Automatic pulling service system and operating method

An operation system and operation method technology, which is applied to the automatic lifting and lowering operation system and the field of operation, can solve the problems of occupying non-technical operation time of the lifting device, affecting the working independence of the lifting device, and failing to give full play to the equipment efficiency. Compact, avoid frequent commutation, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, describe in detail by embodiment:

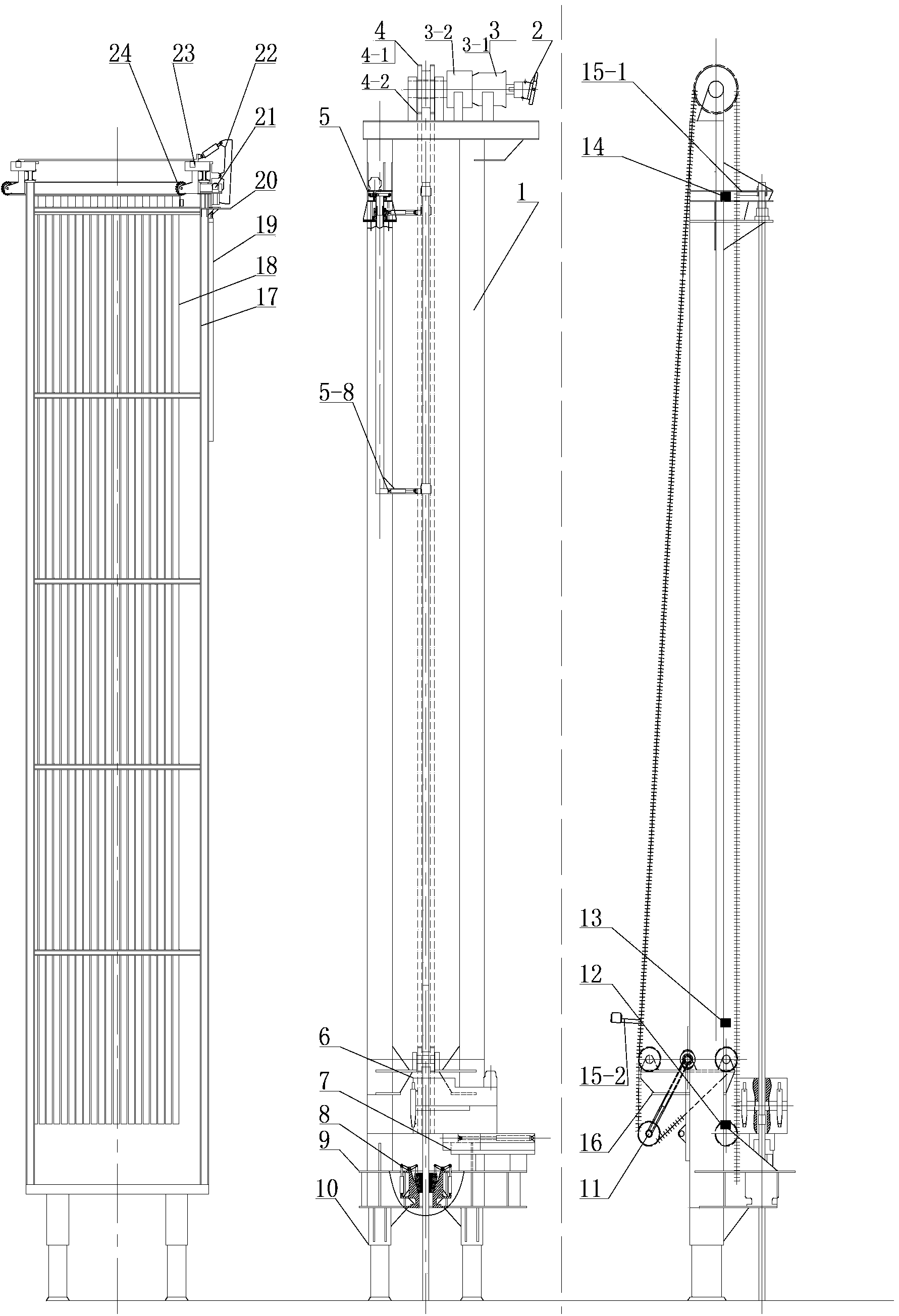

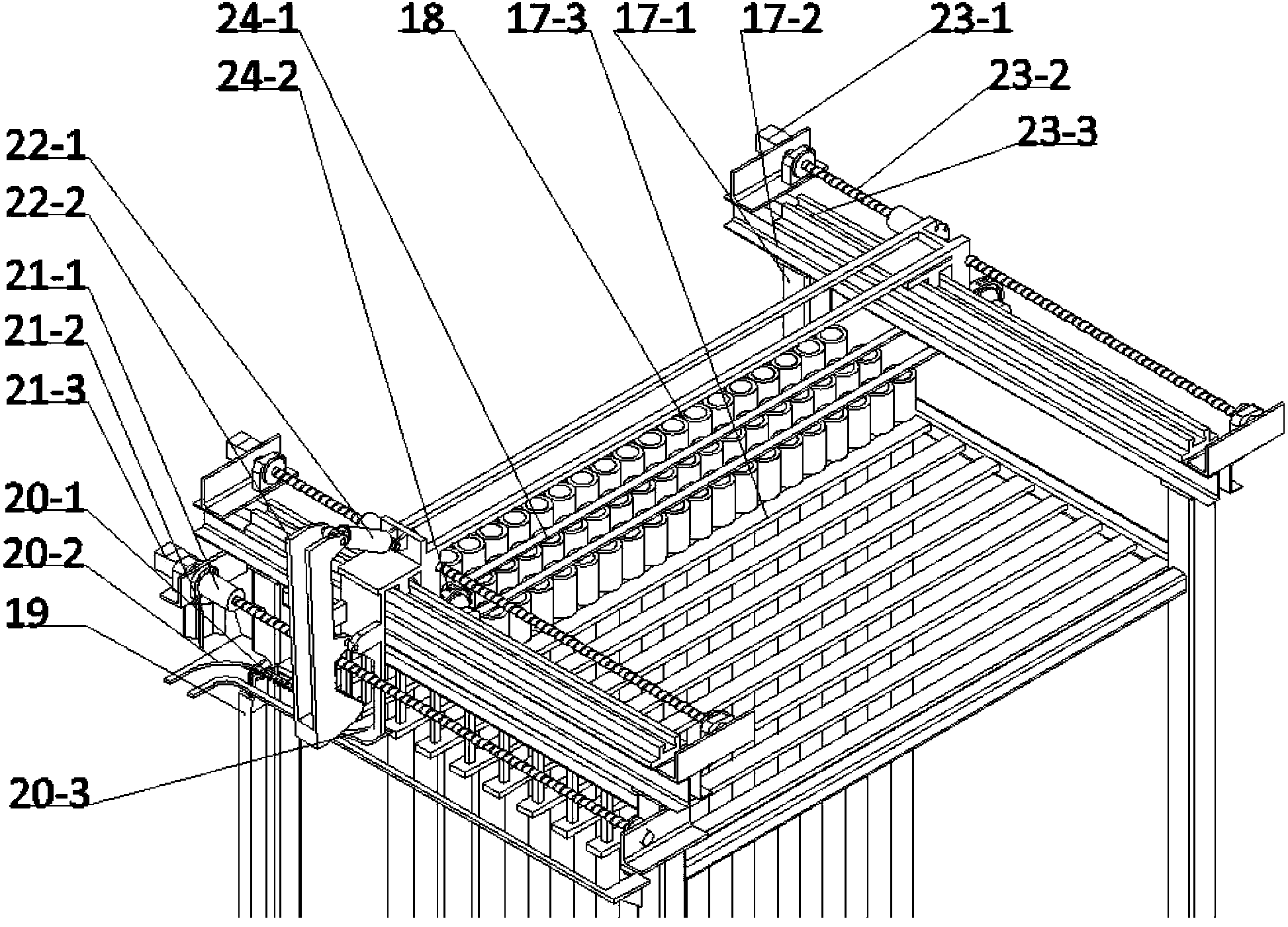

[0036] Such as figure 1 As shown, the automatic lifting operation system mainly includes an automatic lifting device and an automatic string processing device.

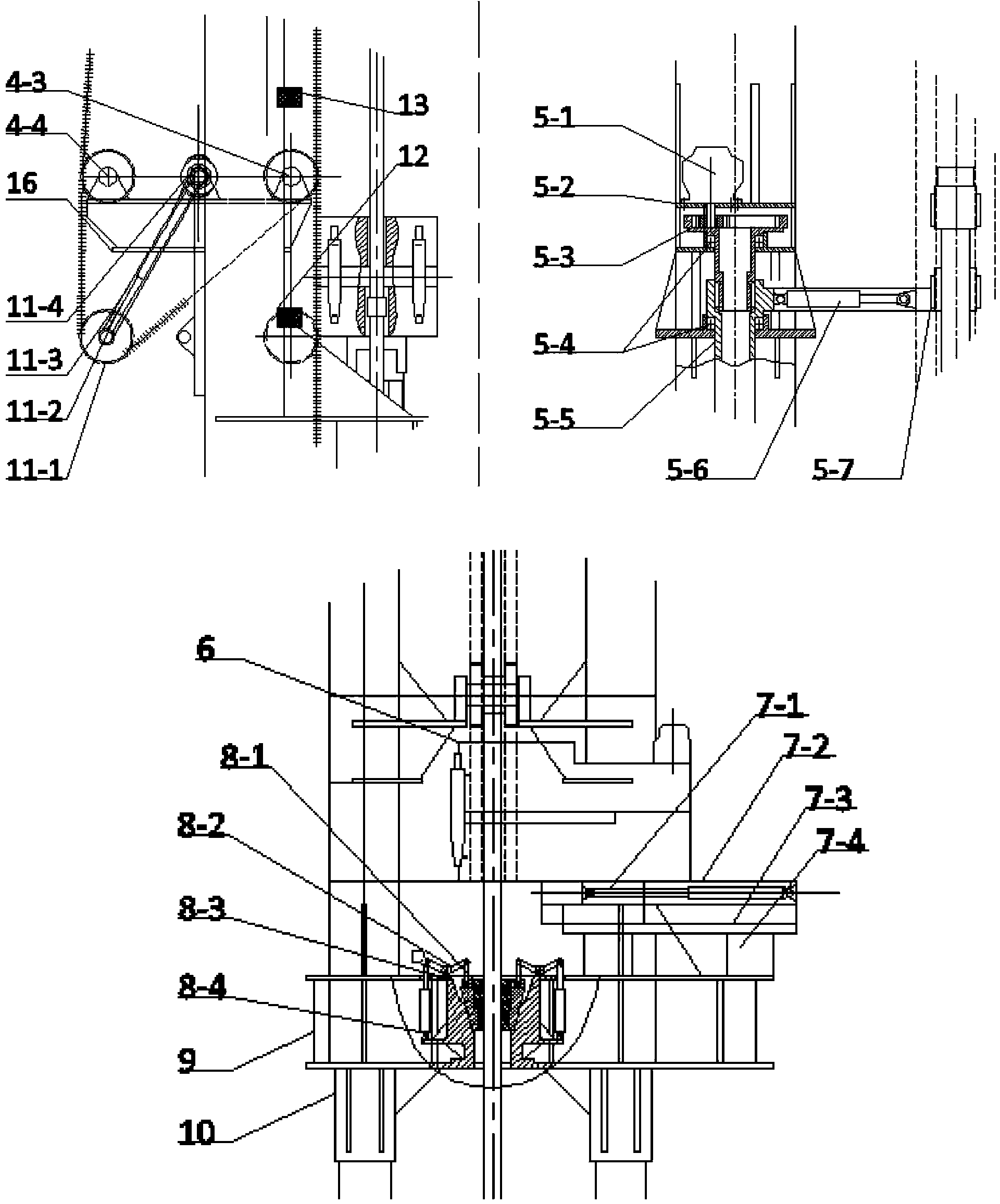

[0037] The automatic lifting device, which acts as a frame, mainly includes a parallel support 1, a wellhead workbench 9, a sprocket support platform 16 and a top support 5-1. The above components are mainly formed by welding; the main working mechanism is a chain circulation Lifting mechanism, including driving sprocket 4-1, transmission chain 4-2, front and rear guide wheels 4-3 and 4-4, chain give way mechanism 11, and main clamp 15 on two sets of special chain links of chain; There is a column transmission assembly 5, which is installed on the top bracket 5-2, including the hydraulic motor 5-1, the internal gear reduction device 5-3, the thrust bearing 5-4, the main rotating arm 5-5, and the main transmission arm telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com