Production process of low temperature phase change cold accumulation ice box or ice bag

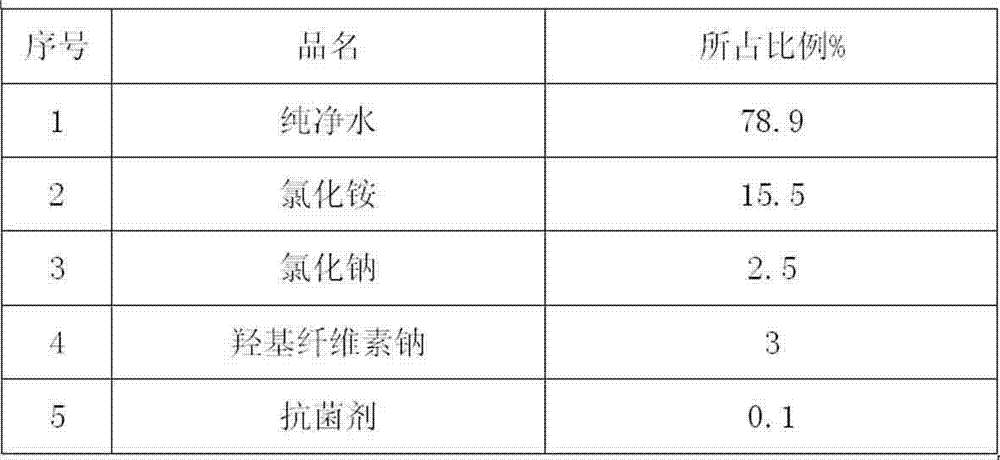

A low-temperature phase change and production process technology, which is used in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of inability to achieve cold storage effect, short low temperature maintenance time, reaching minus 13 degrees, and achieve good flatness. , The effect of reducing the cold storage space and reducing the cold storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The substantive content of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments:

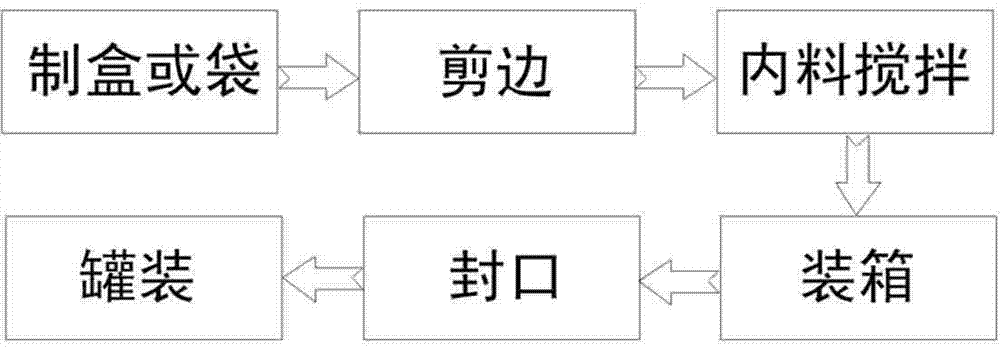

[0026] like figure 1 Shown: A production process of low-temperature phase-change cold storage ice boxes or ice packs. The process is implemented in six steps: box or bag making, trimming or trimming, internal material stirring, filling, sealing and boxing:

[0027] The first step is to make bags. Install the pre-designed mold in the shape of an ice bag on a high-frequency machine or a heat-sealing machine, and weld the upper and lower layers of plastic cloth or plastic composite cloth together to form a surrounding bag, and reserve a filling port; The mold in the shape of an ice box is installed on a blow molding machine or a plastic machine for blow molding or injection molding, and an enclosed ice box is made, and a filling port is reserved;

[0028] The second step is to cut the edges. For ice packs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com