Method and system for boron removal in industrial silicon refining

A technology of industrial silicon and silicon powder, applied in the field of metallurgy, can solve problems such as difficult separation, long refining and heat preservation time, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

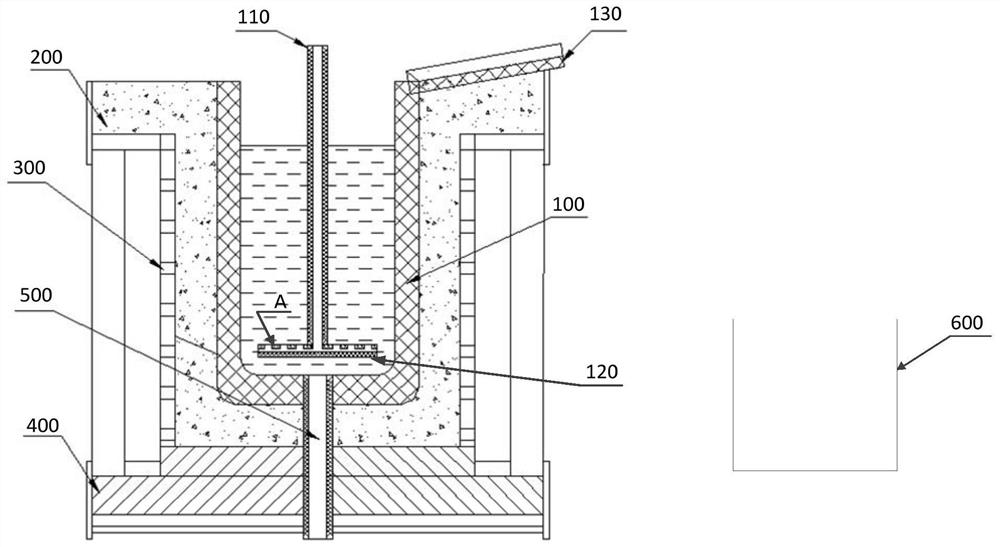

Image

Examples

Embodiment 1

[0049] In this example, boron is removed from industrial silicon powder as follows:

[0050] 1) will be Ca(OH) by mass ratio 2 :Na 2 CO 3 :SiO 2 = 2kg of slag-forming agent prepared at 70:10:20 was added to the graphite crucible of the intermediate frequency induction furnace, and the power of the intermediate-frequency induction furnace was gradually increased to rapidly heat up the slag-forming agent until it was completely melted to obtain a slag-forming agent melt;

[0051] 2) 1kg industrial silicon powder with a B content of 100 meshes and a B content of 10ppmw and an argon gas mixture with a flow rate of 2L / min are sent into the manufacturing process through the through hole on the bottom disk of the graphite hollow device (the height from the bottom of the graphite crucible is 10mm). Bottom of slag melt;

[0052] 3) After the industrial silicon powder is added and completely melted, the measured melt temperature is 1900°C, and the slag-forming agent melt is discharg...

Embodiment 2

[0083] 1) will be Ca(OH) by mass ratio 2 :Na 2 CO 3 :SiO 2 = 2kg of slag-forming agent prepared at 70:10:20 was added to the graphite crucible of the intermediate frequency induction furnace, and the power of the intermediate-frequency induction furnace was gradually increased to rapidly heat up the slag-forming agent until it was completely melted to obtain a slag-forming agent melt;

[0084] 2) 100 orders, B content are that the 2kg industrial silicon powder of 10ppmw and the argon gas mixture with flow rate of 2L / min are sent into the bottom of the slag-forming agent melt through the through hole on the bottom disk of the graphite hollow device;

[0085] 3) After the industrial silicon powder is added and completely melted, the measured melt temperature is 1800°C, and the slag-forming agent melt is discharged through the discharging method at the bottom of the graphite crucible;

[0086] 4) pour the furnace body to pour the silicon melt into the pure water tank with a te...

Embodiment 3

[0089] 1) will be Ca(OH) by mass ratio 2 :Na 2 CO 3 :SiO 2 = 2kg of slag-forming agent prepared at 70:10:20 was added to the graphite crucible of the intermediate frequency induction furnace, and the power of the intermediate-frequency induction furnace was gradually increased to rapidly heat up the slag-forming agent until it was completely melted to obtain a slag-forming agent melt;

[0090] 2) 100 orders, B content are that the 1kg industrial silicon powder of 15ppmw and the argon gas mixture with flow rate of 2L / min are sent into the bottom of the slag-forming agent melt through the through hole on the bottom disk of the graphite hollow device;

[0091] 3) After the industrial silicon powder is added and completely melted, the measured melt temperature is 1900°C, and the slag-forming agent melt is discharged through the discharging method at the bottom of the graphite crucible;

[0092] 4) pour the furnace body to pour silicon melt into the pure water tank with temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com