Electromagnetic heating coffee machine and method for making coffee

A coffee machine and heating technology, which is applied in the field of electromagnetic heating coffee machine and coffee making, can solve the problems of non-existence and single function, and achieve the effect of multiple functions and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

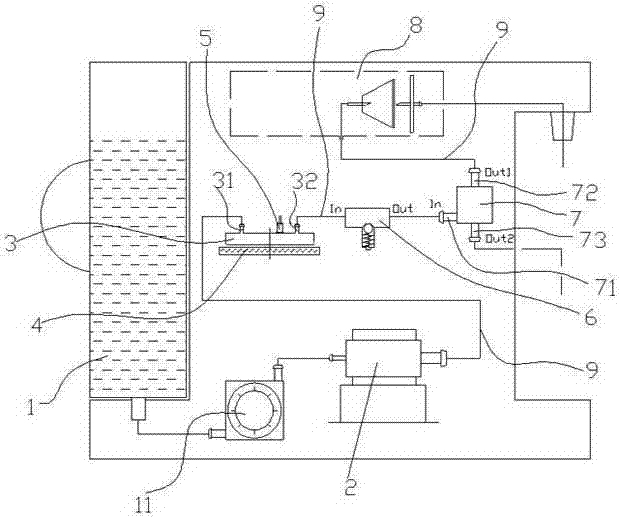

[0034] Such as figure 1 As shown, an embodiment of an electromagnetic heating coffee machine in the present invention includes a water storage tank 1, a heating assembly, a coffee brewing core 8 and a control circuit board (not shown in the figure) for controlling the operation of the coffee machine. The water storage tank 1, The heating assembly and the coffee brewing core 8 are sequentially connected by a delivery pipe 9;

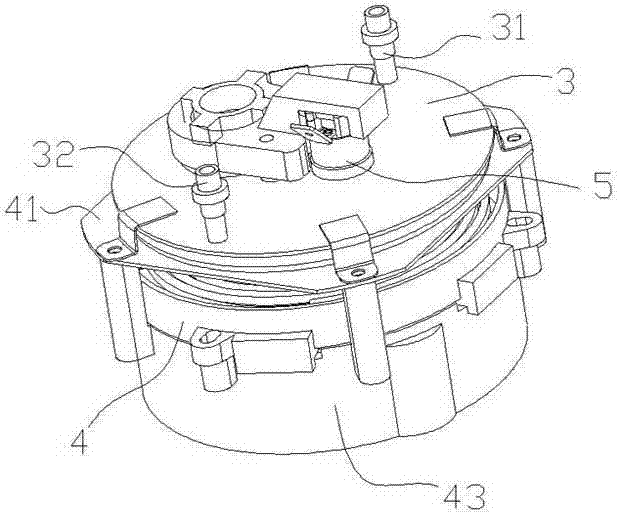

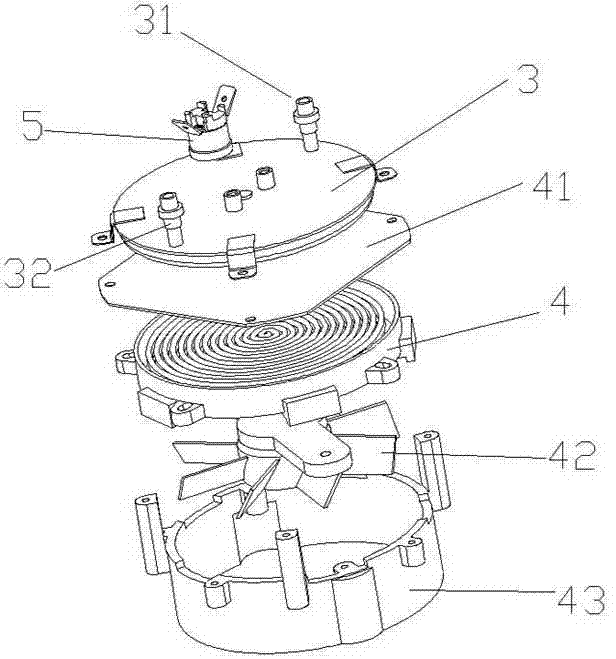

[0035] Such as figure 1 and figure 2 As shown, the heating assembly includes a boiler 3 and an electromagnetic coil 4 located directly below the bottom surface of the boiler 3. The boiler 3 is induced by the electromagnetic coil 4 to generate eddy current heating at the bottom of the boiler. The boiler 3 is a closed boiler, and the boiler 3 An inlet port 31 and an outlet port 32 are provided, and the inlet port 31 and the outlet port 32 are airtightly connected to the delivery pipe 9 respectively, and a water pump 2 is also provided between the water s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com