Treatment technology for Claus tail gas containing sulfur dioxide, hydrogen sulfide and organic sulfur

A Claus tail gas, sulfur dioxide technology, applied in the preparation/purification of sulfur, chemical instruments and methods, separation of dispersed particles, etc., can solve the problems of large investment, complex process, high energy consumption, and achieve low investment and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

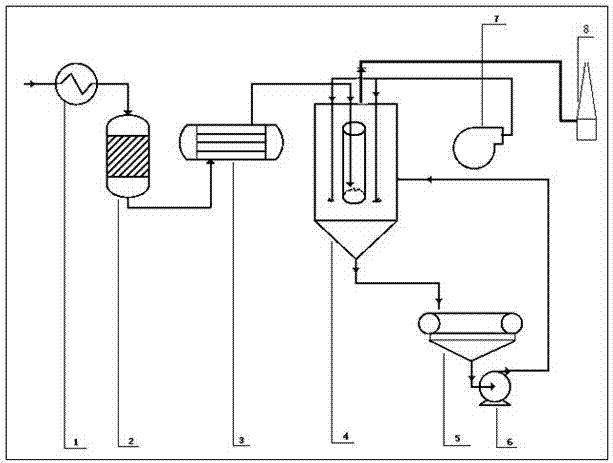

Embodiment 1

[0039] Example 1: Heat the Claus tail gas to 210°C through the heat exchanger 1, and then pass it into the hydrogenation reactor 2 according to the ratio of the sulfur content in the tail gas to the hydrogen molar ratio of 1:1.1, and the hydrogenation reactor 2 has Low-temperature hydrogenation catalyst, the gas temperature after hydrogenation reaches above 260°C, the gas is cooled to 50°C through the fourth stage of the cooler 3, and then the gas enters the complex iron liquid phase redox desulfurizer 4, and simultaneously flows to the complex iron liquid Compressed air is fed into the phase redox desulfurizer 4 . The temperature inside the complex iron liquid-phase redox desulfurizer 4 is 15°C, hydrogen sulfide is converted into sulfur, the sulfur settles in the complex iron liquid-phase redox desulfurizer 4 and is filtered through the sulfur filter 5, and the supernatant is centrifuged The pump 6 returns to the complex iron liquid phase redox desulfurizer 4, and the tail ga...

Embodiment 2

[0040] Example 2: Heat the Claus tail gas to 280°C through the heat exchanger 1, and then pass it into the hydrogenation reactor 2 according to the ratio of the sulfur content in the tail gas to the hydrogen molar ratio of 1:1.1, and the temperature after the reaction is 310°C. This gas is cooled to 80°C by four stages of cooler 3, and then the cooled gas is directly passed into the complex iron liquid phase redox desulfurizer 4, and at the same time, it is passed into the complex iron liquid phase redox desulfurizer 4 compressed air. The temperature inside the complex iron liquid-phase redox desulfurizer 4 is 60° C., hydrogen sulfide is converted into sulfur, and the sulfur settles in the complex iron liquid-phase redox desulfurizer 4 and is filtered through the sulfur filter 5 . The supernatant is returned to the complex iron liquid phase redox desulfurizer 4 through the centrifugal pump 6, and the tail gas is directly discharged through the tail gas chimney 8. The hydrogen...

Embodiment 3

[0041] Example 3: Heat the Claus tail gas to 235°C through the heat exchanger 1, and then pass it into the hydrogenation reactor 2 according to the ratio of the sulfur content in the tail gas to the hydrogen molar ratio of 1:1.1, and the temperature after the reaction is 273°C; This gas flow is cooled to 65° C. through the cooler 3, and then directly enters the complex iron liquid-phase redox desulfurizer 4, and at the same time, compressed air is fed into the complex iron liquid-phase redox desulfurizer 4. The temperature inside the complex iron liquid-phase redox desulfurizer 4 is 50° C., hydrogen sulfide is converted into sulfur, and the sulfur settles in the complex iron liquid-phase redox desulfurizer 4 and is filtered through the sulfur filter 5 . The supernatant is returned to the complex iron liquid phase redox desulfurizer 4 through the centrifugal pump 6, and the tail gas is directly discharged through the tail gas chimney 8. The sulfur content of the treated tail ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com