Construction method of underground diaphragm wall with movable door sealing mechanism and reserved opening in the wall

A technology of reserving holes and sealing doors, applied in infrastructure engineering, artificial islands, earthwork drilling, etc., can solve problems such as reducing structural safety, low construction efficiency, increasing tool wear, etc., to reduce the risk of mechanical failure, Save material and labor, ensure strength and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

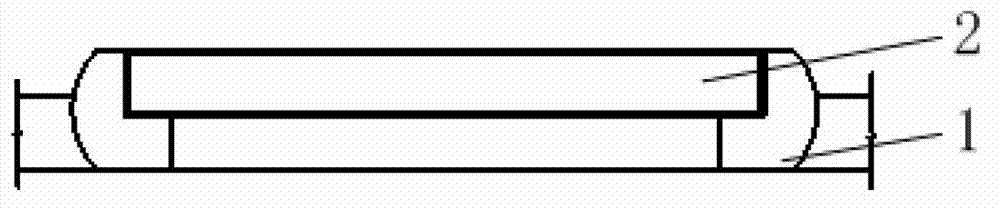

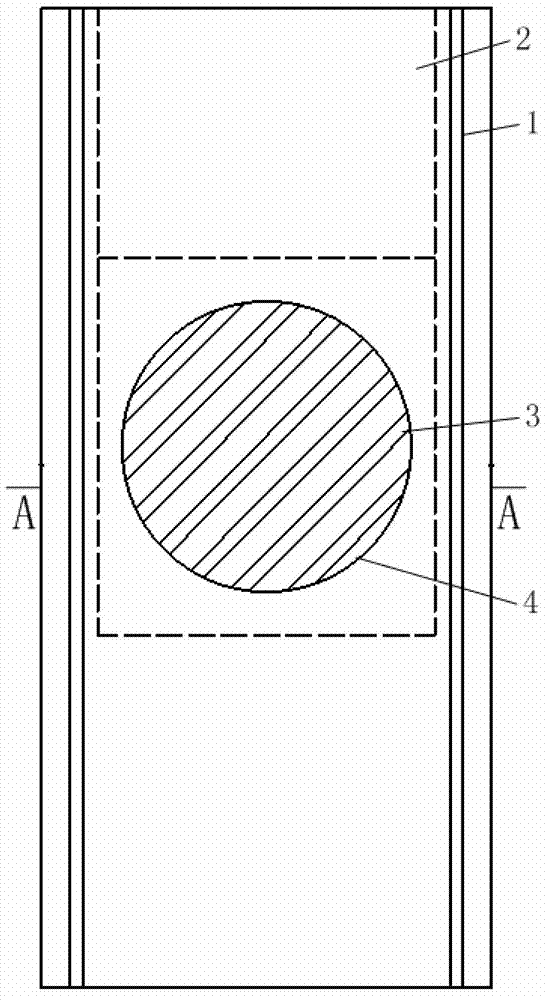

[0058] A movable door sealing mechanism in the wall, such as figure 1 and figure 2 As shown, the movable door sealing mechanism 2 in the wall is arranged on the outside of the continuous wall 1. The movable door sealing mechanism in the wall includes a door sealing main structure and at least one door sealing sub-component. The door sealing section and the connecting door sealing section are connected by connecting joints.

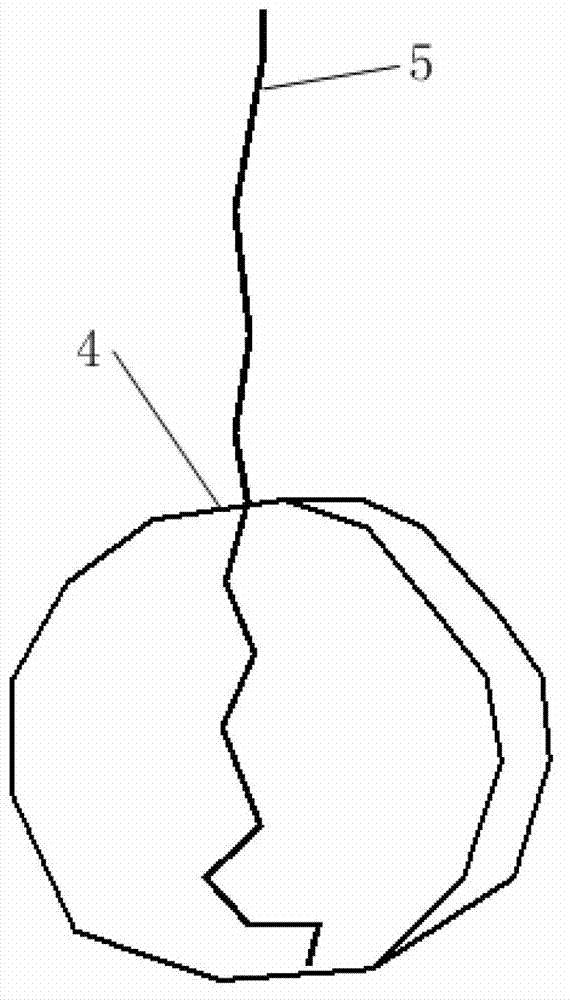

[0059] The sub-components of door sealing include post-tensioning anti-pressure loading device, door sealing chute, water sealing device for door sealing seam, contact surface friction reduction device, liquid injection pipeline, auxiliary door sealing lifting device, door sealing mechanical deformation and water seepage monitoring device, post-tensioning The anti-pressure loading device is installed in the middle of the door sealing section of the hole, the door sealing chute is set around the main structure of the door sealing, and the water sealing de...

Embodiment 2

[0076] A construction method for an underground diaphragm wall with a reserved opening and a movable door sealing mechanism device in the wall, including a diaphragm wall width 1 and a movable door sealing device 2, the designed geometric dimensions and stratum parameters, groundwater, foundation pit excavation depth, and opening position And related to the characteristics of the structural materials used, when the thickness of the wall exceeds the thickness of the ordinary wall, over-excavation must be carried out; the reinforcement reinforcement in the wall structure 6 of the continuous wall must be encrypted at the position of the hole circle to ensure that the wall width of the hole is not affected. The force is stable, a circle of steel plates is pre-buried around the hole and a connecting flange is provided to facilitate the connection between other components and the hole ring and strengthen the overall stability of the hole ring; the reserved hole 3 can be round or squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com