Pixel unit, pixel circuit and driving method thereof

A pixel unit and pixel circuit technology, applied in static indicators, instruments, etc., can solve the problems of drive current difference, display brightness difference, threshold voltage drift, etc., to prolong service life, shorten stress time, and reduce misoperation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

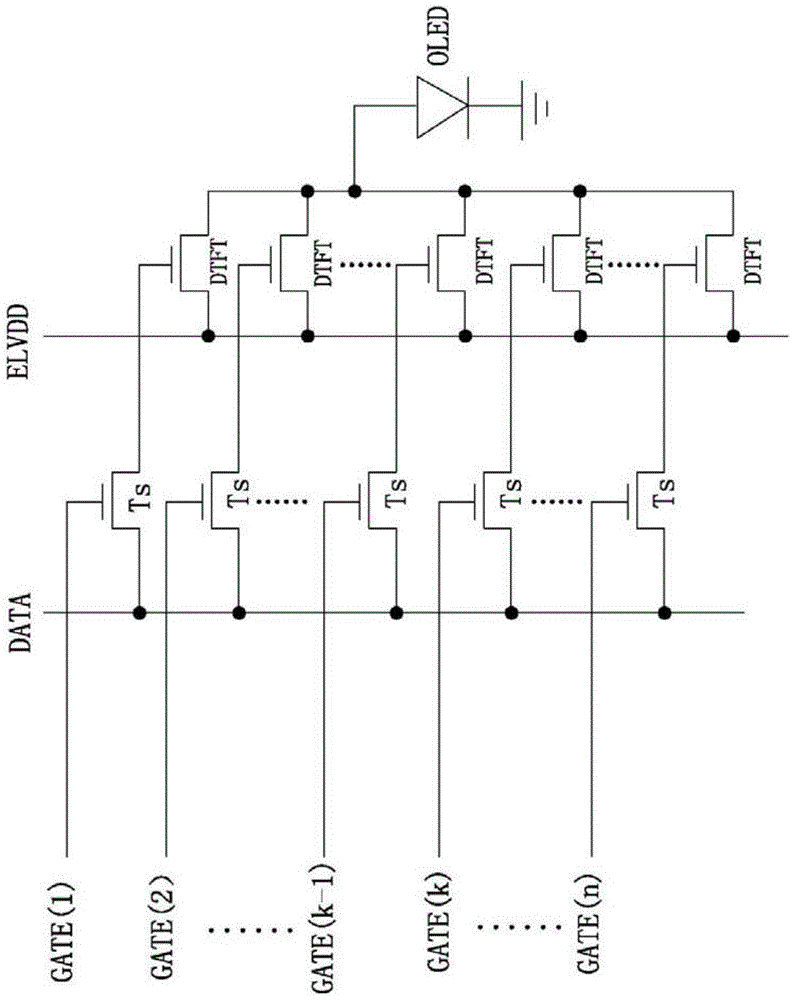

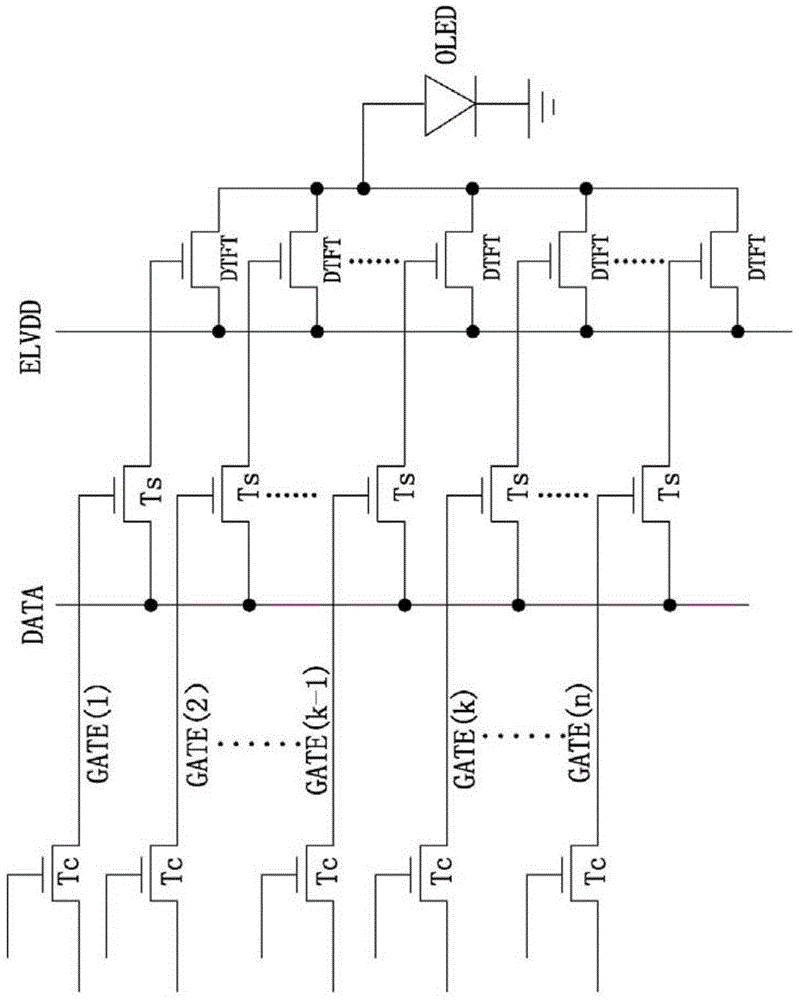

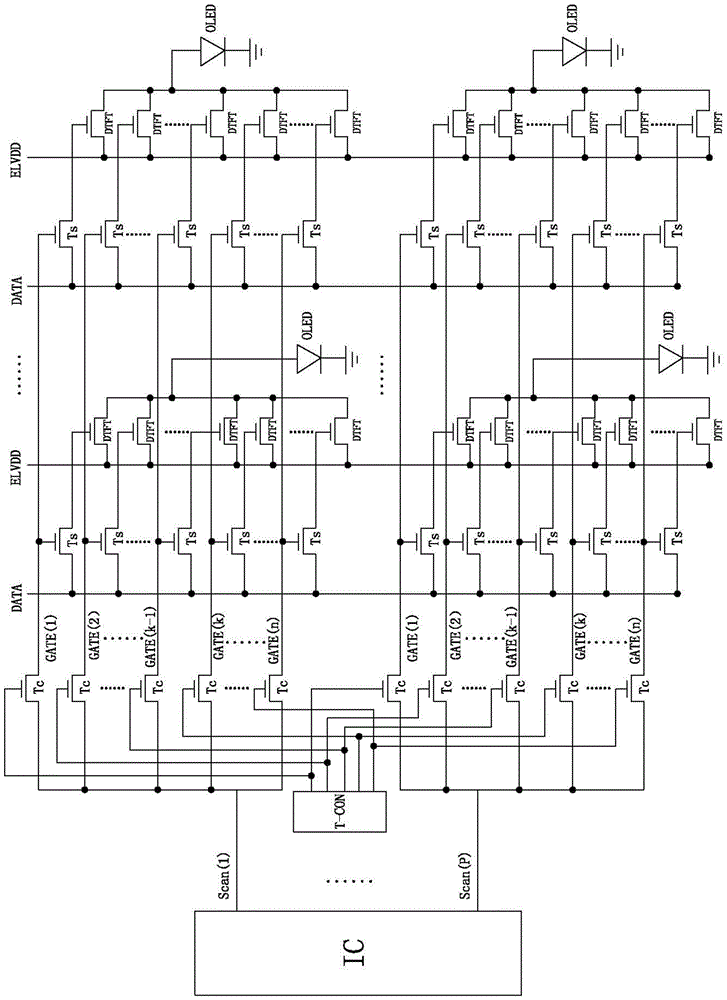

[0038] see figure 1 As shown, the pixel unit described in the embodiment of the present invention is mainly used for driving each light-emitting device in an active matrix organic light-emitting diode display, and each light-emitting device is driven by a pixel unit; each pixel unit includes a light-emitting device and n driving Sub-circuit; wherein, n is the number of driving sub-circuits, and n is a natural number, n>1;

[0039] Each of the driving sub-circuits includes a control electrode scanning signal line GATE, a switching transistor Ts and a driving transistor DTFT; the control electrode of the switching transistor is connected to the control electrode scanning signal line, the first pole is connected to the data line DATA, and the second pole is connected to the control electrode scanning signal line. connected to the control pole of the driving transistor; the first pole of the driving transistor is connected to the power supply line ELVDD, and the second pole is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com