Preparation method of metal lithium negative electrode with hydrophobic protective layer

A hydrophobic protective layer, metal lithium technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of unstable metal lithium negative electrodes, large interface impedance between metal lithium negative electrodes and solid electrolytes, and lithium dendrites. Achieve the effect of reducing production and R&D costs, solving large interface resistance, and enhancing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a metal lithium negative electrode with a hydrophobic protective layer, comprising the following steps:

[0037] Step 1. 1g magnesium stearate and 0.5g polyethylene oxide are mixed to obtain a hydrophobic mixture.

[0038] Step 2. Dissolve the hydrophobic mixture in 25 mL of N-methylpyrrolidone solvent, heat and stir, set the heating temperature to 55° C., and set the stirring speed to 900 r / min until the hydrophobic mixture is completely dissolved to obtain a protective solution.

[0039] Step 3. Spin-coat the protective solution on both surfaces of the ultra-thin metal lithium sheet in dry argon. The spin coating speed was 600 r / min, and the spin coating lasted 60 s. After heating and curing, the heating temperature is 55°C for 30 minutes. A metal lithium negative electrode with a hydrophobic protective layer on both surfaces was obtained, and the thickness of the single-sided hydrophobic protective layer was 5 μm.

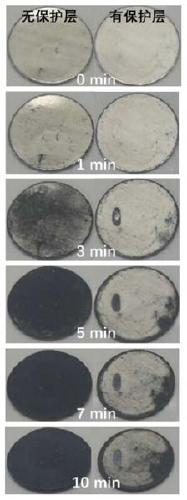

[0040] Stability test in ...

Embodiment 2

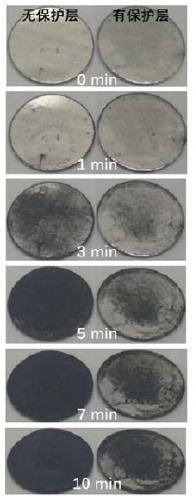

[0044] A preparation method of a metal lithium negative electrode with a hydrophobic protective layer, weighing 1g magnesium stearate and 0.5g polyvinylidene fluoride-hexafluoropropylene, using 25mL N-methylpyrrolidone solvent as a solvent, and proceeding according to the method in Example 1 Stirring and spin coating to prepare a metal lithium negative electrode with a hydrophobic protective layer on both surfaces, and the thickness of the hydrophobic protective layer on one side is 5 μm.

[0045] Stability test in air according to the method of embodiment 1, the results are shown in the appendix figure 2 , it can be seen that the metal lithium sheet obtained by the method of Example 2 can be placed stably in humid air for 1 min.

[0046] The impedance test was carried out according to the method of Example 1. The impedance of the lithium metal sheet treated by the method of Example 2 was 75 ohms, and the impedance of the lithium metal sheet obtained by coating polyvinylidene...

Embodiment 3

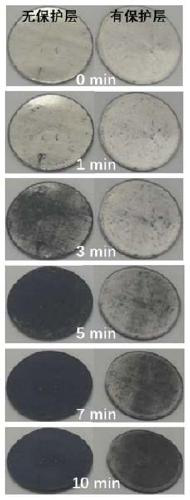

[0049] A preparation method of a metal lithium negative electrode with a hydrophobic protective layer, taking 1g magnesium stearate and 0.5g polydimethylsiloxane, using 25mL n-hexane as a solvent, stirring and spin coating according to the method in Example 1, A metal lithium negative electrode with a hydrophobic protective layer on both surfaces was prepared, and the thickness of the single-sided hydrophobic protective layer was 5 μm.

[0050] Stability test in air according to the method of embodiment 1, the results are shown in the appendix image 3 , it can be seen that the metal lithium sheet obtained by the method of Example 3 can be placed stably in humid air for 5 min.

[0051] The impedance test was carried out according to the method of Example 1, and the impedance of the metal lithium sheet obtained by the method of Example 3 was 120 ohms.

[0052] The charging and discharging test was carried out according to the method of Example 1. The battery assembled from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com