Tail gas scrubber and method of use thereof

A tail gas scrubbing and tail gas technology, applied in the direction of separation methods, use of liquid separation agents, chemical instruments and methods, etc., can solve the problems of loss of economic benefits, production reduction, etc., and achieve less process links, reduce water storage, and be easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

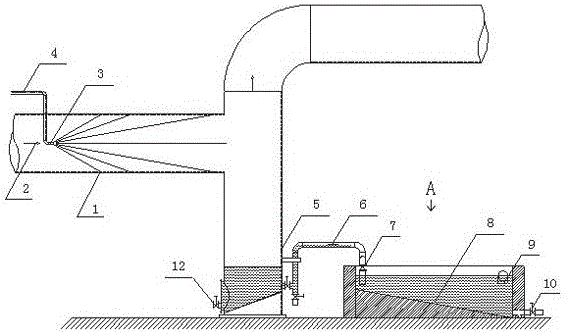

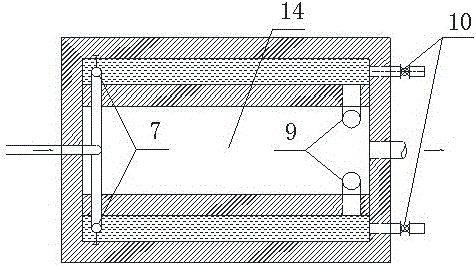

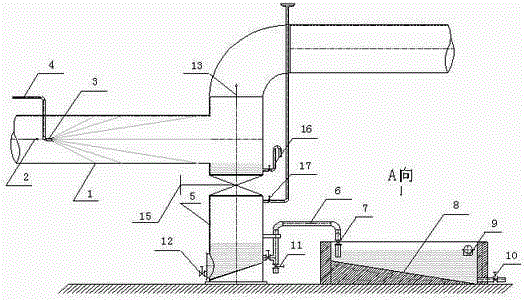

[0034] Such as figure 1 , figure 2 Shown: an exhaust gas cleaning device, which includes an exhaust gas pipeline 1, a fluid spray gun 3, a liquid collector 5, a differential pressure drain pipe 6, a drain valve 7, an inclined plate sedimentation tank 8, a tar filter 9, a sewage valve and a clean water tank 14. The tail gas pipeline 1 communicates with the liquid collector 5, and a fluid spray gun 3 for spraying circulating water 4 is provided in the tail gas pipeline 1. The liquid collector 5 is connected to the inclined plate sedimentation tank through the differential pressure drain pipe 6 and the drain valve 7. 8 connected, the lower part of the liquid collector 5 and the lower end of the inclined plate settling tank 8 are provided with a first sewage valve 12 and a second drain valve 10, and the upper part of the inclined plate settling tank 8 is provided with a tar filter 9, The outlet of the tar filter 9 is provided with a clear water pool 14; the left and right sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com