Motor lateral external one drive two counter-rotating axial flow fan

An axial flow fan, external technology, applied in the direction of machine/engine, pump device, mechanical equipment, etc., can solve the problems of difficult maintenance, poor adaptability, and low safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

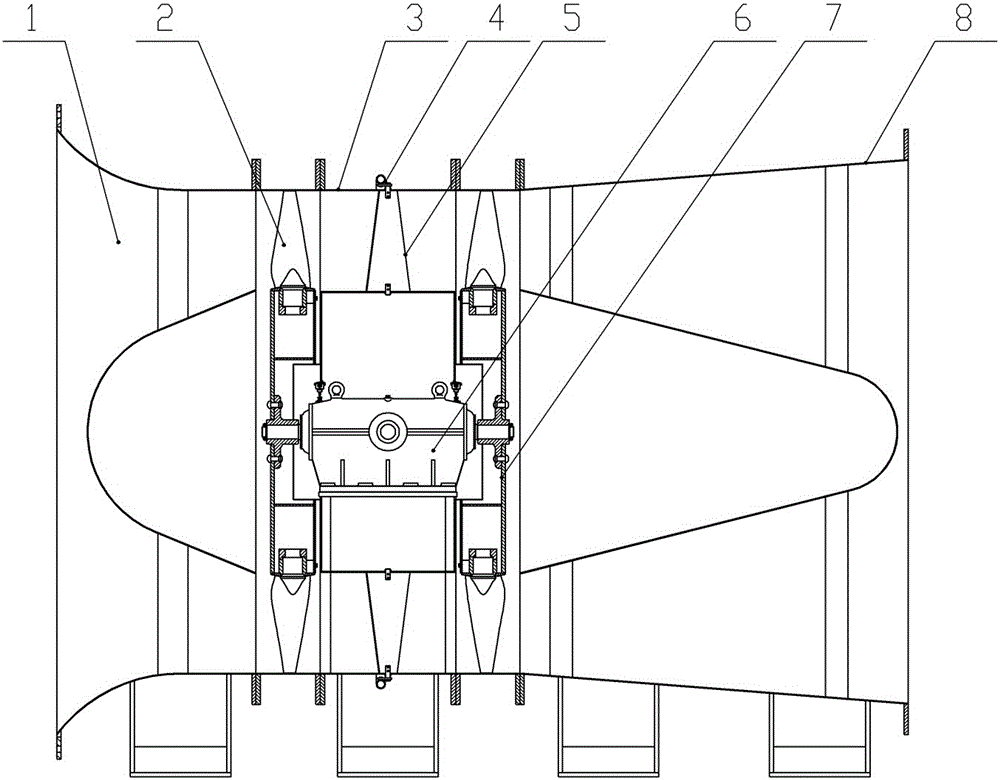

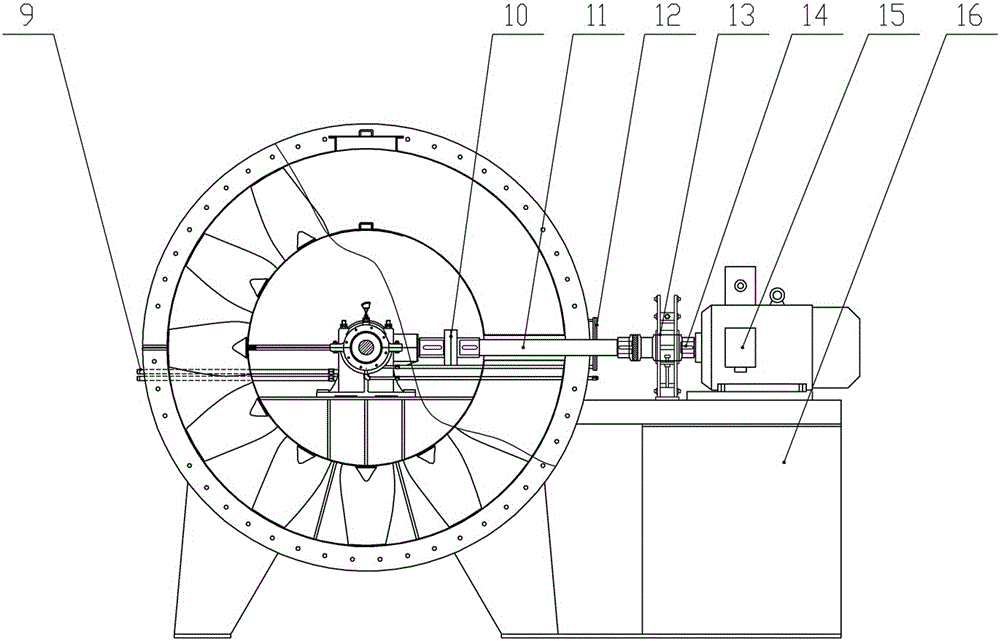

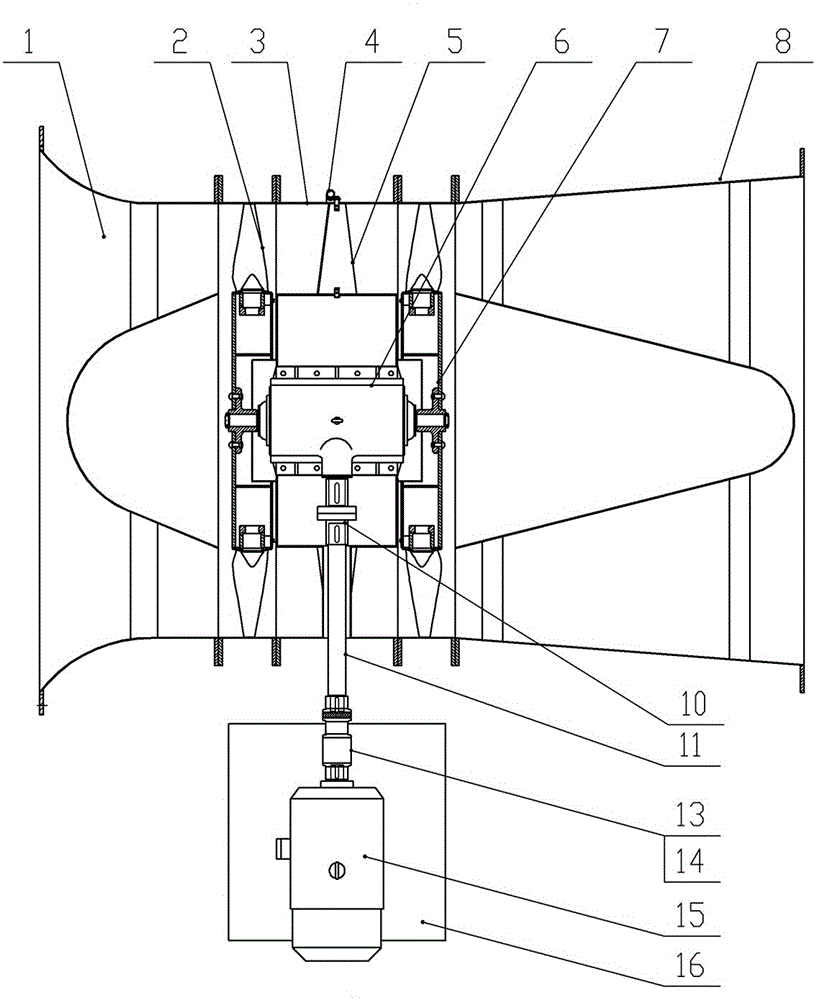

[0030] Embodiment 1, the present invention provides a motor lateral external one-to-two counter-rotating axial flow fan, which is characterized in that it includes a front impeller 2, a main engine cylinder 3, a guide vane adjustment mechanism 4, and a guide vane 5. Transmission box 6, rear impeller 7, internal coupling (10), transmission shaft 11, external coupling 14, motor 15 and motor support 16, main engine cylinder 3 includes outer cylinder and inner cylinder, inner and outer The annular space between the cylinders is the flow channel of the gas, and there are end plates at both ends of the inner cylinder to prevent or reduce harmful airflow entering the inner cylinder and affecting the transmission box. The transmission box 6 is installed on the machine base in the inner cylinder of the main engine cylinder body 3, the front impeller 2 and the rear impeller 7 are fixedly installed on the two output shafts of the transmission box 6, and guide vanes are arranged in the ann...

Embodiment 2

[0031] Embodiment 2, the front of the host cylinder 3 is provided with a current collector 1 to improve the efficiency of the fan, and the rear is provided with a sound-absorbing diffusion cylinder 8 to reduce the impact of noise. refer to Figure 1 to Figure 6 , all the other are with embodiment 1.

Embodiment 3

[0032]Embodiment 3, the transmission box 6 adopts a box-type structure, including an upper housing 601, a temperature sensor 602, a lower housing 603, a cooling water interface 604, a lubricating oil inlet and outlet interface 605, an output shaft 606, a gland 607, and an oil seal 608 , bearing 609, driven bevel gear 610, lock nut 611, driving bevel gear 612 and input shaft 613, an oil storage cavity, a cooling water interface 604 and a lubricating oil inlet and outlet interface 605 are arranged in the transmission box 6, and the oil storage cavity It does not communicate with the cooling water channel. The transmission box housing is composed of an upper housing 601 and a lower housing 603. The lower housing 603 acts as a support and oil storage. There are two output shafts 606 in the middle of the housing. The output shaft 606 and the bearing 609, the outer side of the bearing 609 is equipped with an oil seal 608 and a gland 607, the output shaft 606 and the input shaft 613 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com