Method for increasing yield of anidulafungin precursor compound Echinocandin B

A precursor compound, the technology of Anifungin, applied in the field of increasing the yield of Echinocandin B, the precursor compound of Anifungin, can solve the problems of low level of fermentation preparation and achieve the effect of improving the level of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

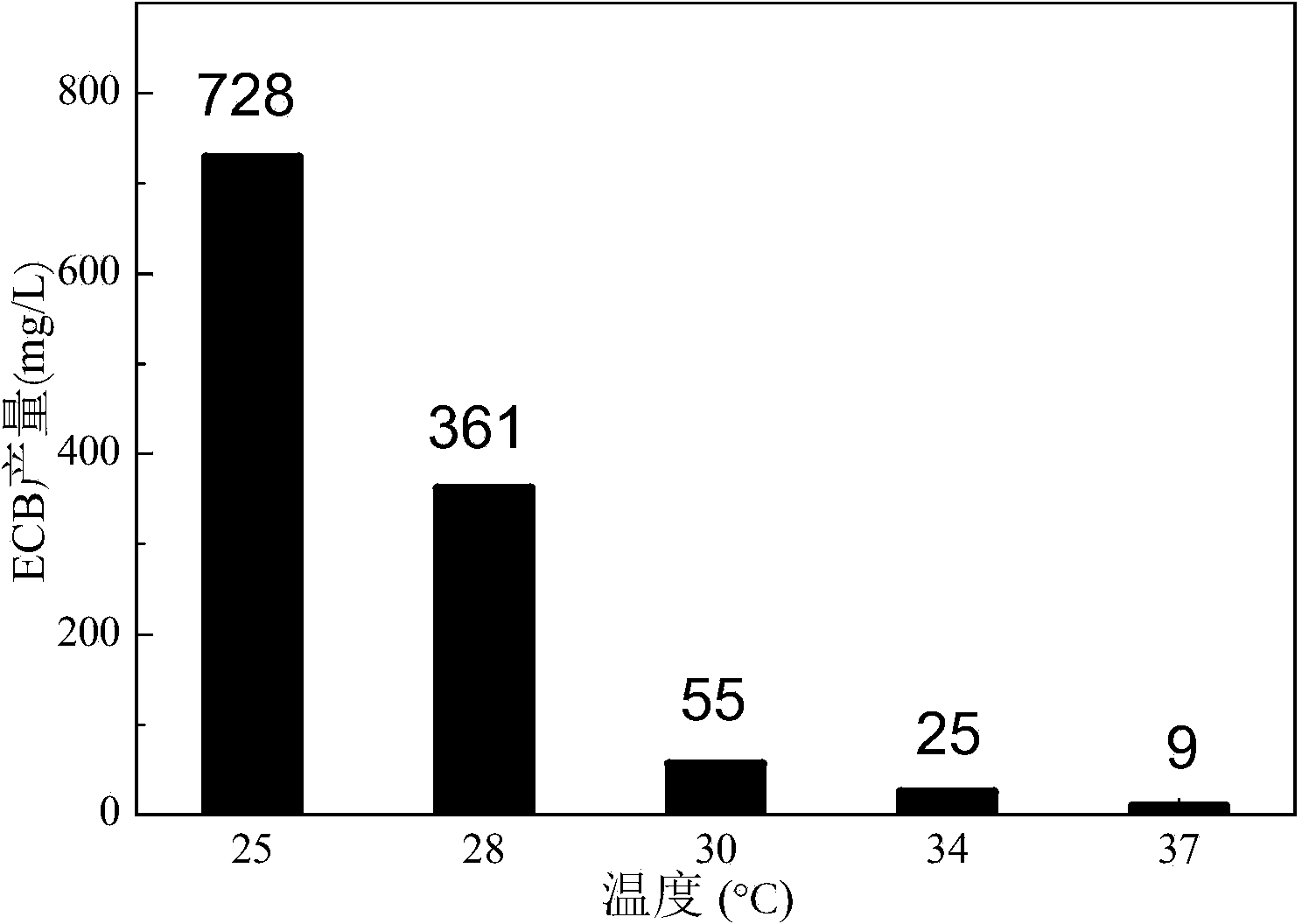

[0025] The strain used in the examples of the present invention is Aspergillus nidulans ZJB09223 (CCTCC NO: M2012300). This strain was deposited in the China Type Culture Collection on July 25, 2012, and has been filed separately as a new strain.

[0026] (1) Aspergillus nidulans ZJB09223 seed culture:

[0027] Take a ring of dark green colonies from the PDA slant culture medium and connect it to the seed culture medium. The culture temperature is 25°C, the shaker speed is 220r / min, and the culture is 2 days to obtain the seed liquid; the seed culture medium has the following composition :Glucose 10g / L, glycerol 10g / L, cottonseed powder 25g / L, solvent is water, pH6.8~7.0, sterilized at 115℃ for 30min;

[0028] (2) Aspergillus nidulans ZJB09223 fermentation culture:

[0029] The composition of the fermentation medium is as follows: peanut oil 20g / L, glycerol 10g / L, peptone 10g / L, L-proline 2g / L, mannitol 90g / L, soybean meal 40g / L, K 2 HPO 4 ·3H 2 O8g / L, MgSO 4 ·7H 2 O0.5g / L, MnSO 4 ·H ...

Embodiment 2

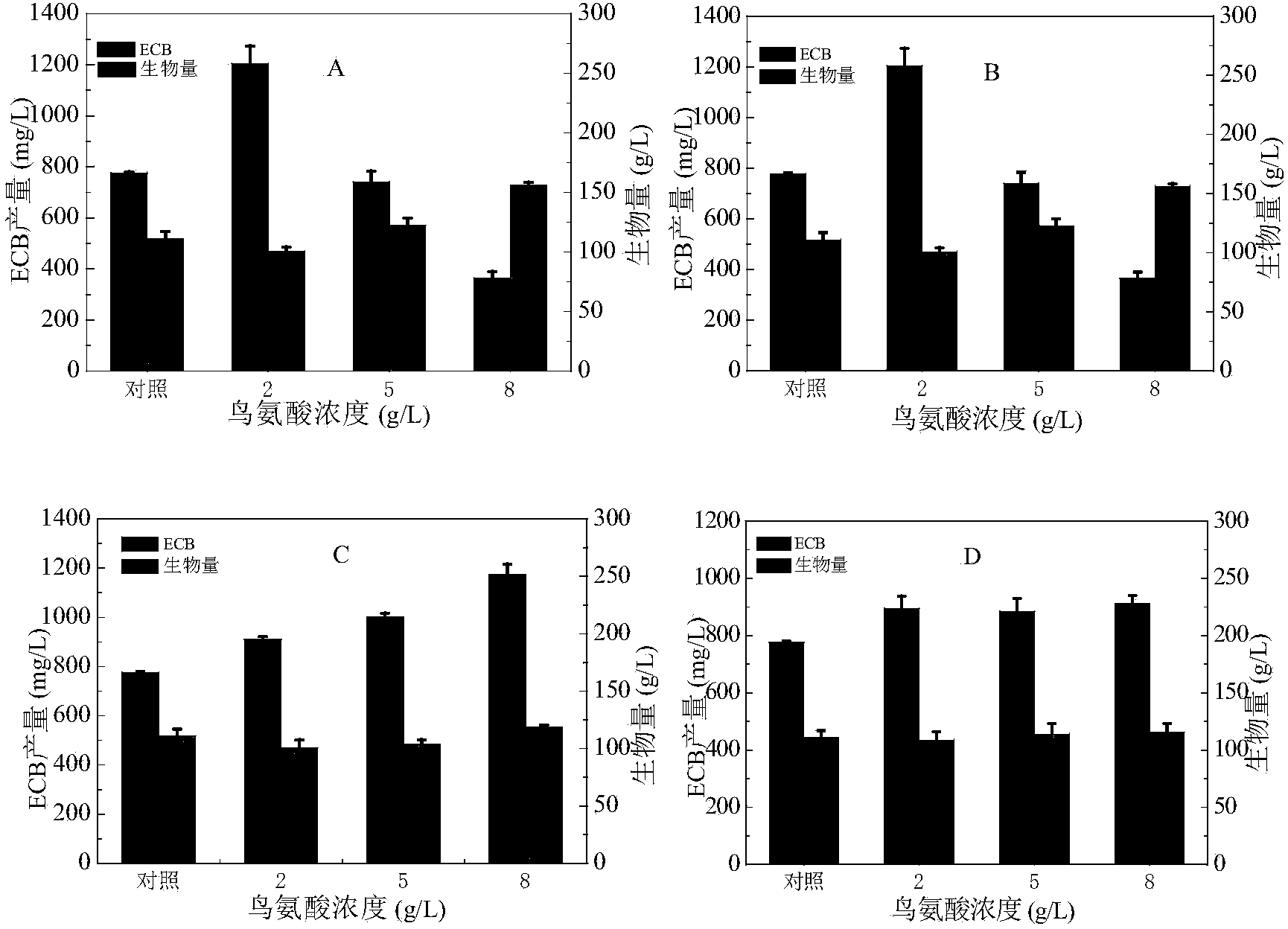

[0032] According to the results of Example 1, we chose to change the temperature during the culture process. The experiment started with the fermentation culture at 25°C, 28°C, and 37°C, and then adjusted the temperature after 3 days, 6 days, and 9 days. The adjustment method is: adjust 28°C and 37°C to 25°C and cultivate until the end of fermentation; adjust 25°C to 28°C to cultivate until the end of fermentation, and determine the ECB content. The results are shown in Table 1. High temperature (28~37°C) cultivation and subsequent low temperature (25°C) cultivation can greatly increase ECB production. Using 37°C for the first 3 days and 25°C for the next 9 days can increase the ECB fermentation level to 1237mg / L, which is 69.9% higher than the constant temperature culture at 25℃.

[0033] Table 1: The influence of different temperature adjustment methods and adjustment time on ECB output

[0034]

Embodiment 3

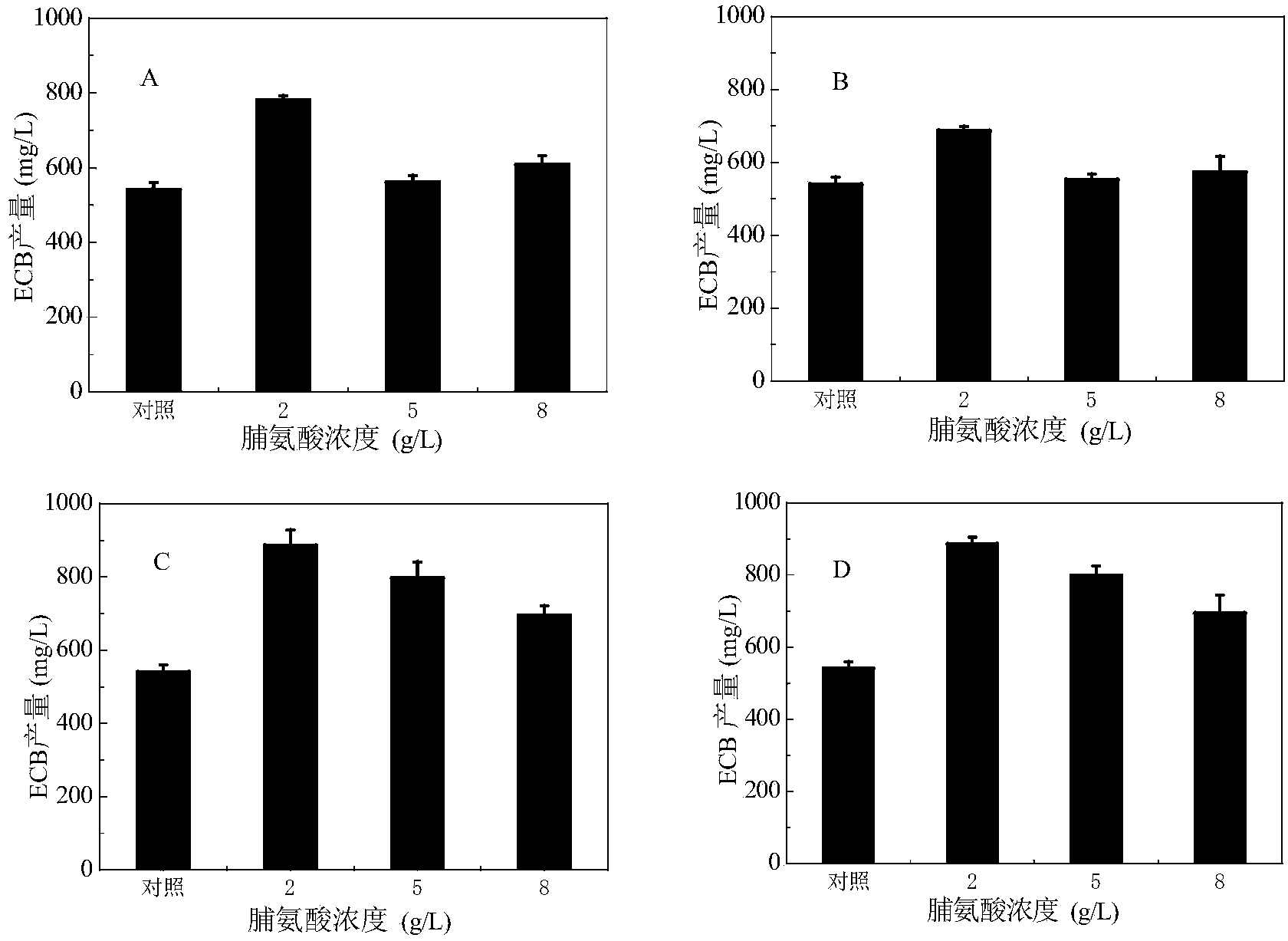

[0036] It is reported in related literature that proline plays an important role in the growth and metabolism of fungal microorganisms. The experiment examined the effects of different addition times and different concentrations of proline on the fermentation results.

[0037] The composition of the original fermentation medium of ECB in the experiment is: peanut oil 20g / L, glycerol 10g / L, peptone 10g / L, L-proline 5g / L, mannitol 90g / L, soybean meal 40g / L, K 2 HPO 4 ·3H 2 O8g / L, MgSO 4 ·7H 2 O0.5g / L, MnSO 4 ·H 2 O0.1g / L, FeSO 4 ·7H 2 O0.05g / L, CaCl 2 0.3g / L, solvent is water, pH7.0. The seeds cultured for 2 days were put into the fermentation medium at a 10% inoculum amount, and the culture time was 12 days under the conditions of 25°C and a shaker rotation speed of 220r / min.

[0038] Taking the above fermentation medium as a control, proline was added to the fermentation broth at different times to make the final concentrations of 2g / L, 5g / L, and 8g / L, respectively, to investigate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com