Surface modifying method for biological material

A technology of surface modification and biomaterials, which is applied in medical science, surgery, coating, etc., can solve the problems of difficult to control surface properties, difficult to effectively control implant materials by surrounding tissues, and difficult to achieve various molecular biological activities. Improves biocompatibility and implant success, eliminates interactions, and improves performance and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

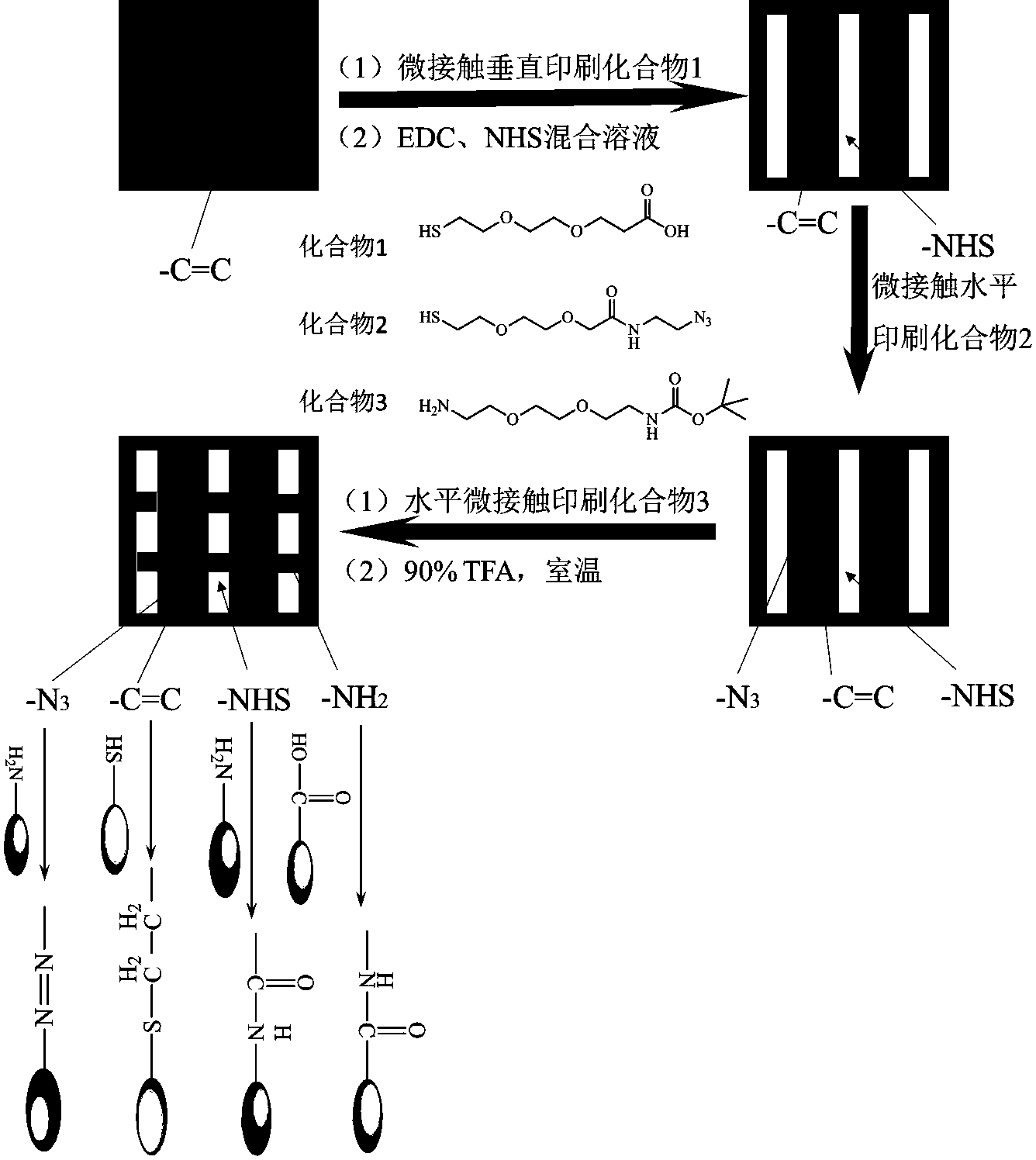

[0030] Example 1: Treat the surface of the material according to the following steps

[0031] (1) Surface activation and self-assembly: After the sample is fully cleaned, it is treated with oxygen plasma, the discharge power is 50W, and the treatment time is 5 minutes; the treated sample is immersed in a 5mM allyltrimethoxysilane ethanol solution for reaction After 6 hours, take it out, wash it thoroughly with ethanol and distilled water in turn, and dry it in the air.

[0032](2) Construction of multi-functional chemical surface: firstly, drop the ethanol mixed solution of compound 1 (20mM, 1ml) and DMPA (10mM, 1ml) onto the surface of the stamp, absorb for 1 minute, blow dry slowly with argon gas, and combine with the double bond The surface of the modified material is fully contacted, and the stamp is removed after irradiating with 365nm ultraviolet light for 1min, ultrasonically cleaned with ethanol solution, dried with Ar, and further immersed in the mixed solution of E...

Embodiment 2

[0034] Example 2: Treat the surface of the material according to the following steps

[0035] (1) Surface activation and self-assembly: After the sample is fully cleaned, it is treated with oxygen plasma, the discharge power is 150W, and the treatment time is 20 minutes; the treated sample is immersed in an ethanol solution of 5mM allyltriethoxysilane React for 12 hours, take it out, wash it thoroughly with ethanol and distilled water, and then dry it;

[0036] (2) Multi-functional chemical surface construction: First, drop the ethanol mixed solution of compound 1 (50mM, 1ml) and DMPA (25mM, 1ml) onto the surface of the stamp, absorb it for 2 minutes, blow dry it slowly with argon gas, and combine with the double bond The surface of the modified material is in full contact, and the stamp is removed after irradiating with 365nm ultraviolet light for 2 minutes, ultrasonically cleaned with ethanol solution and dried with Ar, and the substrate is further immersed in the mixed so...

Embodiment 3

[0038] Example 3: Treat the surface of the material according to the following steps

[0039] (1) Surface activation and self-assembly: After the sample is fully cleaned, it is treated with oxygen plasma, the discharge power is 300W, and the treatment time is 30 minutes; the treated sample is immersed in a toluene solution of 5mM allyltrichlorosilane to react for 24 hours After taking it out, wash it thoroughly with toluene, acetone and distilled water and dry it;

[0040] (2) Construction of multi-functional chemical surface: firstly, drop the ethanol mixed solution of compound 1 (80mM, 1ml) and DMPA (40mM, 1ml) onto the surface of the stamp, absorb it for 3 minutes, then dry it slowly with Ar gas, and combine with the double bond The surface of the modified material is fully contacted, and the stamp is removed after 365nm ultraviolet light irradiation for 3 minutes, ultrasonically cleaned with ethanol solution and dried with Ar, and the substrate is further immersed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com