Selective absorption filtering structure

A technology of selective absorption and medium, applied in optics, optical components, instruments, etc., can solve the problems of degradation of absorption efficiency, complex preparation process, sensitivity to the polarization state of incident light, etc., to achieve the effect of easy implementation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

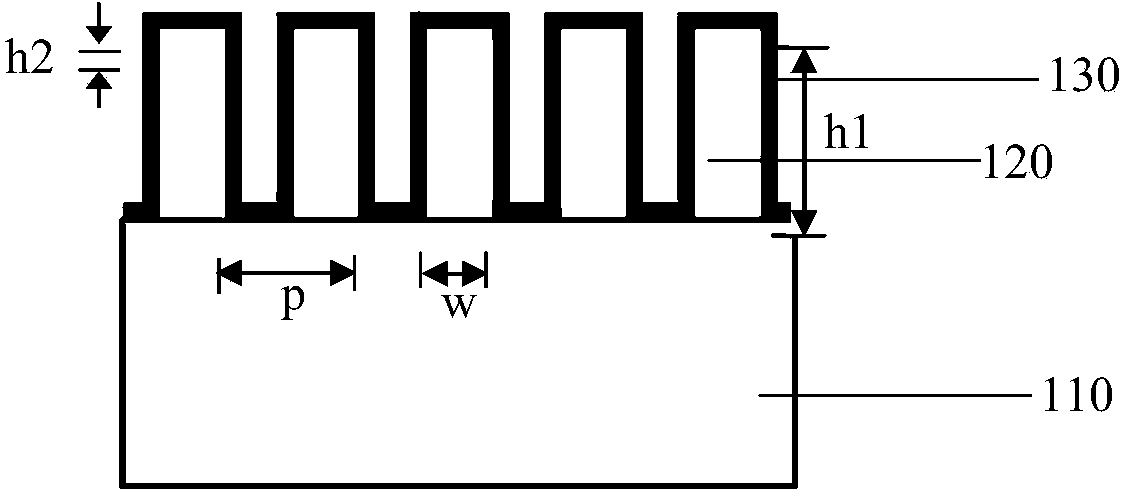

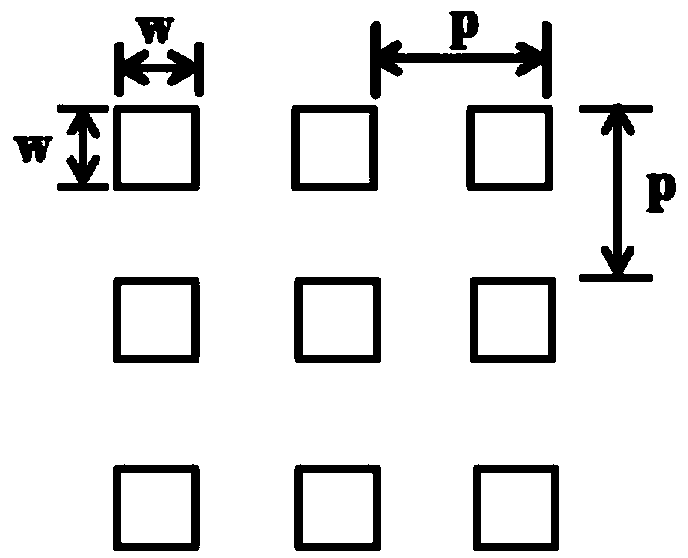

[0037] In this embodiment, nickel is used as the metal layer, and the dielectric constant of nickel is as follows: Figure 11 As shown, wherein the solid line represents the real part in the dielectric constant, and the dotted line represents the imaginary part. It can be seen that the real part and the imaginary part of the dielectric constant of nickel meet the requirements of the present invention in the visible light range, that is, the imaginary part is greater than the real part. The absolute value of the part. see figure 1 , in this embodiment, the substrate 110 is a flexible material, specifically PET or PC. The medium micro-nano unit 120 is a nano-square column arranged in a quadrilateral, as shown in FIG. 2( a ). Metal layer 130 is nickel. Further, the period of the medium micro-nano unit is p=220nm, the duty ratio is F=0.4, and the thickness h1=100nm. Metal layer thickness h2=20nm.

[0038] The absorption characteristics and angle tolerance of selective absorpt...

Embodiment 2

[0043] In this embodiment, the material of the metal layer is changed, the metal layer 130 is chromium, and the dielectric constant of chromium is as follows Figure 12 As shown, wherein the realization represents the real part of the dielectric constant, and the dotted line represents the imaginary part. It can be seen that the real part and the imaginary part of the dielectric constant of chromium meet the requirements of the present invention in the visible light range, that is, the imaginary part is greater than the absolute value of the real part . Please continue to see figure 1 , in this embodiment, the substrate 110 is a flexible material, specifically PET or PC. The medium micro-nano unit 120 is a nano-square column arranged in a quadrilateral, as shown in FIG. 2( a ). Further, the period of the medium micro-nano unit is p=220nm, the duty ratio is F=0.4, and the thickness h1=100nm. Metal layer thickness h2=20nm.

[0044] The absorption characteristics and angle to...

Embodiment 3

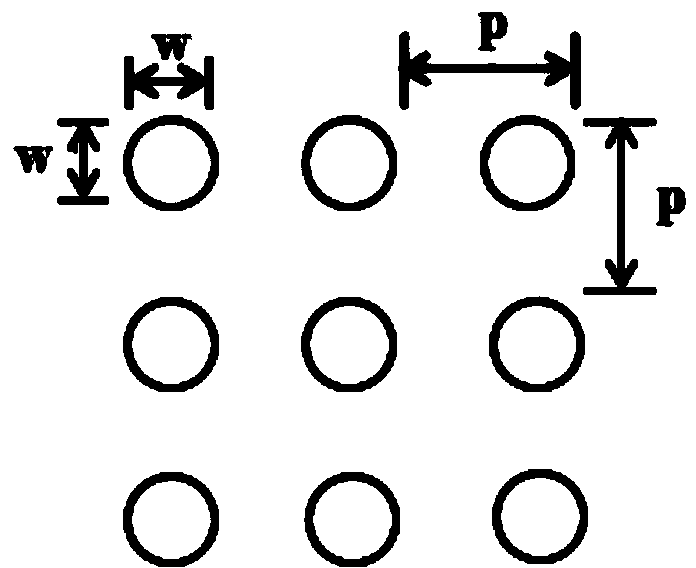

[0049] In this embodiment, by changing the shape of the medium micro-nano unit, the influence of the shape of the medium micro-nano unit on the effect of the selective filter structure of the present invention is studied. As shown in FIG. 2( b ), the substrate 110 is a flexible material, specifically PET or PC. The dielectric micro-nano unit 120 is nano-circular pillars arranged in a quadrangular shape, and the metal layer 130 is chromium. Further, the period of the medium micro-nano unit is p=220nm, the duty ratio is F=0.4, and the thickness h1=100nm. Metal layer thickness h2=20nm.

[0050] The absorption characteristics and angle tolerance of selective absorption filter structures are analyzed by rigorous coupled wave theory (RCWA). TM and TE polarized light is incident from the top of the structure at angles ranging from 0° to 45°.

[0051] Figure 7 The relationship diagram of the absorption spectrum of the TM polarized light of the selective absorption filter structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com