Metal and alloy hollow powder preparing method

A hollow powder and alloy technology, applied in the field of hollow powder manufacturing, can solve the problems of oxidation phenomenon, weak reactivity, long reaction time, etc., and achieve the effects of wide application range, increased product volume, and less evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

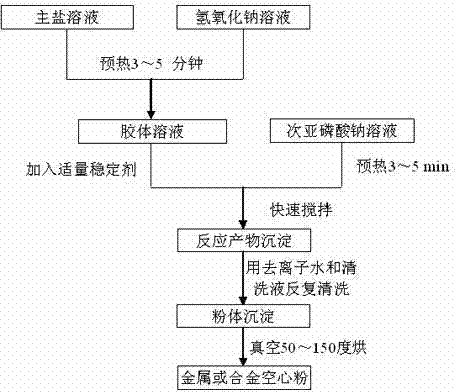

[0015] The invention provides a method for preparing metal and alloy hollow powder, which comprises the following steps. Dissolve an appropriate amount of main salt, sodium hypophosphite and sodium hydroxide in deionized water to prepare a 50-200ml solution. The concentration of the main salt solution is 0.2-1.0 mol / L, and the concentration of the sodium hypophosphite solution is 0.3 ~3.0 mol / L, the concentration of sodium hydroxide solution is 0.5~3.0 mol / L, the main salt is the sulfate or chloride salt corresponding to the hollow powder material to be prepared, and the main salt is a single metal salt or multiple metal salts mixture. Sodium hydroxide (NaOH) and sodium hypophosphite (NaH 2 PO 2 ·H 2 O) as alkali and reducing agent in the preparation method respectively. The raw materials used are of analytical grade.

[0016] In a specific embodiment, the main salt can be sulfate of cobalt, chloride of cobalt, sulfate of nickel, chloride of nickel, sulfate of iron, chlor...

Embodiment 1

[0027] Embodiment one: prepare single metal hollow powder

[0028] Nickel sulfate or chloride is used as the main salt.

[0029] (1) Dissolve an appropriate amount of main salt, sodium hypophosphite and sodium hydroxide in deionized water, and prepare a 200ml solution in a beaker. The concentration of the main salt solution is 0.5 mol / L, and the concentration of the sodium hypophosphite solution is 1.0 mol / L, the concentration of sodium hydroxide solution is 0.8 mol / L;

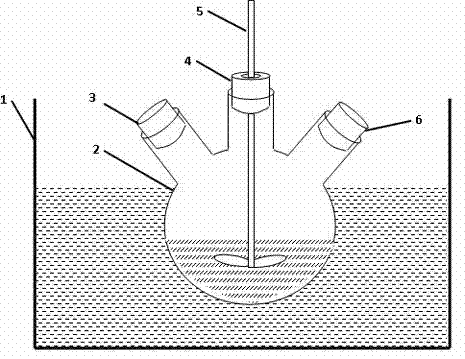

[0030](2) Pour the main salt solution into a three-necked flask from one mouth, put the three-necked flask into an oil bath at 80°C for preheating, and put the other two solutions into the same oil bath for preheating, and the preheating time is 5 minutes ;

[0031] (3) Slowly pour the sodium hydroxide solution into a three-necked flask from one side, and simultaneously use a mechanical stirring rod to stir at a speed of 800 rpm for 5 minutes;

[0032] (4) Add appropriate amount of stabilizer to prevent col...

Embodiment 2

[0036] Embodiment 2: Preparation of cobalt metal hollow powder.

[0037] Cobalt sulfate is used as the main salt.

[0038] (1) Dissolve an appropriate amount of main salt, sodium hypophosphite and sodium hydroxide in deionized water, and prepare a 50ml solution in a beaker. The concentration of the main salt solution is 1 mol / L, and the concentration of the sodium hypophosphite solution is 3.0 mol / L, the concentration of sodium hydroxide solution is 3 mol / L;

[0039] (2) Pour the main salt solution into a three-necked flask from one mouth, put the three-necked flask into an oil bath at 120°C for preheating, and put the other two solutions into the same oil bath for preheating, and the preheating time is 5 minutes ;

[0040] (3) Slowly pour the sodium hydroxide solution into the three-necked flask from one side, and simultaneously use a mechanical stirring rod to stir at a speed of 800 rpm for 10 minutes;

[0041] (4) Add appropriate amount of stabilizer to prevent colloidal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com