Photovoltaic power generation system based on MOSFET (metal-oxide-semiconductor field effect transistor) counter-current prevention

A photovoltaic power generation system, photovoltaic cell panel technology, applied in photovoltaic power generation, electrical components, output power conversion devices, etc., can solve the problems of power consumption, reduce the mechanical strength of photovoltaic power generation systems, increase system volume and weight, etc. The effect of internal loss, ensuring energy utilization efficiency, and improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

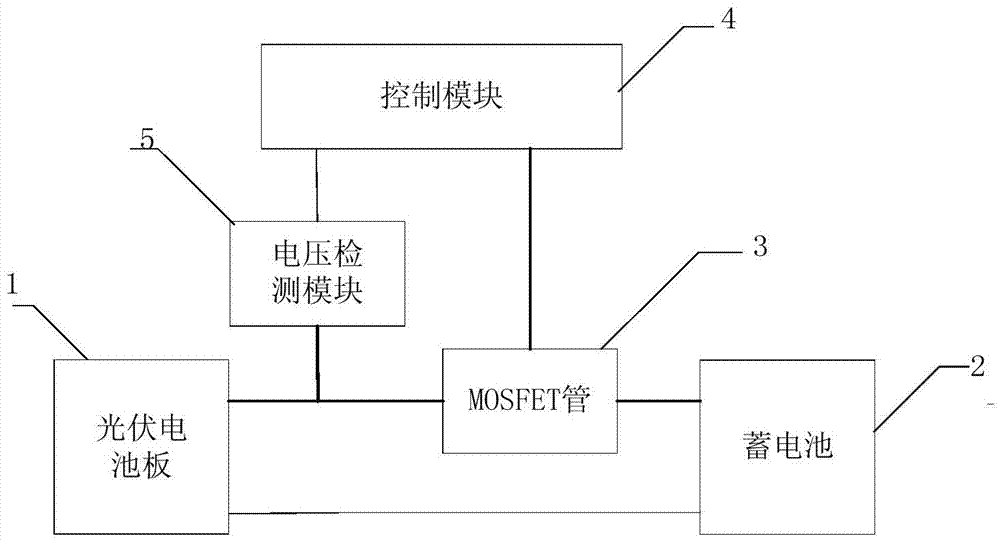

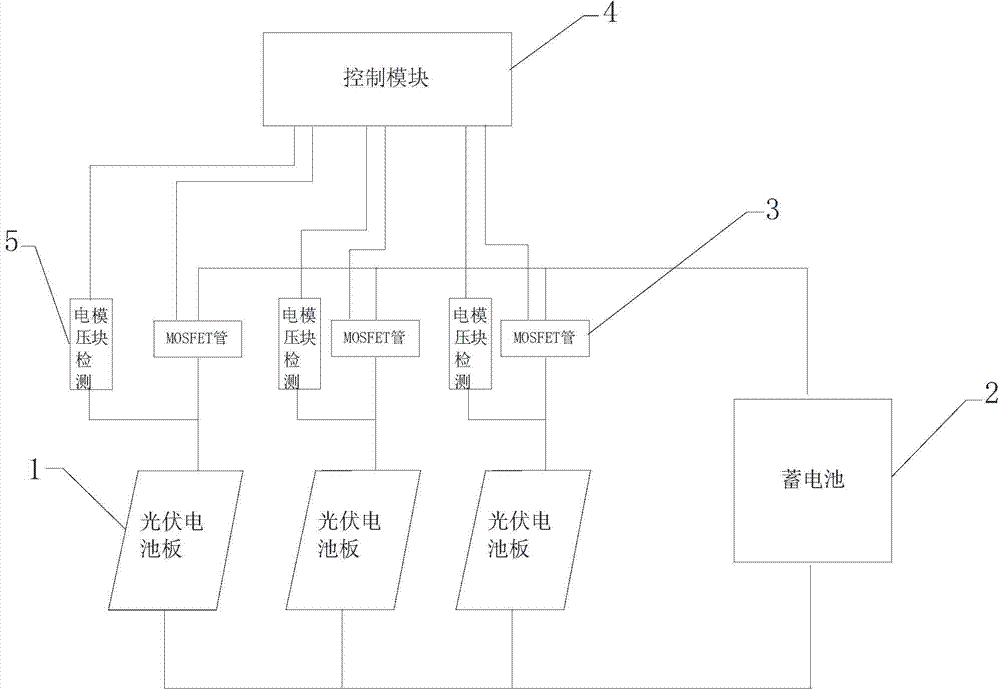

[0019] The MOSFET tube described in this application document is: Metal-Oxide-Semiconductor-Field-Effect Transistor, referred to as Metal-Oxide-Semiconductor Field-Effect Transistor, and its full name in English (Metal-Oxide-Semiconductor Field-Effect Transistor, MOSFET). In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0020] figure 2 and image 3 It is a block diagram of two embodiments of the photovoltaic power generation system based on MOSFET tube backflow prevention in the present invention. The photovoltaic power generation system based on MOSFET anti-backflow includes a storage battery 2 and at least one photovoltaic panel 1, and also includes a control module 4, at least one voltage detection module 5 and at least one MOSFET tube 3; There is only one MOSFET tube 3 connected between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com