Compensation type integrated-motor electronic control brake system

A technology that integrates motors and electronically controlled brakes. It is applied in the direction of brakes, brake transmissions, transportation and packaging, etc. It can solve the problems of slow system response, difficult matching technology, and vacuum degree dependence, so as to ensure safe and reliable operation. , The matching design is flexible and convenient, and the effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

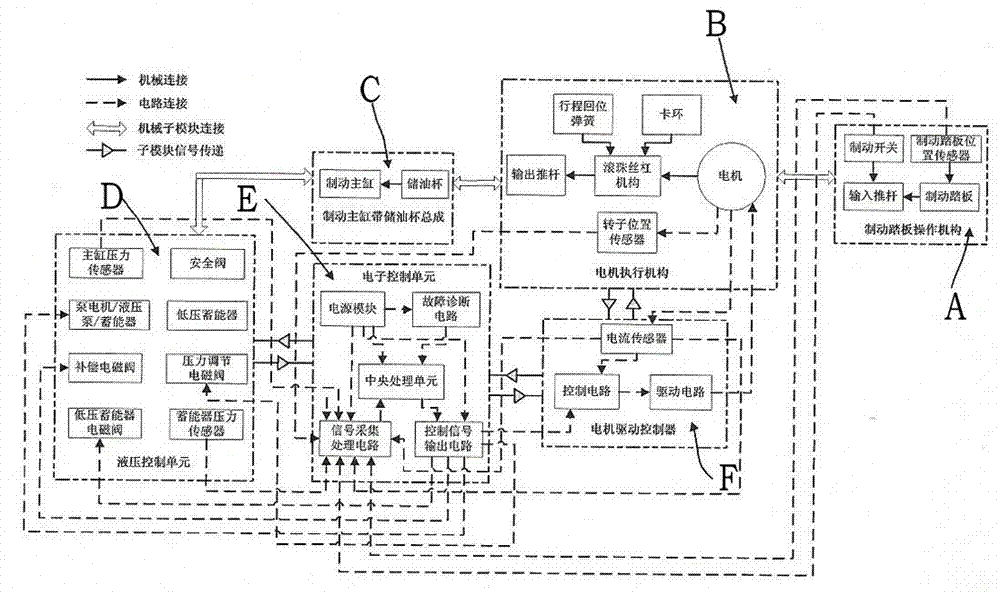

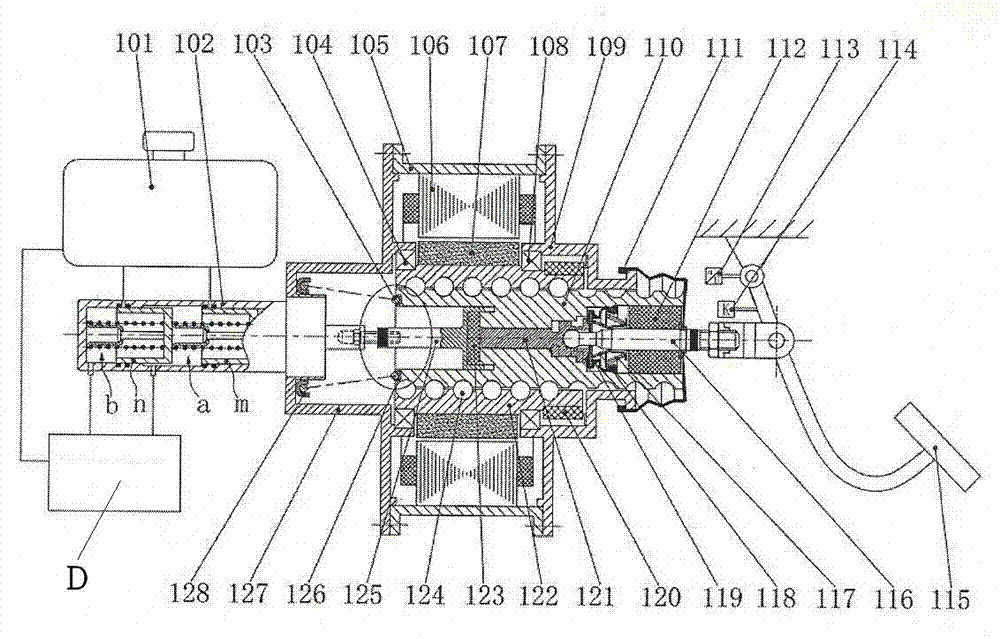

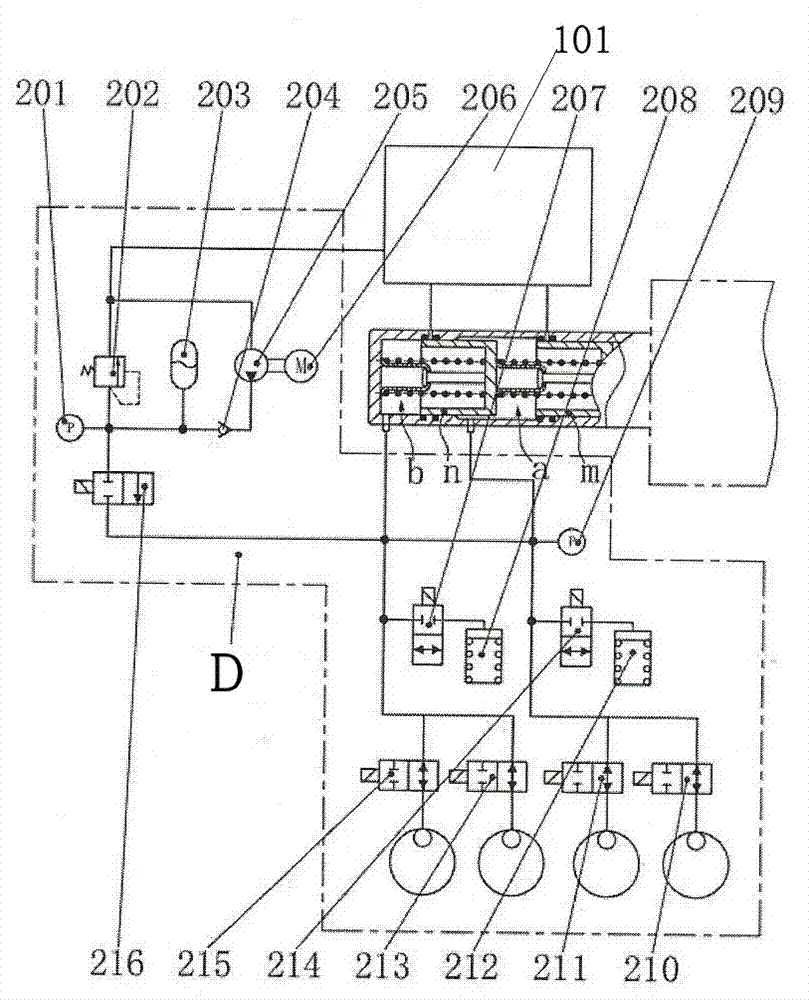

[0029] see Figure 1 to Figure 8As shown, the present invention is composed of a brake pedal operating mechanism A, a motor actuator B, a brake master cylinder with an oil storage cup assembly C, a hydraulic control unit D, an electronic control unit E and a motor drive controller F. Pedal operating mechanism A is connected to motor actuator B, motor actuator B is connected to brake master cylinder with oil storage cup assembly C, hydraulic control unit D is respectively connected to brake master cylinder with oil storage cup assembly C and each circuit The moving wheel cylinder is mechanically connected through hydraulic oil pipes and joints, the electronic control unit E is respectively connected to the hydraulic control unit D and the motor drive controller F circuit, and the motor drive controller F is connected to the motor actuator B circuit;

[0030] The brake pedal 115 of the brake pedal operating mechanism A is respectively connected to the brake switch 114, the brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com