Vacuum interrupter compound contact structure and interrupter suitable for capacitive current breaking

A technology of vacuum interrupter and composite contact, which is applied in the direction of high voltage/high current switch, electric switch, circuit, etc. It can solve the problem of generating a large number of metal particles, affecting the insulation strength of vacuum interrupter, and unable to reduce the impact of closing inrush current on vacuum. Interruption chamber contact surface damage and other problems, to achieve the effect of ensuring insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

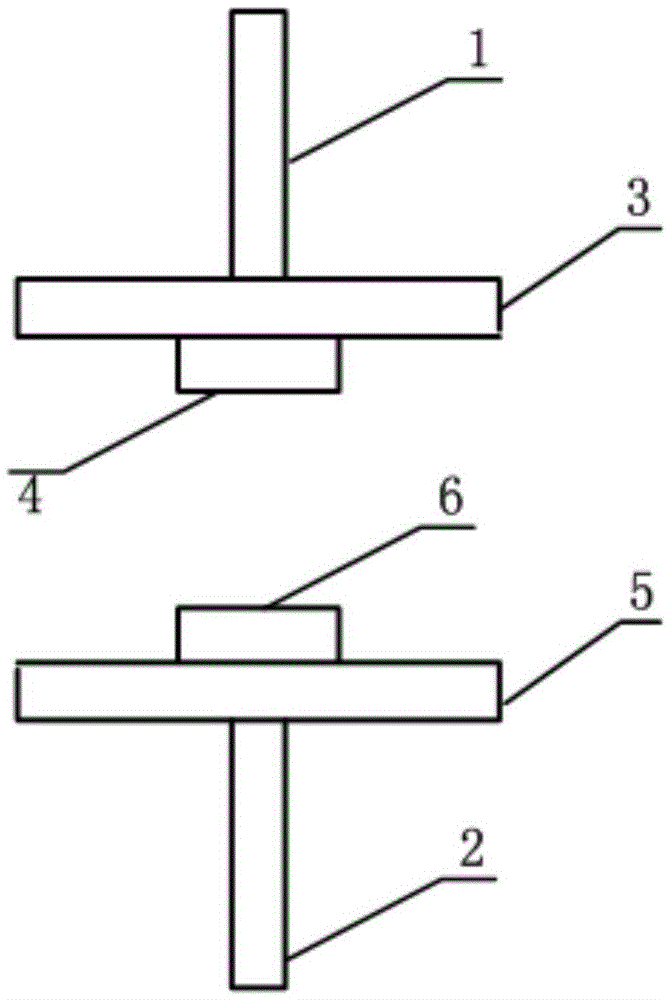

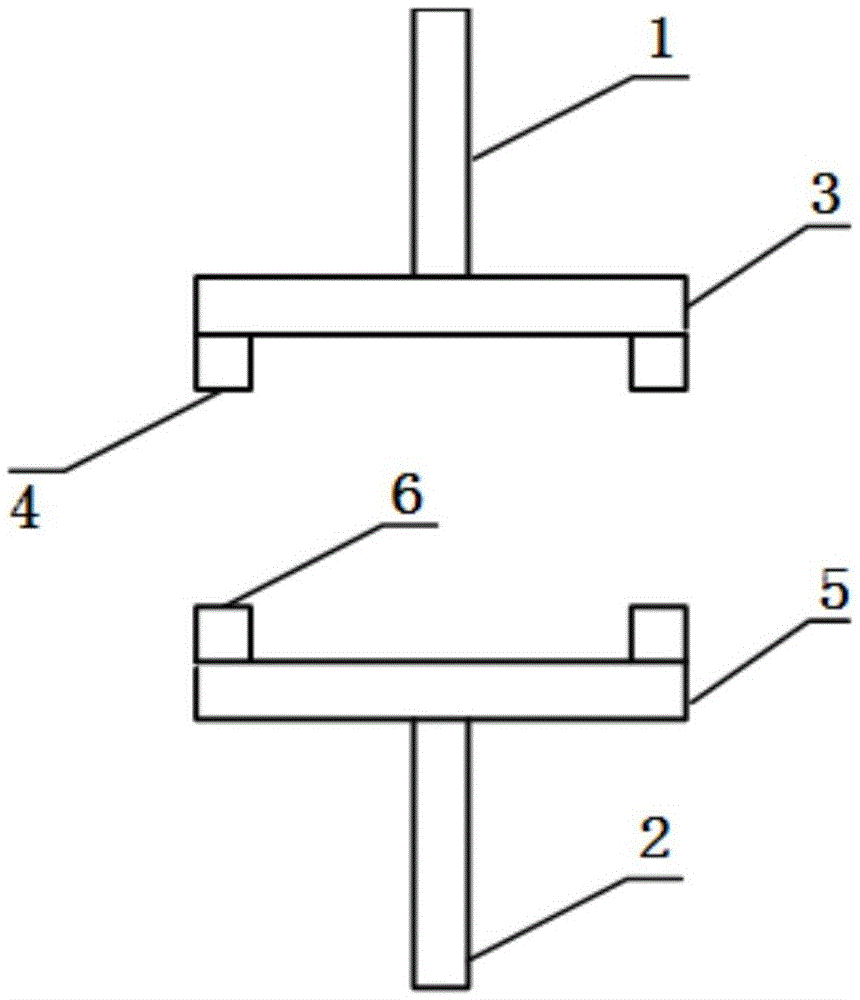

[0018] like figure 1 and figure 2 As shown, the present invention is a composite contact structure of a vacuum interrupter suitable for capacitive current breaking. A pair of dynamic and static conductive rods composed of a dynamic conductive rod 1 and a static conductive rod 2 are respectively fixed on the dynamic conductive rod 1 and the static conductive rod 2. The moving end contact and the static end contact at the top of the proximal end of the static conductive rod 2 are composed of a moving end contact made of the moving end contact material B3 and a moving end of a material different from the moving end contact material B3 fixed above the moving end contact material B3. The contact material A4 is composed of the moving end contact material A4 covering part of the area of the moving end contact material B3; the static end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com