Method for removing heavy hydrocarbon in natural gas through low-temperature capillary condensation

A technology of capillary condensation and natural gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of freezing of cold boxes, impossible to achieve removal concentration, etc., and achieve the effect of continuous operation, easy operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

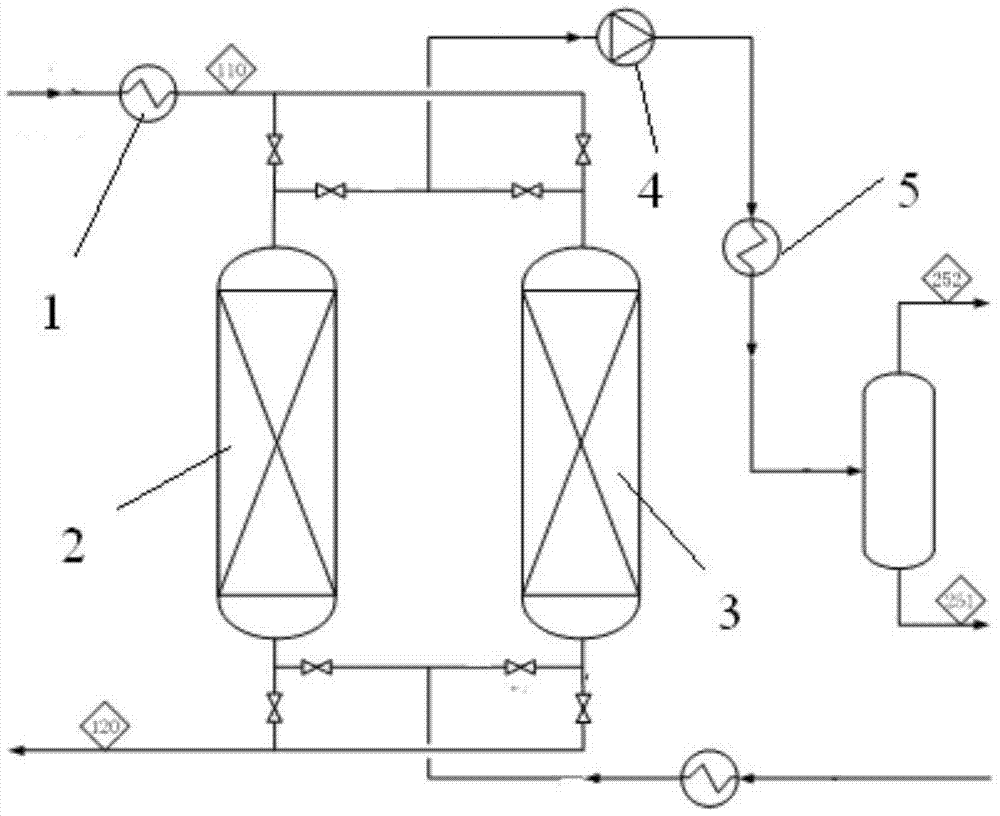

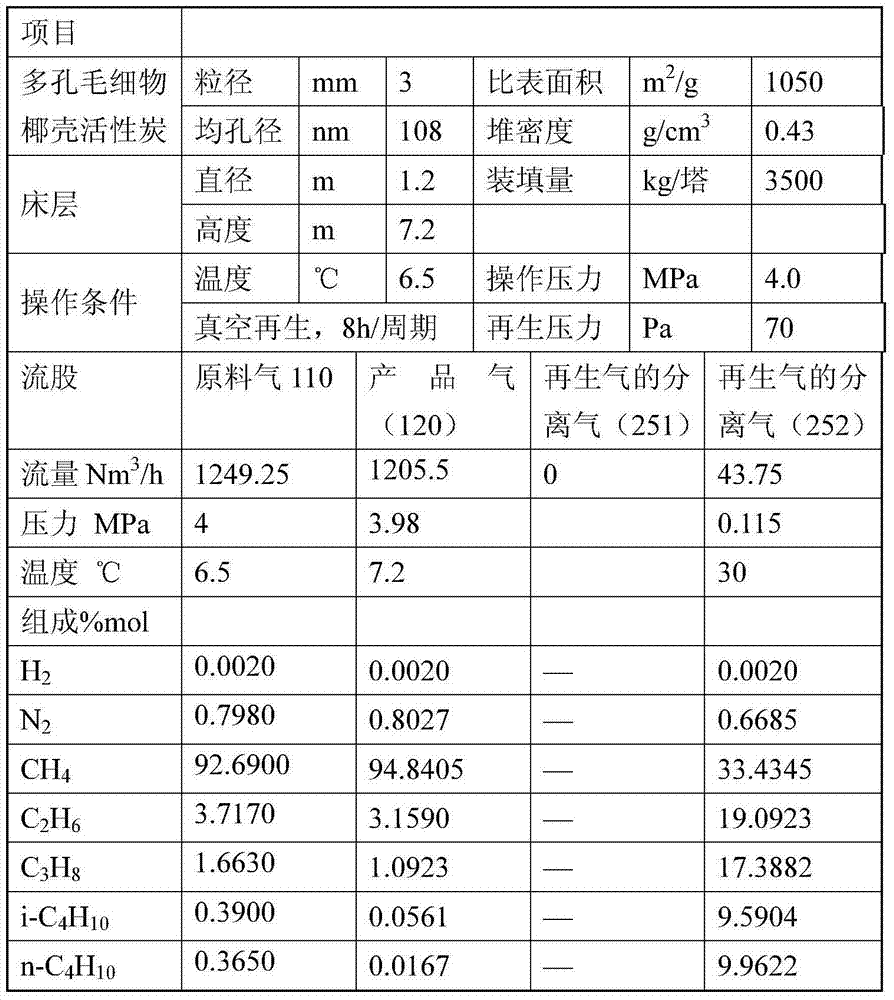

[0032] Such as figure 1 As shown, this process adopts a two-tower low-temperature capillary condensation process for removing heavy hydrocarbons. The structure of the tower of the present invention is the same as that of the adsorption towers currently on the market. The first column 2 and the second column 3 are arranged in parallel and operated out of phase. The capillary porous material filled in the first tower 2 and the second tower 3 is coconut shell activated carbon, the apparent diameter is 3mm, the pore diameter is 7.8nm-15000nm, the concentration is distributed at 108nm, and the specific surface area is 1030m 2 / g, bulk density 0.43g / cm 3 , fully dry before use.

[0033] The raw natural gas is pre-cooled through the first heat exchanger 1, and the pre-cooling temperature is 6.5°C. The pre-cooled low-temperature feed gas enters the first tower 2 from the upper part of the first tower 2, heavy hydrocarbons (hydrocarbons with more than 5 carbon atoms) are enriched a...

Embodiment 2

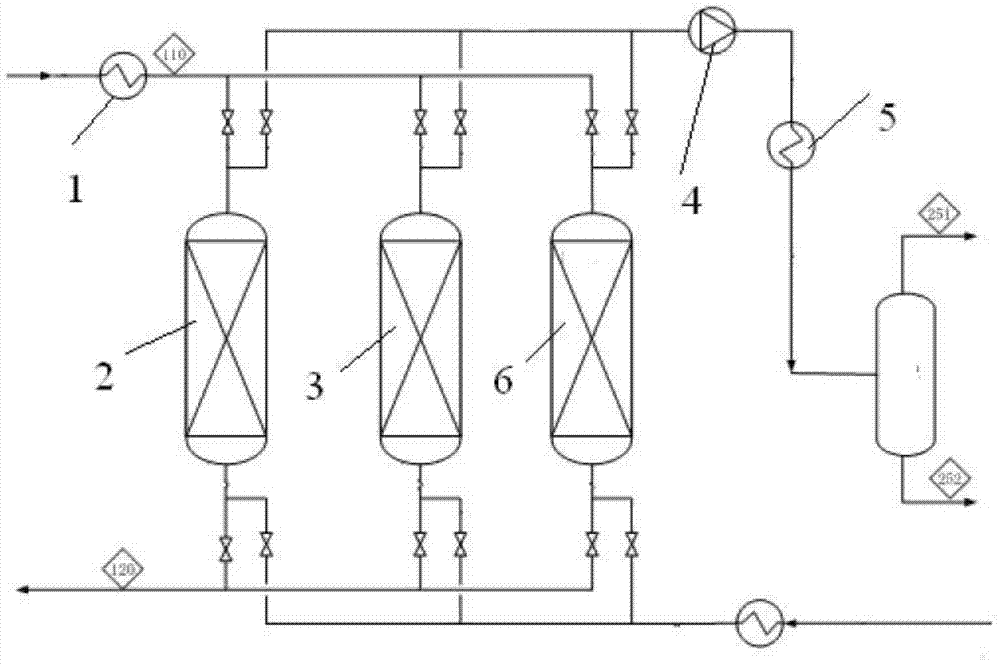

[0041] as attached figure 2 As shown, this process adopts a three-tower low-temperature capillary condensation process. The first, second and third towers 2, 3 and 6 are arranged in parallel and operated in different phases. The capillary porous materials filled in the first, second and third towers 2, 3, and 6 are all silica gel, which is columnar particles with a diameter of 2.5mm, a pore diameter of 8.5-38nm, concentrated distribution at 22nm, and a specific surface area of 350m 2 / g, bulk density 0.75g / cm 3 , fully dry before use.

[0042] The raw natural gas is pre-cooled through the first heat exchanger 1, and the pre-cooling temperature is 5.5°C. Pre-cooled low-temperature capillary condensation of low-temperature raw gas to remove heavy hydrocarbons. Initially, the first tower 2 is in the state of cooling after regeneration, while the second tower is already in the middle of the low-temperature capillary condensation process, and the third tower 6 is in the low-t...

Embodiment 3

[0049] Such as figure 1 As shown, this process adopts a two-tower low-temperature capillary condensation process for removing heavy hydrocarbons. The first column 2 and the second column 3 are arranged in parallel and operated out of phase. The capillary porous material filled in the first tower 2 and the second tower 3 adopts mesoporous molecular sieve MCM-41, with an apparent diameter of 3mm, a pore diameter of 15nm, and a specific surface area of 985m 2 / g, bulk density 0.68g / cm 3 , fully dry before use.

[0050] The raw natural gas is pre-cooled through the first heat exchanger 1, and the pre-cooling temperature is 5.8°C. The pre-cooled low-temperature feed gas enters the first tower 2 from the upper part of the first tower 2, heavy hydrocarbons (hydrocarbons with more than 5 carbon atoms) are enriched and condensed in the bed layer, and the purified product gas flows from the first tower 2 The lower part flows out. The operating pressure of the first column 2 is 2M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com