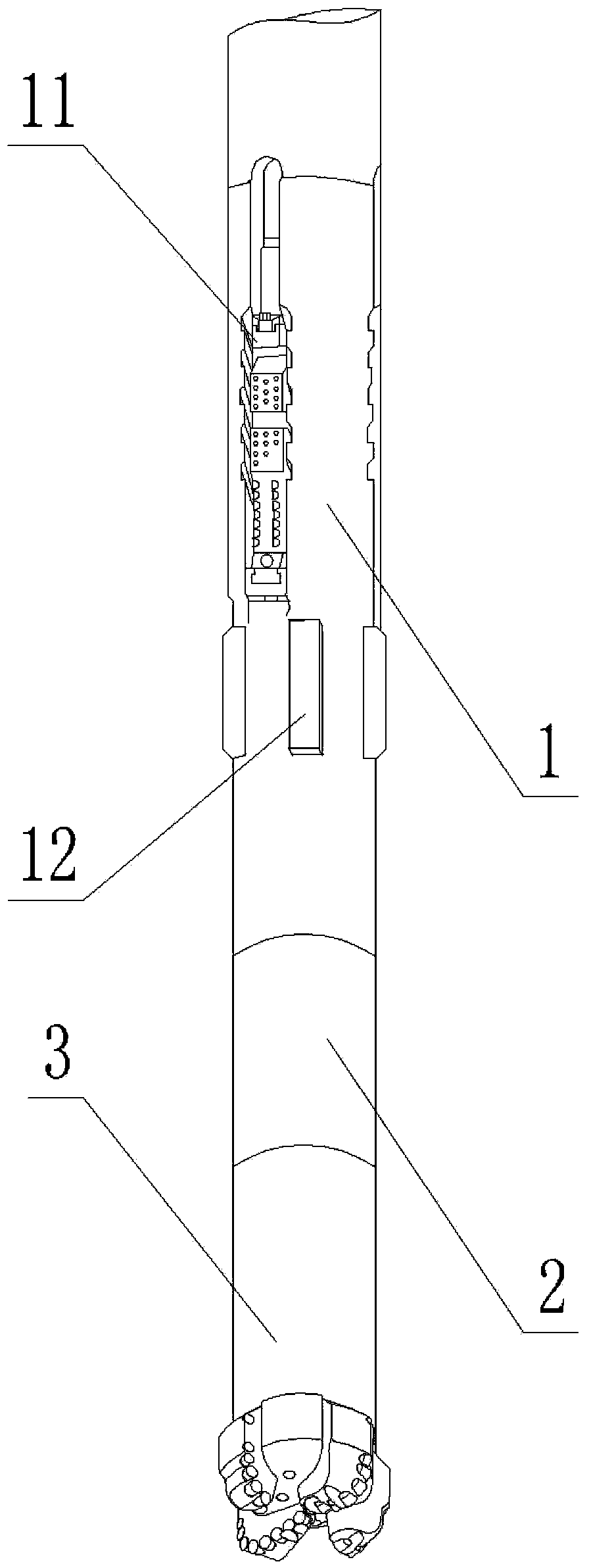

[0048] This embodiment provides a device for controlling the weight-on-bit distribution relationship of reaming while drilling, see figure 2 , the device includes a reamer while drilling 1, a short drill collar 2 and a pilot bit 3, the reamer 1 is connected to the upper end of the short drill collar 2, and the lower end of the short drill collar 2 is connected to the pilot bit 3 At least one reaming tool assembly 11 is arranged on the reamer while drilling 1 , and the diameter of the pilot bit 3 is smaller than the outer diameter of the reamer while drilling 1 when the reaming tool assembly 11 is expanded. The pilot bit 3 is arranged at the lowermost end of the device, and the pilot bit 3 is used to break the formation to form a pilot hole with a smaller diameter; the reamer 1 is installed on the upper end of the drill string of the device, and the expanded The cutting diameter is larger than that of the pilot bit 3, and the reamer 1 expands the pilot hole into a main wellbor...

Embodiment 2

[0053] This embodiment provides a device for controlling the weight distribution relationship of reaming while drilling. The device includes a reamer while drilling 1, a short drill collar 2 and a pilot bit 3. The connection relationship between the drill collar 2 and the pilot bit 3 is the same as that in the first embodiment, and the components and the connection relationship of the reamer 1 of the device are the same as those in the first embodiment or can be implemented Example 1 has reasonable improvement and optimization on the basis of the same function.

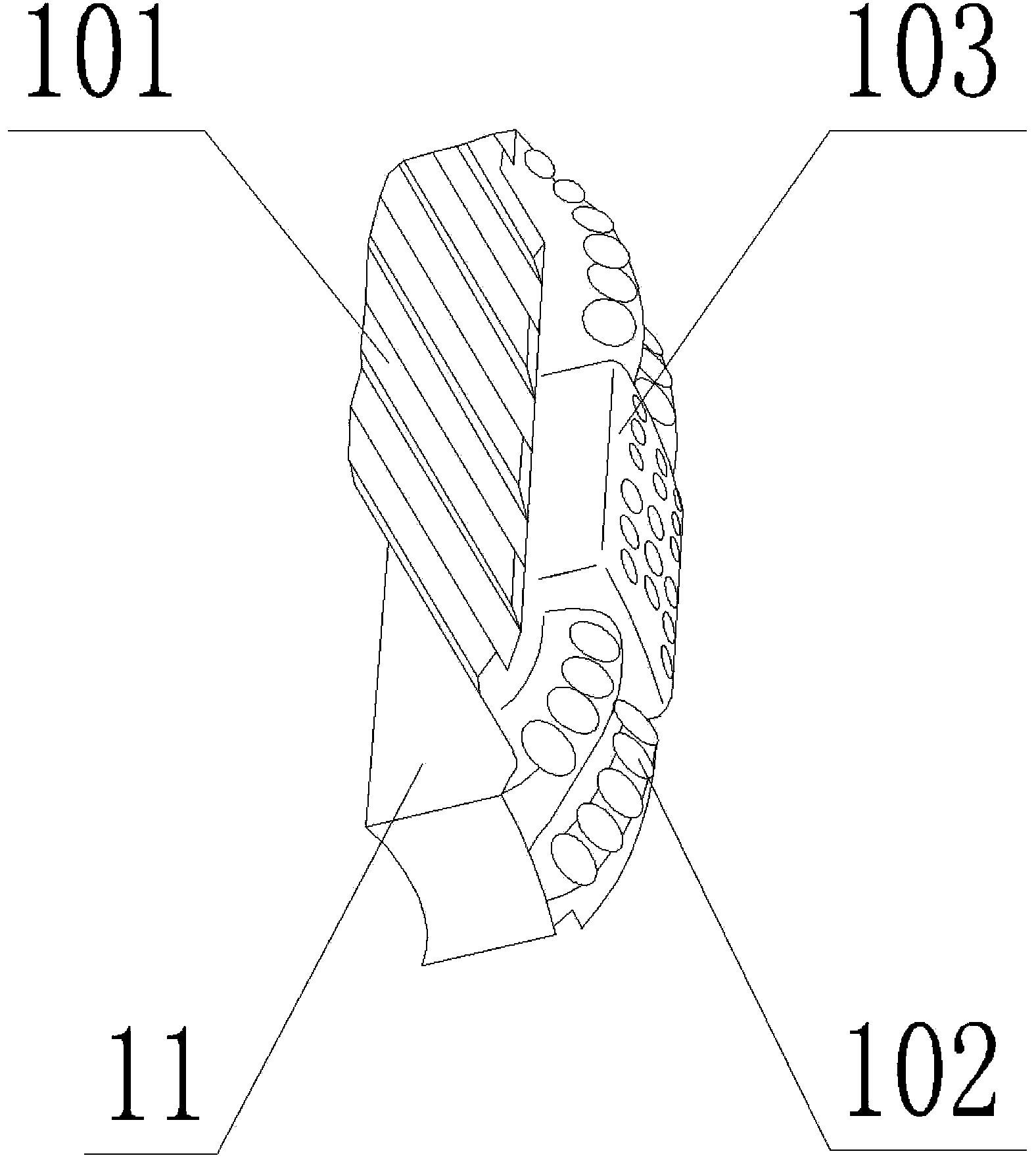

[0054] see in conjunction Figure 4 and Figure 5 , the crown of the pilot drill bit 3 is provided with a plurality of pilot blades 31, and between each pilot blade 31 is a return chip groove 32, and the end of the pilot blade 31 is provided with a wear-resistant pad 301, and a plurality of The edge of the same side of the pilot blade 31 is provided with drill cutting teeth 302 , and the wear-resistant pad 301 parti...

Embodiment 3

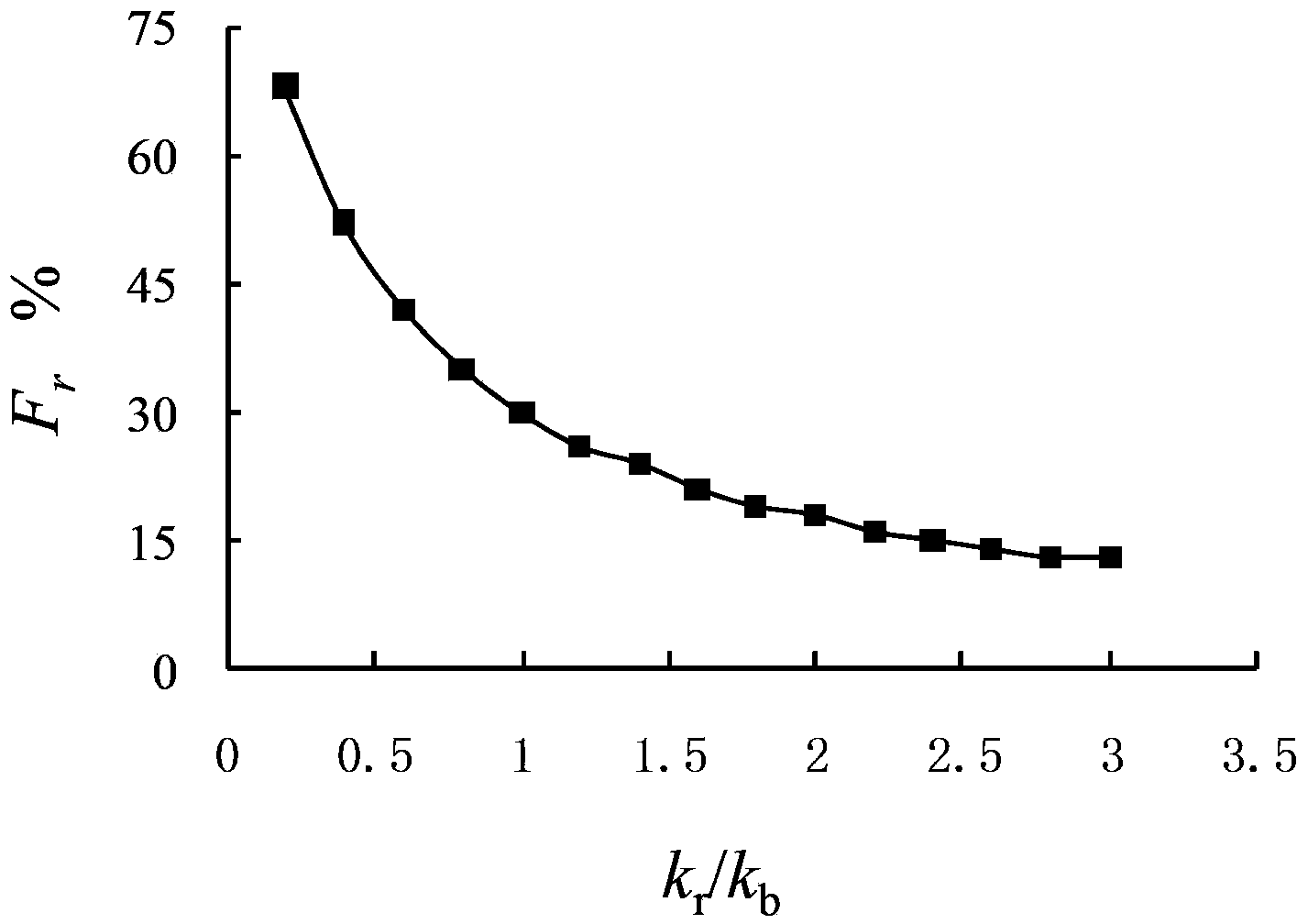

[0057] The embodiment of the present invention provides a method for controlling the weight-on-bit distribution relationship of reaming-while-drilling, the distribution ratio f w In addition to the geometric area ratio of the pilot hole and the main wellbore, the most important factors are the formation characteristics and the cutting ability of the drilling tool itself. The method includes, according to the Teale rock specific work expression:

[0058] E s = W A + 120 π · Ω · W · T A · v - - - ( 1 )

[0059] In formula (1), E s is the specific work of the rock; W is the weight on bit; A is the cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com