Lipopeptide modified nano zinc oxide as well as synthesis method and application thereof

A technology of nano-zinc oxide and a synthesis method, which is applied in the field of daily chemical materials, can solve the problems of poor biocompatibility of surface modifiers, low modification efficiency, complex surface modification methods, etc., and achieves low photochemical activity and high biological phase. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for synthesizing a lipopeptide-modified nano-zinc oxide of the present embodiment, comprising the following steps:

[0035] (1) Add 100 mL of deionized water to a 250 mL four-necked flask equipped with a stirring paddle and a thermometer, then add 4.4 g of zinc acetate dihydrate and continue stirring for 30 min to obtain a zinc salt solution and heat up to 60°C.

[0036] (2) Dissolve lipopeptide and sodium hydroxide in water, prepare lipopeptide (80 mg / L)-sodium hydroxide solution (0.4 mol / L), and raise the temperature to 60°C.

[0037] (3) The lipopeptide-sodium hydroxide solution was added dropwise to the zinc salt solution until the pH was 10.5. After the reaction for 2 h, the product was filtered with a microporous membrane and washed with deionized water until neutral. The obtained powder was heated at 100 °C After drying for 24h, lipopeptide-modified nano-zinc oxide was obtained.

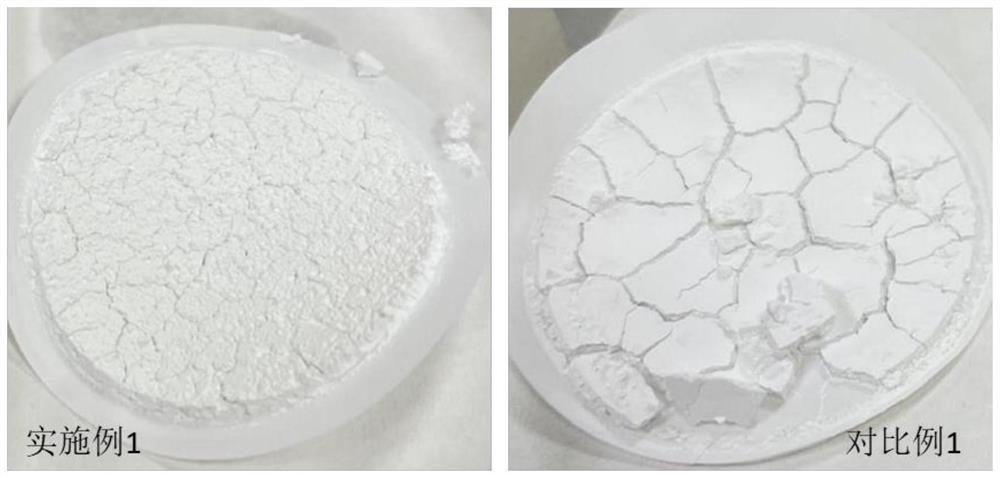

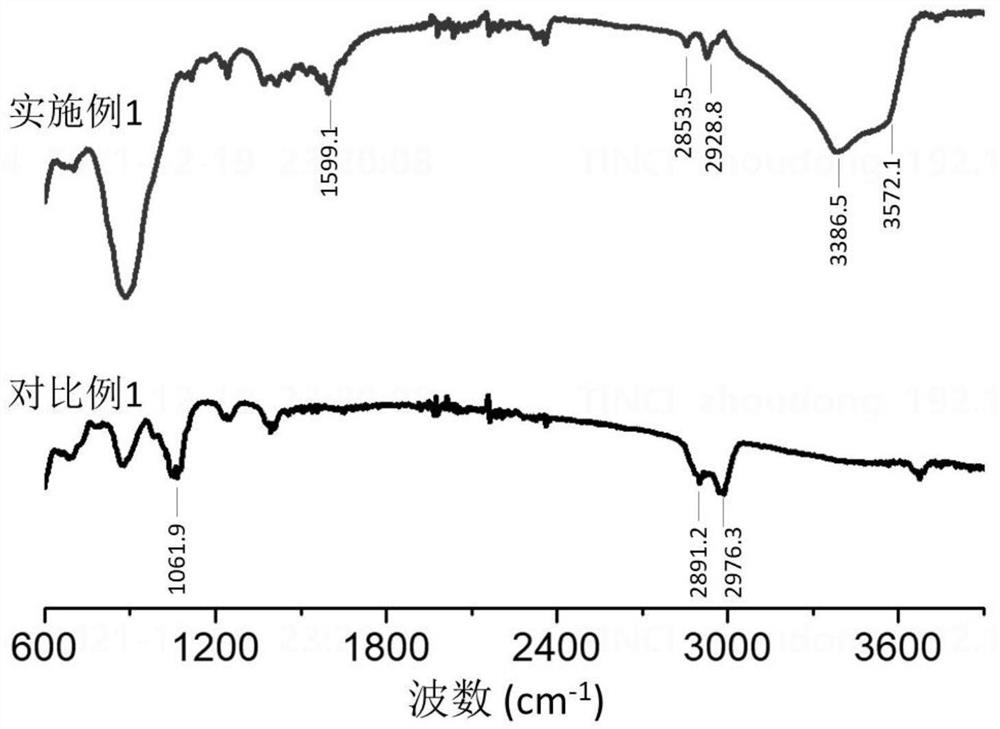

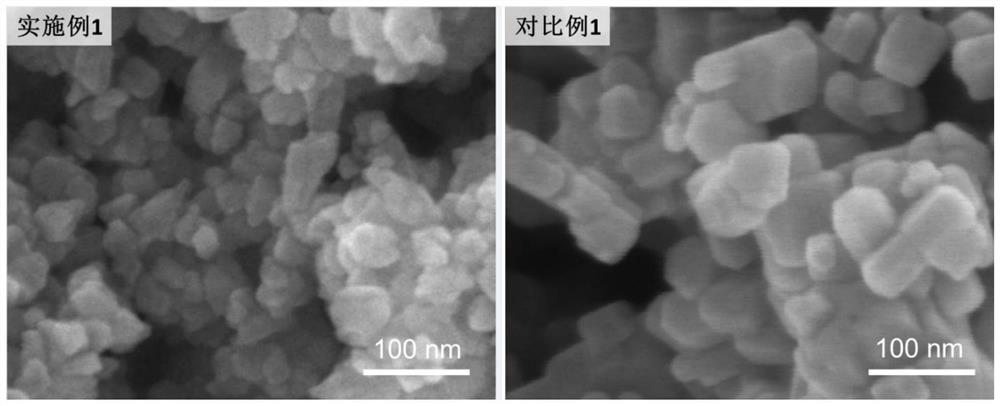

[0038] After the nano-zinc oxide formed in the solution is wrapped by lip...

Embodiment 2

[0040] A method for synthesizing a lipopeptide-modified nano-zinc oxide of the present embodiment, comprising the following steps:

[0041](1) Add 100 mL of deionized water to a 250 mL four-necked flask equipped with a stirring paddle and a thermometer, then add 2.7 g of zinc chloride and continue stirring for 30 min to obtain a zinc salt solution and heat up to 60°C.

[0042] (2) Dissolve lipopeptide and sodium hydroxide in water, prepare lipopeptide (80 mg / L)-sodium hydroxide solution (0.4 mol / L), and raise the temperature to 60°C.

[0043] (3) The lipopeptide-sodium hydroxide solution was added dropwise to the zinc salt solution until the pH was 10.5. After the reaction for 2 h, the product was filtered with a microporous membrane and washed with deionized water until neutral. The obtained powder was heated at 100 °C After drying for 24h, lipopeptide-modified nano-zinc oxide was obtained.

[0044] Infrared and SEM results showed that the synthesized nanoparticles were simi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com