Method and system for preparing high-whiteness and high-purity aluminum hydroxide from high-silicon bauxite

A high-silica bauxite and aluminum hydroxide technology, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problems of high energy consumption, harsh requirements, and high safety risks in the production process, and achieves The effect of lower sintering temperature, high homogenization efficiency, and low-cost extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

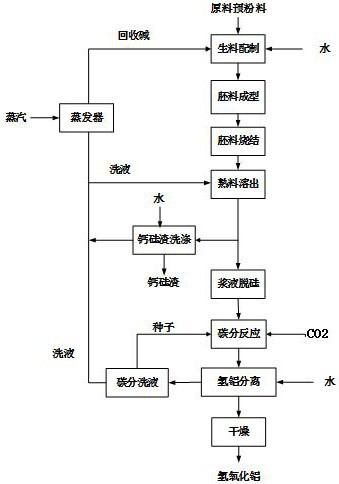

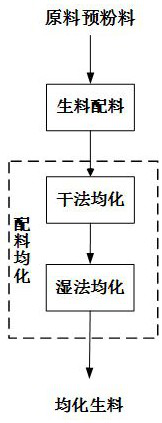

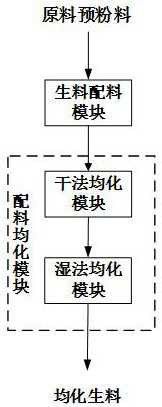

[0177] figure 1 It is a schematic diagram of the process flow for preparing high-white and high-purity aluminum hydroxide of the present invention; figure 2 It is a schematic flow chart of the raw material treatment process for preparing high-white and high-purity aluminum hydroxide of the present invention, image 3 It is a schematic structural diagram of a raw material processing system for preparing high-white and high-purity aluminum hydroxide of the present invention, Figure 6 It is a schematic structural diagram of the system for preparing high-white and high-purity aluminum hydroxide of the present invention.

[0178] Raw material treatment of high white and high purity aluminum hydroxide

[0179] use as figure 2 and image 3 The process and flow process are used to process the raw materials for the preparation of high-white and high-purity aluminum hydroxide to prepare the homogenized raw meal for the reaction.

[0180] First, take high-silicon bauxite, coal ga...

Embodiment 2

[0201] Carry out batching, sintering, prepare aluminum hydroxide with reference to embodiment 1, and embodiment 1 is different:

[0202] Homogenized raw material preparation: high-silicon bauxite, coal gangue, coal powder, carbide slag, and soda ash are respectively fed into the pre-powder with a fineness of about 200 mesh in the Raymond mill, and the ingredients are prepared according to the same formula as in Example 1 Complete the preparation of homogenized raw meal.

[0203] Blank forming: using Figure 4 Medium G type prepares self-heating sintered embryo body, round cake shape body, diameter 10cm, thickness 3cm, cross-sectional area 200cm 2 , Use the demoulding tool to export the G-shaped blank, and finally dry the blank.

[0204] Blank material sintering: put the blank material into the roasting furnace, stack and sinter the blank material according to the height direction of the blank material to prepare clinker.

[0205] In this example, the G-type self-heating bil...

Embodiment 3

[0208] Carry out batching, homogenization, molding with reference to embodiment 1, and embodiment 1 difference is:

[0209] Homogenized raw material preparation: high-silicon bauxite, coal gangue, coal powder, carbide slag, and soda ash are respectively fed into the pre-powder with a fineness of about 160 mesh in the Raymond mill, and the ingredients are prepared according to the same formula as in Example 1 Complete the preparation of homogenized raw meal.

[0210] Blank forming: using Figure 4 Types B, C, D, E, F and H prepare the self-heating sintered blank, use the demoulding tool to export the blank, and finally dry the blank.

[0211] In this example, the above-mentioned 6 kinds of self-heating blanks were sintered and formed into blanks, and were placed in a roasting furnace for drying, sintering, and cooling under programmed temperature rise. The recovery rate of Al in high-silicon bauxite and coal gangue solid waste was 75- 80%. Prepared high-white and high-purity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com