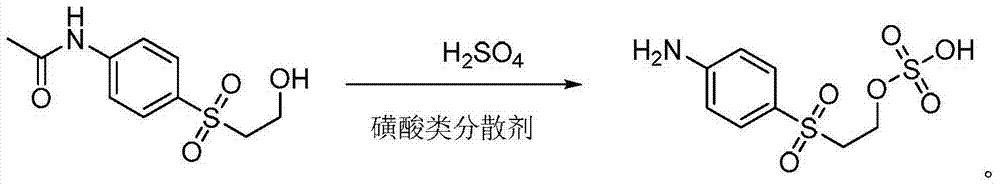

Synthesis method of para-beta-hydroxyethylsulfonyl sulfate aniline

A technology of hydroxyethyl sulfone sulfuric acid and hydroxyethyl sulfone acetanilide, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of high viscosity of the reaction system, unfavorable later use, large equipment loss and the like , to achieve the effect of reducing reaction energy consumption, reducing equipment loss and improving equipment profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 850kg of p-β-hydroxyethyl sulfone acetanilide into the mixing pot, then add 2kg of dispersant NNO, mix for 1 hour, add the mixed material to the p-β-hydroxyethyl sulfide with 355kg of sulfuric acid In the synthesis pot of sulfone sulfate aniline, the temperature is raised to 120°C for esterification reaction. After 6 hours of reaction, the semi-finished product of p-β-hydroxyethylsulfone sulfate aniline is obtained; after the semi-finished product of p-β-hydroxyethylsulfone sulfate aniline is crushed Obtain 994kg of p-beta-hydroxyethyl sulfone sulfate aniline and 210kg of 94% acetic acid. Its HPLC purity is 97.23%, the retention time is consistent with commercially available standard products, the ammonia value is 97.5%, and the ester value is 95.5%, which meets the quality requirements of p-β-hydroxyethyl sulfone sulfate aniline. At the same time, the reaction current load is 12A, The hardness is 1.5, and the insoluble matter is 0.05%.

Embodiment 2

[0025] Add 850kg of p-hydroxyethyl sulfone acetanilide into the blending pot, then add 1.5kg of 1:1 dispersant NNO and dispersant MF mixing aids, mix for 1 hour, then add the mixture to In the p-beta-hydroxyethyl sulfone sulfate aniline synthetic pot of the sulfuric acid of band 355kg, 110 ℃ of temperature rises carry out esterification reaction, after reaction 8 hours, get p-beta-hydroxyethyl sulfone sulfate aniline semi-finished product; -Hydroxyethyl sulfone sulfate aniline semi-finished product obtains 215kg of p-beta-hydroxyethyl sulfone sulfate aniline 992.5kg and 93% acetic acid after pulverizing. Its HPLC is 97.8%, the retention time is consistent with the commercially available standard product, the ammonia value is 97.5%, and the ester value is 95.3%, which meets the quality requirements of p-β-hydroxyethyl sulfone sulfate aniline. At the same time, the reaction current load is 10A, the hardness 1.2, insolubles 0.04%.

Embodiment 3

[0027] Add 850kg of p-β-hydroxyethyl sulfone acetanilide into the mixing pot, then add 2kg of dispersant APEO, mix for 1 hour, add the mixture to the p-β-hydroxyethyl sulfide with 355kg of sulfuric acid In the synthesis pot of sulfone sulfate aniline, the temperature is raised to 110°C for esterification reaction. After 8 hours of reaction, the semi-finished product of p-β-hydroxyethylsulfone sulfate aniline is obtained; after the semi-finished product of p-β-hydroxyethylsulfone sulfate aniline is crushed Obtain 993kg of p-beta-hydroxyethyl sulfone sulfate aniline and 210kg of 93.7% acetic acid. Its HPLC is 96.6%, the retention time is consistent with the commercially available standard product, the ammonia value is 96.5%, and the ester value is 94.8%, which meets the quality requirements of p-β-hydroxyethyl sulfone sulfate aniline. At the same time, the reaction current load is 18A, the hardness 3. Insoluble matter is 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com