Intelligent monitoring system for vibrating device

A technology of vibration equipment and intelligent monitoring, applied in the direction of measuring devices, comprehensive factory control, instruments, etc., can solve problems such as lack of remote transmission, database storage, analysis and processing, and fault judgment, failure to meet the requirements of vibration equipment, and single function. Achieve the effect of simple and intuitive remote monitoring operation interface, improve production management level, and high transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

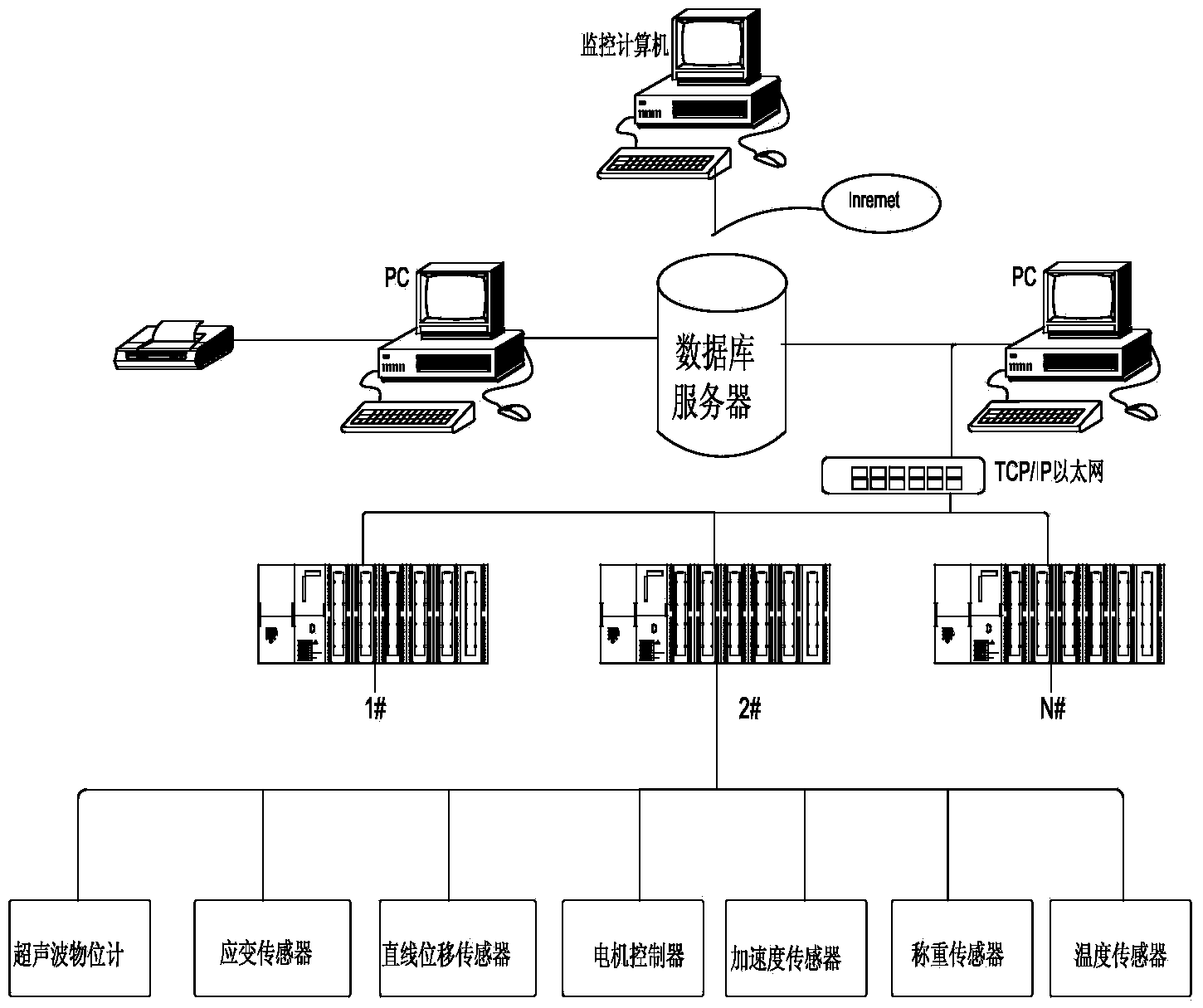

[0028] As shown in Figure 1, comprise data transmission device and data acquisition device, set data acquisition device on vibration equipment, the output end of data acquisition device connects database server by data transmission device, and database server connects monitoring computer by remote network; Data acquisition device Including ultrasonic level gauge, strain sensor, linear displacement sensor, motor controller, acceleration sensor, load cell and temperature sensor, respectively set on the vibration equipment, collect vibration equipment parameters, and then input the data transmission device to the database server for storage, Analysis and processing; database analysis and processing is to perform data analysis, calculation, judgment and alarm on the parameters of the vibration equipment, and to give early warning before the failure occurs. The data is released through the network and remotely monitored through the monitoring computer.

[0029] The data collected on...

Embodiment 2

[0034] On the basis of Embodiment 1, there are four linear displacement sensors, which are respectively installed at the four support points of the support base of the vibrating equipment to monitor the displacement between the vibration equipment and the support base during operation.

[0035] The strain sensors are respectively arranged on the excitation beam, beam, side plate and spring support of the vibration equipment to monitor the mechanical changes.

[0036] Load cells are respectively arranged at the bottom of the four support bases to monitor the change of the weight of the vibrating equipment.

[0037] Acceleration sensors are respectively arranged at the four corners of the vibration equipment to monitor the acceleration generated during vibration.

Embodiment 3

[0039] On the basis of Embodiment 1 or 2, the data transmission adopts wired transmission; the data transmission is carried out through shielded cables from the on-site measurement of electrical components 4-20ma, 0-10V, resistance signals and the PLC control system of the control cabinet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com