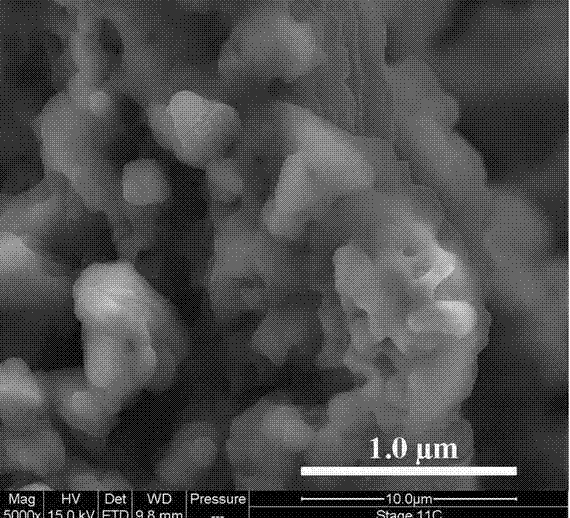

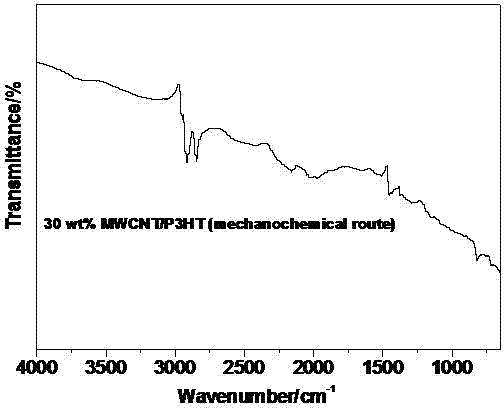

Method for preparing carbon nano tube/poly (3-hexyl) thiophene composite thermoelectric materials

A technology of thermoelectric materials and zirconia, which is applied in the field of preparation of CNT/P3HT composite thermoelectric materials, can solve the problems of easy pollution of the environment and a large amount of organic solvents, and achieve the effect of simple process and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Ingredients: First, 48.55g zirconia grinding balls with a diameter of 2mm and 7.71g FeCl 3 Add it into a zirconia ball milling jar with a volume of 100 mL, and after mixing evenly, add 2 g of 3-HT monomer dropwise, seal the ball milling jar and put it into a ball mill for ball milling.

[0038] (2) Ball milling; the technical parameters of ball milling are: 100 rpm for 30 minutes of rotation speed, and then 500 rpm for 10 minutes of rotation speed.

[0039] (3) Centrifugation and washing; after the ball milling, transfer the balls and reactants in the ball milling jar to a beaker, add deionized water and stir, take out the zirconia grinding balls from the beaker with tweezers, and then apply the tweezers to the beaker. The black product was washed with deionized water, centrifuged, and the washing and centrifugation steps were repeated until the upper solution in the centrifuge tube was colorless,

[0040] (4) Drying. Put the centrifuge tube together with the prod...

Embodiment 2

[0043] (1) Ingredients: First, 76g zirconia grinding balls with a diameter of 2mm and 8.10g FeCl 3 Put it into a zirconia ball milling jar with a volume of 200 mL, then add 0.6 g of MWCNT, after mixing evenly, add 1.4 g of 3-HT monomer dropwise, seal the ball milling jar and put it into a ball mill for ball milling.

[0044] (2) Ball milling; the technical parameters of ball milling are: the speed of 300rpm, the time of 60min, then the speed of 1000rpm, and the time of 10min.

[0045] (3) Centrifugation and washing; after the ball milling, transfer the balls and reactants in the ball milling tank to the beaker, add deionized water and stir, take out the zirconia grinding balls from the beaker with tweezers, and then apply the tweezers to the beaker. The black product was washed with deionized water, centrifuged, and the washing and centrifugation steps were repeated until the upper solution in the centrifuge tube was colorless,

[0046] (4) Drying. Put the centrifuge tube an...

Embodiment 3

[0050] (1) Ingredients: First, 87.1g of zirconia grinding balls with a diameter of 2mm and 7.71g of FeCl were mixed 3 Add it into a zirconia ball milling jar with a volume of 200 mL, then add 1.0 g MWCNT, after mixing evenly, add 1.0 g 3-HT monomer dropwise, seal the ball milling jar and put it into a ball mill for ball milling.

[0051] (2) Ball milling; the technical parameters of the ball milling are: rotation speed 300rpm, time 30min, then rotation speed 500rpm, time 30min.

[0052] (3) Centrifugation and washing; after the ball milling, transfer the balls and reactants in the ball milling jar to a beaker, add deionized water and stir, take out the zirconia grinding balls from the beaker with tweezers, and then apply the tweezers to the beaker. The black product was washed with deionized water, centrifuged, and the washing and centrifugation steps were repeated until the upper solution in the centrifuge tube was colorless,

[0053] (4) Drying. Put the centrifuge tube and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com