Detection method and detection device for flowing conditions of pulverized coal conveyed in high pressure dense phase pneumatic mode

A technology of pneumatic conveying and flow state, which is applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve problems affecting the accuracy of judgment results, limited scope of application, and influence of interval ranges, and achieves simple structure, low price, and high detection results. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below with reference to accompanying drawing, specific embodiment of the present invention is described in more detail:

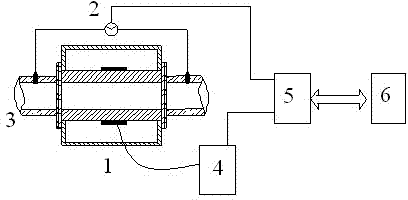

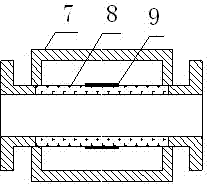

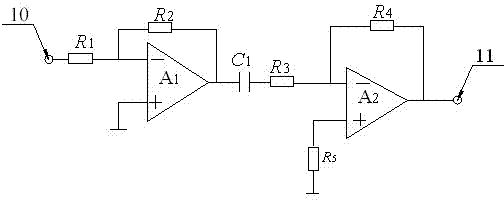

[0032] 1. As attached figure 1 As shown, the electrostatic sensor 1 and the probe 2 of the differential pressure sensor are respectively installed on the high-voltage dense-phase pneumatic conveying horizontal pipeline 3, the signal output wire of the electrostatic sensor probe needs to be connected to the input end of the pre-voltage amplifier circuit 4, and the amplifier circuit The output end is connected with the input end of the high-speed data acquisition card 5, and the acquisition card is controlled by a computer 6. The output end of the differential pressure sensor is directly connected to the input end of the acquisition card. When the pulverized coal flows in the pipeline, the signal generated by the electrostatic sensor probe is amplified by the amplifier circuit and then transmitted to the computer by the acquisition card, while the dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com