High-temperature preparation device of bamboo fiber nano-carbon particles

A technology of nano carbon particles and bamboo fibrils, applied in nano carbon and other directions, can solve the problems of complex process, high fuel consumption, pollution and other problems, and achieve the effects of strong chemical reactivity, optimized dispersion and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

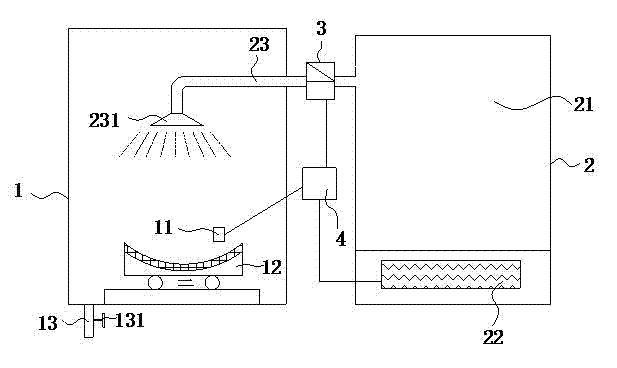

[0013] refer to figure 1 , a high-temperature preparation device of bamboo fiber nano-carbon particles, including a closed container 1 with a built-in temperature sensor 11 and a vibrator 12 and a high-temperature steam generator 2, and the high-temperature steam generator 2 includes a water tank 21 for heating An electric heater 22 for water and a steam output pipeline 23, the steam output pipeline 23 communicates with the upper cavity of the airtight container 1, the steam output pipeline 23 is provided with a solenoid valve 3, the temperature sensor 11 is connected to the industrial control The input terminal of the computer 4 is connected, and the industrial computer 4 controls the electric heater 22 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com