An intelligent control system and method for chassis temperature

An intelligent control system and chassis technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of controlling fan speed, damage to heating elements, waste of electric energy, etc., to improve temperature control accuracy and reduce usage Consumption, the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

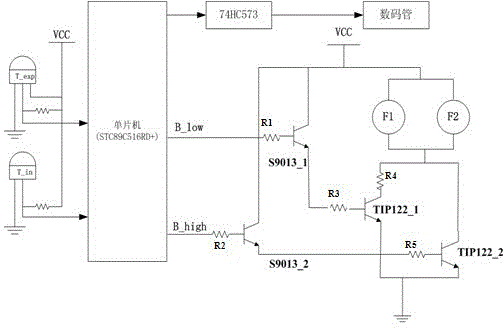

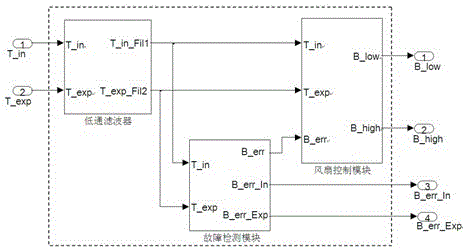

Method used

Image

Examples

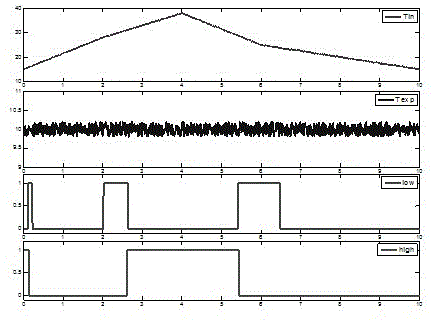

Embodiment 1

[0049] Taking the ambient temperature T_exp=10 degrees Celsius detected by the ambient temperature sensor outside the chassis as an example, an example of controlling the temperature of the chassis through the scheme of the present invention is given below. First compare the attached figure 2 The fan operating temperature lookup table shown in the table shows the standard temperature value T1=24°C in the chassis with the fan turned off, T2=28°C in the chassis with the fan turned on at low speed, and T3 in the chassis with the fan turned off at high speed =29°C, and the standard temperature in the chassis with the fan turned on at high speed T4=31°C. Then when the temperature value T_in in the chassis sensed by the chassis temperature sensor exceeds 28 degrees, the microcontroller outputs a control signal B_low=1, B_high=0 to control the fan to rotate at a low speed. If the temperature continues to rise to 31 degrees, the microcontroller outputs a control signal B_low=0 , B_h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com