Floated solids separation

A floating body and solid technology, applied in the direction of solid separation, separation method, filtration separation, etc., can solve the problems of increasing transportation cost, difficult and expensive removal of free water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] "Top sludge," "sludge," or "float" is a mixture of separator, air, and water that has been floated to a surface by microbubbles using a DAF system. Isolates can include total suspended solids, which include fats, oils, grease, insoluble impurities, or any other solids suspended in water or wastewater. It is advantageous to separate the solids from free water before further processing.

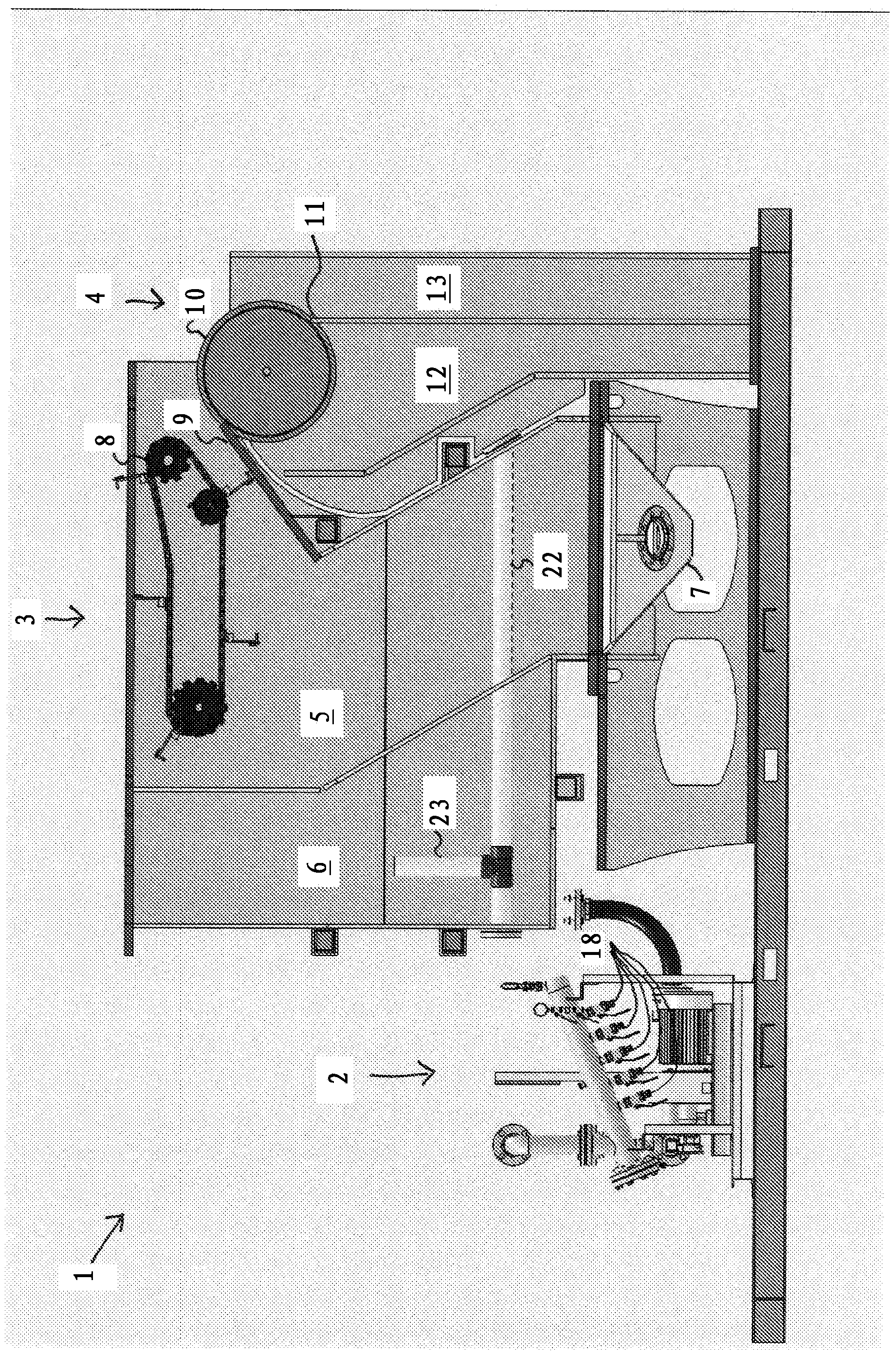

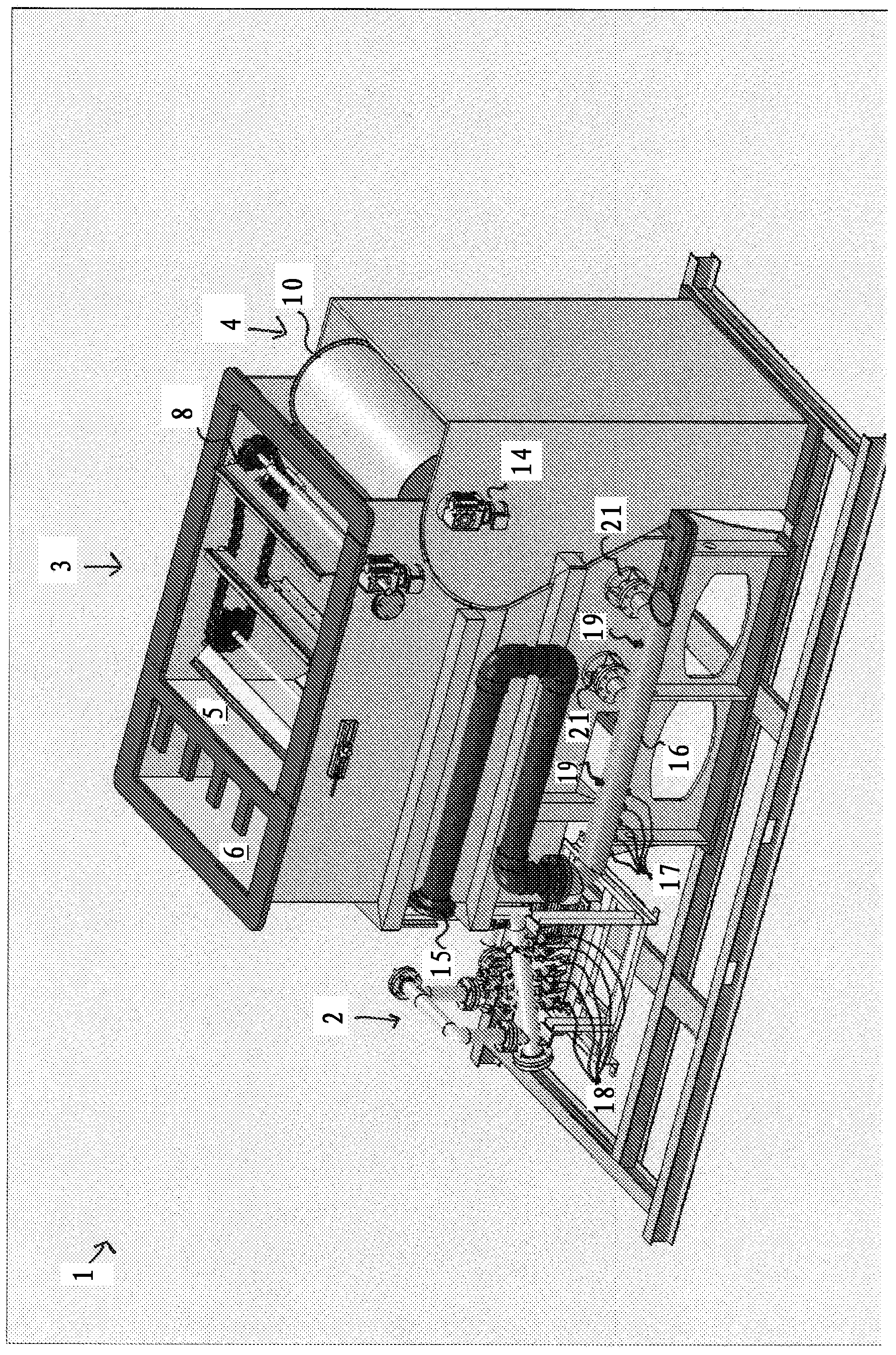

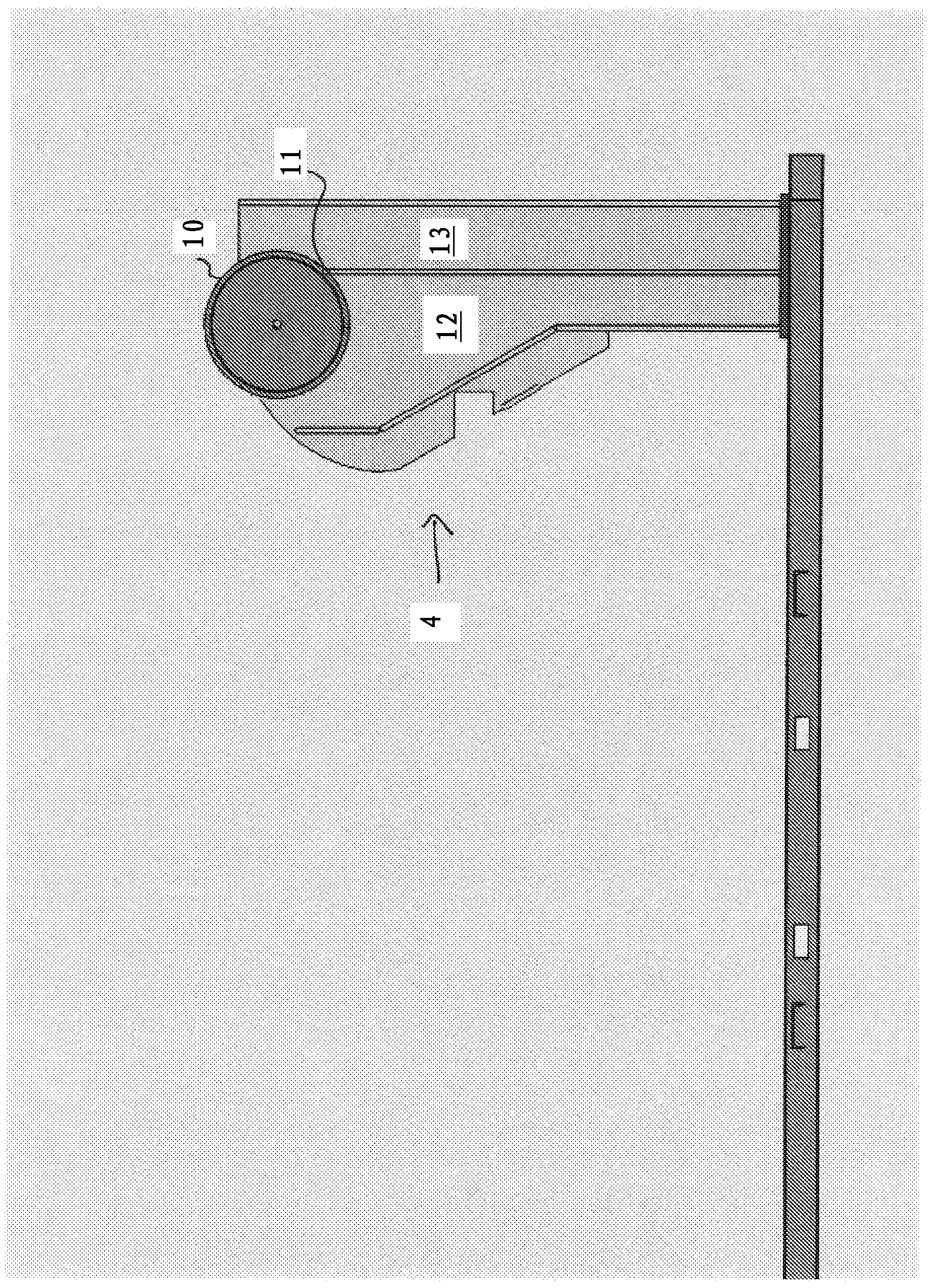

[0019] figure 1 and figure 2An embodiment of a modified dissolved air flotation (DAF) system 1 is shown. DAF system 1 includes air saturation system 2 , separation unit 3 , and rotary screen assembly 4 . The air saturated system 2 produces white foam by saturating atmospheric air into the water. The air saturation system 2 has a white foam outlet 18 from which the white foam exits. The separation unit 2 has two main compartments, a separation vessel 5 and an effluent tank 6 . Liquid / solid separation takes place in the separation vessel 5 and the purified liquid moves into the effl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com