Preparation method of weather-resistant titanium dioxide

A technology of titanium dioxide and weather resistance, applied in the field of pigments, can solve problems such as poor weather resistance, and achieve the effect of improving product whiteness and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

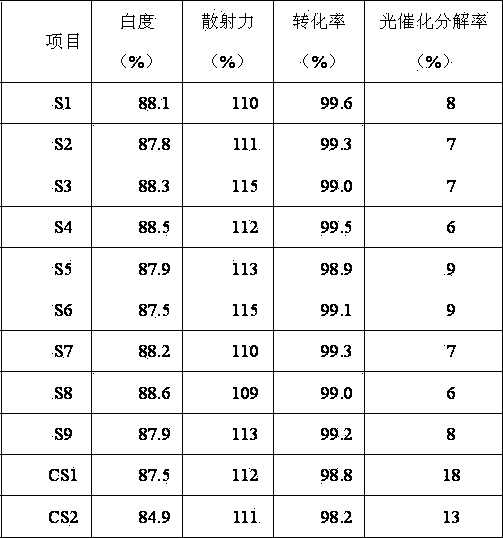

Examples

preparation example Construction

[0022] The invention provides a preparation method of weather-resistant titanium dioxide, the method comprising the following steps:

[0023] S1. The mineral is subjected to acid hydrolysis, sedimentation and filtration, crystallization to remove green vitriol, and concentration to obtain a concentrated titanium solution, which is then hydrolyzed and washed once with water to obtain a washed metatitanic acid slurry;

[0024] S2, bleaching the first-washed metatitanic acid slurry;

[0025] S3, washing the bleached metatitanic acid twice;

[0026] S4. Doping the metatitanic acid treated in step S3, the doping method is to add phosphorus compound, magnesium compound, antimony compound, aluminum compound, lithium compound, potassium compound to the metatitanic acid after secondary water washing in sequence aqueous solution, mixed uniformly;

[0027] S5, filtering and dehydrating the doped metatitanic acid, and then calcining to obtain crude titanium dioxide;

[0028] S6, pulver...

Embodiment 1

[0058] TiO 2 Put 400ml of once-washed metatitanic acid with a content of 280g / L in a 500ml beaker, add 10ml of 93% sulfuric acid under electric stirring, and add the acid for 15 minutes. After adding the acid, heat it with an electric furnace to keep the temperature of the slurry at 60°C. After reaching the above temperature, add Ti to the above metatitanic acid 3+ Concentration (as TiO 2 Total) is 3ml of 60 g / L trivalent titanium solution, the feeding time is 10min, and the Ti 3+ Then continue to stir for 20 minutes, stop stirring, and let it stand for aging for 1.0 hours.

[0059] Take 350ml of the above-mentioned bleached metatitanic acid, and vacuum filter it with a Buchner funnel. When about 1 / 3 of the solid surface is exposed, wash with 1000ml of deionized water with a temperature of 48°C, a pH value of 1.5, and a resistivity of 560Ω*m, then suck and dry to obtain a filter cake, and then use an appropriate amount of deionized water Mix with water to make slurry metati...

Embodiment 2

[0064] TiO 2 Put 400ml of once-washed metatitanic acid with a content of 300g / L in a 500ml beaker, add 10ml of 98% sulfuric acid under electric stirring, and add the acid for 15 minutes. After adding the acid, heat it with an electric furnace to keep the temperature of the slurry at 65°C. After reaching the above temperature, add Ti to the above metatitanic acid 3+ Concentration (as TiO 2 Total) is 5ml of 60 g / L trivalent titanium solution, the feeding time is 15min, and the Ti 3+ Then continue to stir for 20 minutes, stop stirring, and let it stand for aging for 1.0 hours.

[0065] Take 350ml of the above-mentioned bleached metatitanic acid, and vacuum filter it with a Buchner funnel. When about 1 / 3 of the solid surface is exposed, wash with 1000ml of deionized water with a temperature of 45°C and a resistivity of 500Ω*m to adjust the pH value to 1.0, then suction filter and dry to obtain a filter cake, and then use an appropriate amount of deionized water mixed with wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com