Oil supplying system of oil pump

An oil supply system and oil pump technology, applied in the direction of pressure lubrication of lubricating pumps, lubrication of valve accessories, engine components, etc., can solve the problem of affecting the lubrication effect, insufficient lubricating oil for the inner wall of the upper cylinder of the crankshaft, and insufficient oil supply for the crankcase And other problems, to achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with specific embodiments.

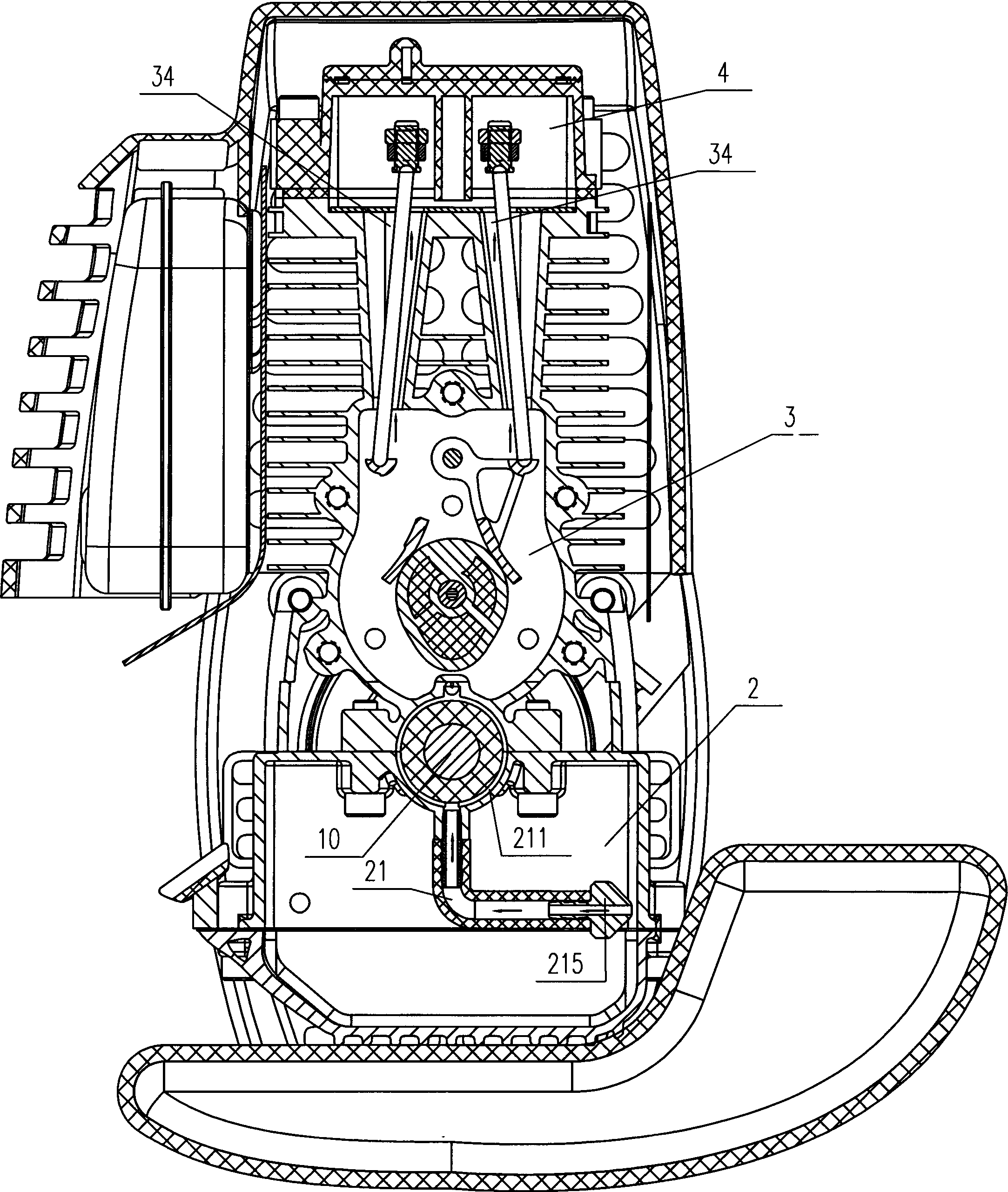

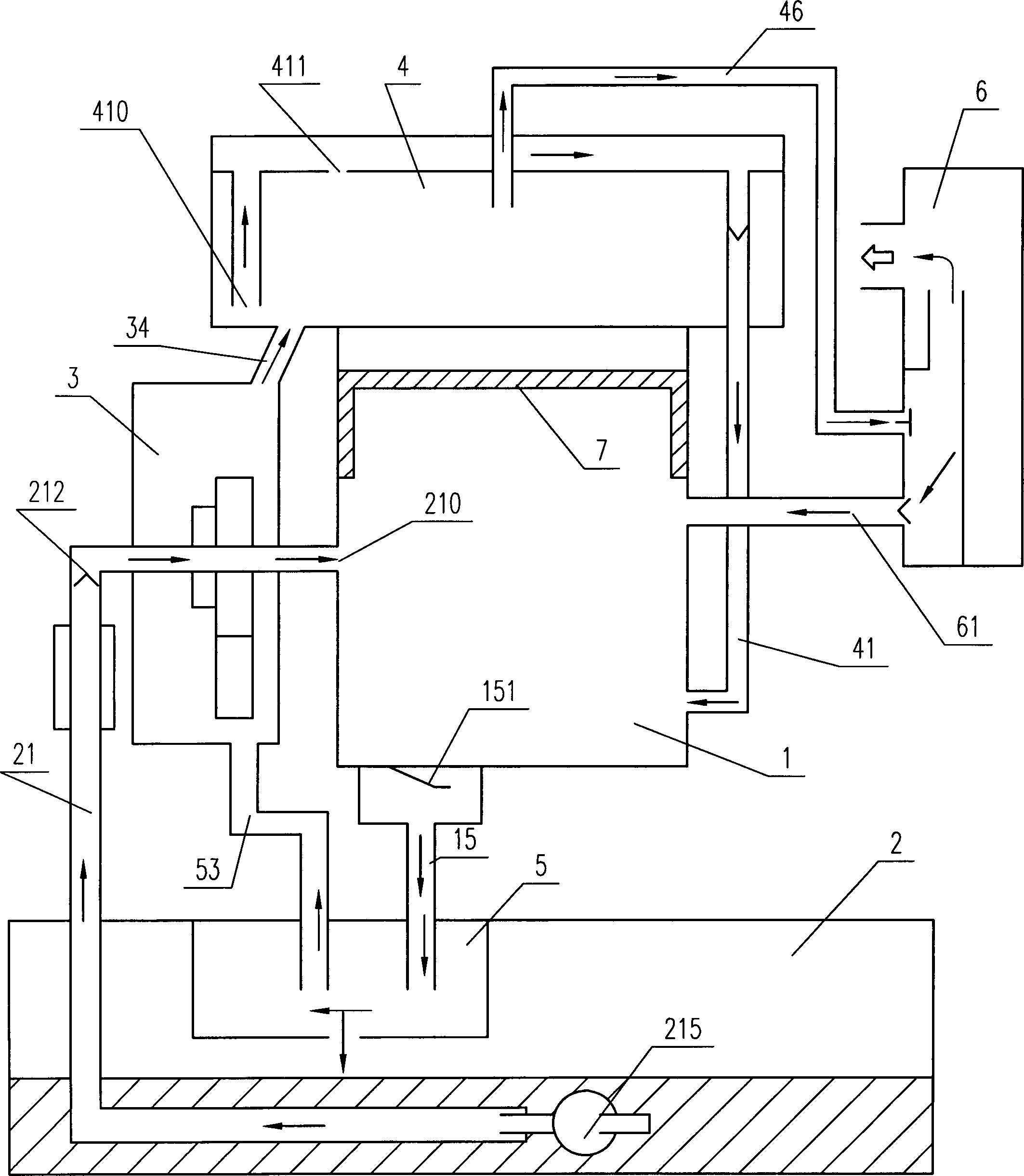

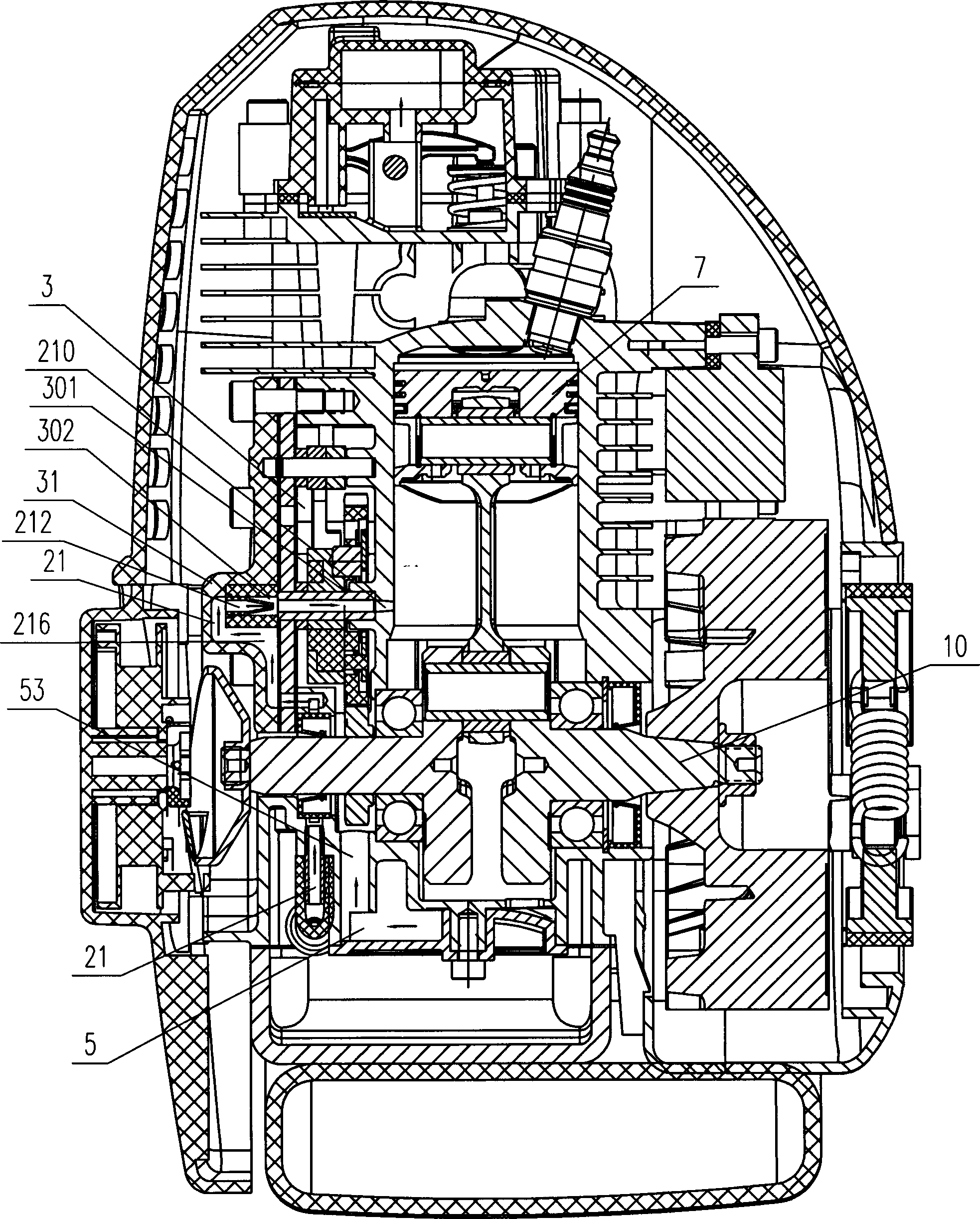

[0028] As shown in the figure, the four-stroke engine of the preferred embodiment of the present invention includes a crankcase 1 , an oil pan 2 , a cam chamber 3 , a rocker chamber 4 and an air filter 6 . The oil pan 2 is used to store lubricating oil. Above the oil pan 2 is the crankcase 1. The crankshaft 10 is arranged in the crankcase 1 and engaged with the piston 7 in the cylinder 8. The oil pan 2 and the crankcase 1 communicate through an oil supply passage 21. . A distributing chamber 5 is provided below the crankcase 1, and the crankcase and the distributing chamber are communicated through the first oil delivery channel 15. The distributing chamber 5 can separate oil and gas, and the separated liquid lubricating oil flows into the oil pan 2 through the small hole at the bottom of the separation chamber. The remaining gaseous lubricating oil passes through, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com